2022 New Design Red Clay Bricks Machine Tunnel Kiln for Burning Bricks Modern Bricks Factory

Xi'an Brictec Engineering Co., Ltd.- After-sales Service:on Site Installation & Commissioning

- Warranty:3 Years

- Certification:ISO9001: 2000, ISO 9001:2008, CE

- Customized:Customized

- Automatic Grade:Automatic

- Type:Concrete Iron Molding Machinery

Base Info

- Cutting Frequency (Time/Min.):30

- Cut Billet Length(mm):>500

- Working Pressure (MPa):0.6~0.8

- Total Power:5.75

- Dimensions(mm):4300×1140×2065

- Method:Autoclaved Aerated Concrete

- Processing:Brick Production Line

- Product:Brick

- Brick Raw Material:Concrete

- Automation