Huge Capacity Qt10-15 Concrete Kerbs/Hollow Block/Brick Making Machinery Paving Interlocking Paving Stone Making Machine Factory Hot Recommended in Botswana

Shandong Weida Construction Machinery Company- After-sales Service:24 Hours Online

- Warranty:1 Years

- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Vibration Molding

Base Info

- Model NO.:QT10-15

- Model No.:Qt10-15 Kerbs Making Machine

- Productivity:12000-14400 Pieces 40X20X20cm Blocks ,8 Hours

- Dimension:3500X2300X2930mm

- Pallet Size:1150X900mm

- Mixer Model:Js750,Js1000

- Processing Method:Hydraulic Pressure

- Voltage:220-440V

- Rated Pressure:21MPa

- Vibration Force:100kn

- Host Machine Power:44kw

- Cycle Time:15-25s

- Workship Areas:300m2

- Vibration Frequency:4500r,Min

- Weight of Host Machine:13t

- Selling Point:Durable, Long Service Life

- Transport Package:Standard Export Packing

- Specification:Q235B Jigang steel

- Trademark:weda

- Origin:China

- HS Code:8474802000

- Production Capacity:120sets,Month

Description

SPECIFICATIONS FOR QT10-15 Concrete Kerbs making machineMachine name QT10-15 Rated pressure 21Mpa Dimension 3500x2000x2930mm Forming Cycle 15-20s Vibration form Platform vibration Weight 10000kg Working area 2000 sq.m Pallet Size 1150x900mm

A Block Production Capacity

The Concrete Kerbs capacity depends on this forming machine and it is also an essential part of the

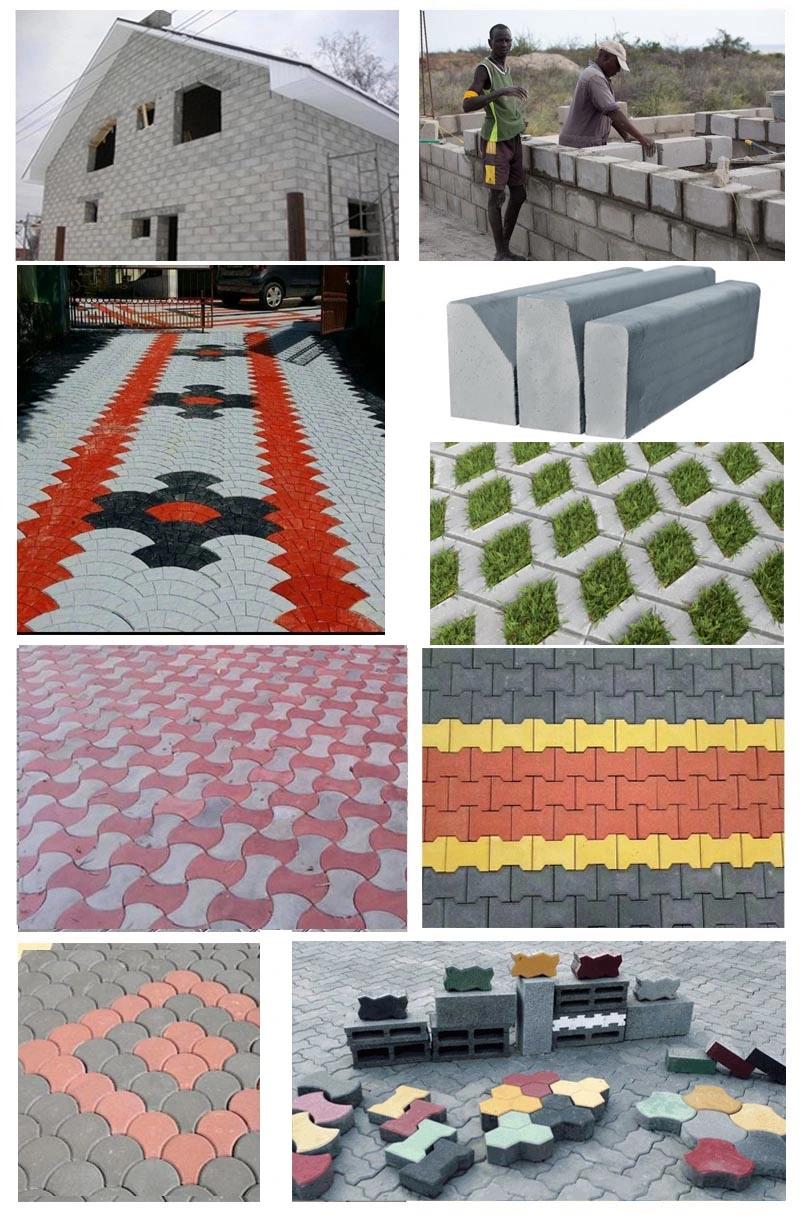

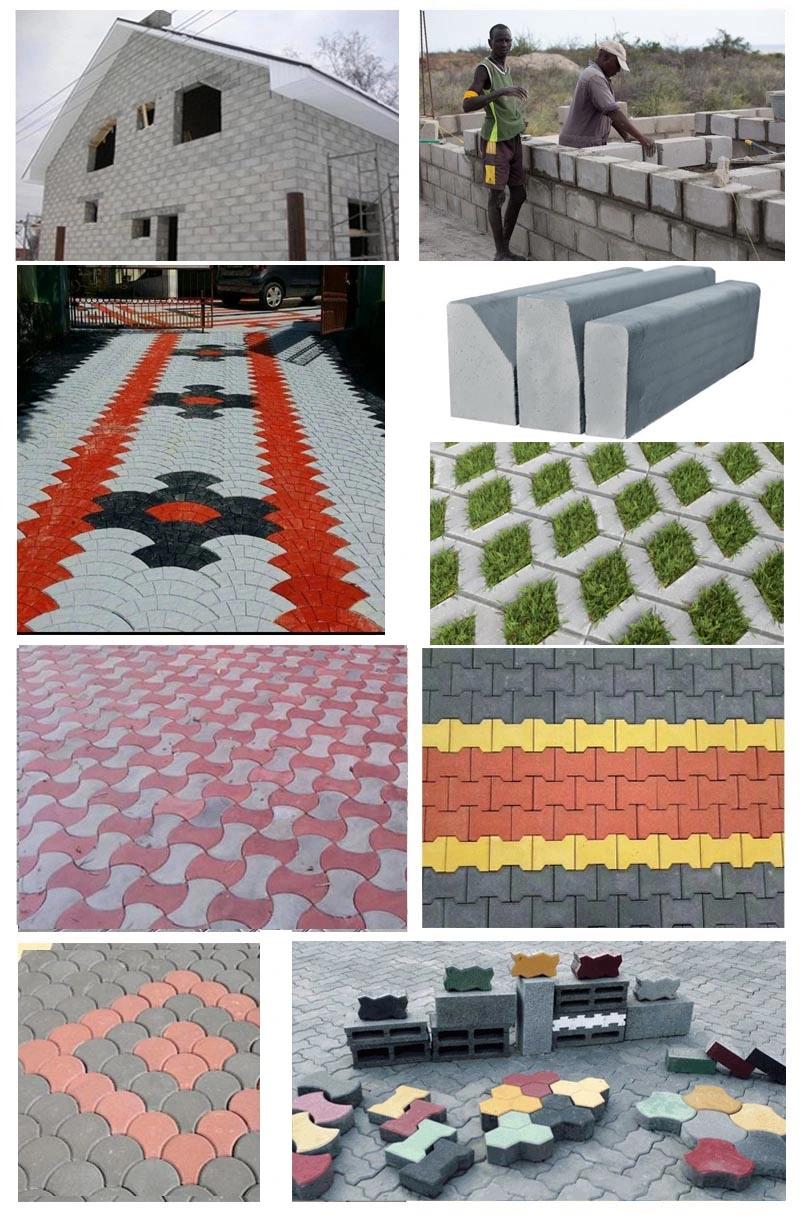

whole production line. You can change molds on these parts to make different shapes

of colored paving blocks, hollow bricks, and curbstones.NO

Size(LXWXH)

Reference photos Pcs/Mould Pcs/Hour Pcs/shift 1 400x200x200mm

10 1500-1800 12000-14400 2 400x100x200mm

18 2700-3240 21600-25900 3 230x110x70mm

40 6000-7200 48000-57600 4 200x100x60 color paving brick

32 4800 38400 5 S paver blocks

20 3000 24000

Different shaps of colored paving blocks, hollow bricks, and Concrete Kerbs production by one machine only

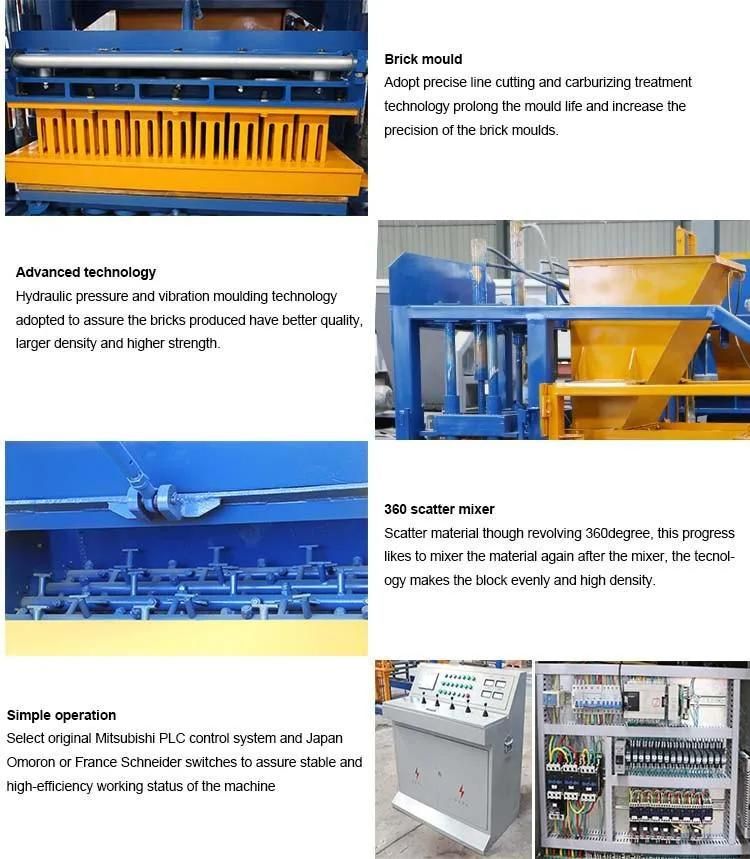

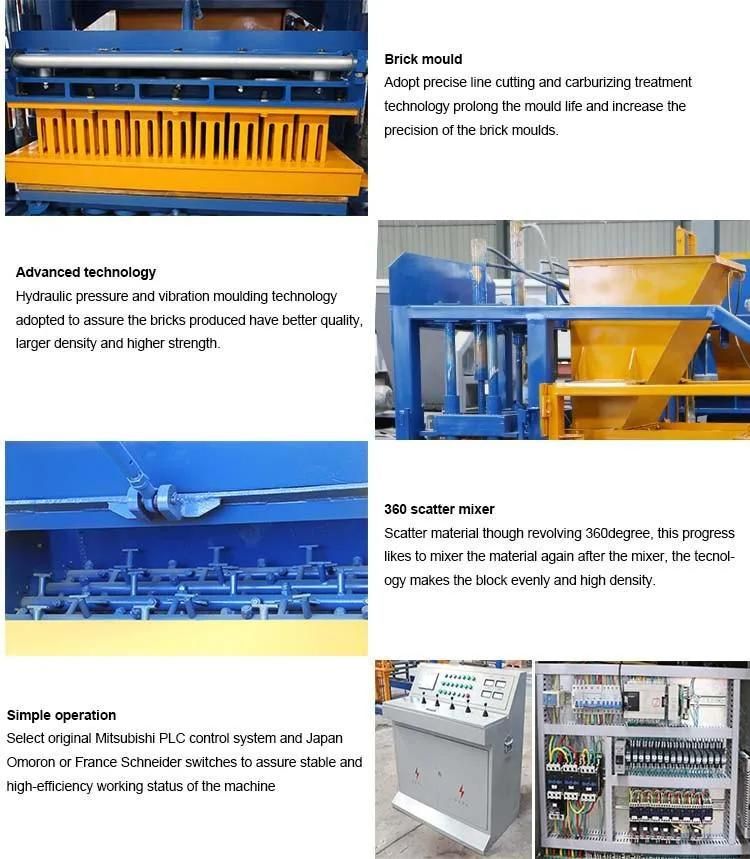

C Programme PLC with motor electronic parts

• The Concrete Kerbs making machine production process is controlled by PLC and fitted with a remote control device. for PLC control system, we usually use Japan Mitsubishi or Germany Siemens Brand

• The electricity motor for the host machine we use Germany Siemens motor, for other parts, we use CE motor.

• about the switches, we will use Europe famous brand or China CHNT

D Machine loading photos

E Hollow Interlock Block Concrete Kerbs making machine in client site

• Rakes in several rows make sure raw concrete materials fed well-distributed.

• The demolding synchronizer avoids the damage to concrete products.

• The vibration system for concrete curbs contains two-part, one is an up-mold vibration box, it is an electric motor to supply the power for the up-mould vibration box. And the down mold, there has one big vibration. when the scatter material work finish, the hydraulic power with the two vibration force will assure the good density of Hollow Interlock Blocks, solid pavers blocks, and concrete curbs..etc

Shandong Weida Construction Machinery CO., Ltd is located in Linyi City, Shandong Province, China. With RMB 16 million investment and 53,000 square meters area,

We are always developing good and reliable concrete block machinery, AAC block machines...etc Construction machinery with international standards to meet clients' demands(people-oriented, leading technology, winning quality, and serving user ).

We had exported to more than 100 countries. We have more than 60 technicians to ensure superior installations and after-sales service to assist clients to install the machine and perform the proper training abroad.

We warmly welcome customers from all over the world come to visit our factory and discuss long term cooperation. we are 24 hours service on you!

Thank you!

A Block Production Capacity

The Concrete Kerbs capacity depends on this forming machine and it is also an essential part of the

whole production line. You can change molds on these parts to make different shapes

of colored paving blocks, hollow bricks, and curbstones.

Size(LXWXH)

Different shaps of colored paving blocks, hollow bricks, and Concrete Kerbs production by one machine only

C Programme PLC with motor electronic parts

• The Concrete Kerbs making machine production process is controlled by PLC and fitted with a remote control device. for PLC control system, we usually use Japan Mitsubishi or Germany Siemens Brand

• The electricity motor for the host machine we use Germany Siemens motor, for other parts, we use CE motor.

• about the switches, we will use Europe famous brand or China CHNT

D Machine loading photos

E Hollow Interlock Block Concrete Kerbs making machine in client site

• Rakes in several rows make sure raw concrete materials fed well-distributed.

• The demolding synchronizer avoids the damage to concrete products.

• The vibration system for concrete curbs contains two-part, one is an up-mold vibration box, it is an electric motor to supply the power for the up-mould vibration box. And the down mold, there has one big vibration. when the scatter material work finish, the hydraulic power with the two vibration force will assure the good density of Hollow Interlock Blocks, solid pavers blocks, and concrete curbs..etc

Shandong Weida Construction Machinery CO., Ltd is located in Linyi City, Shandong Province, China. With RMB 16 million investment and 53,000 square meters area,

We are always developing good and reliable concrete block machinery, AAC block machines...etc Construction machinery with international standards to meet clients' demands(people-oriented, leading technology, winning quality, and serving user ).

We had exported to more than 100 countries. We have more than 60 technicians to ensure superior installations and after-sales service to assist clients to install the machine and perform the proper training abroad.

We warmly welcome customers from all over the world come to visit our factory and discuss long term cooperation. we are 24 hours service on you!

Thank you!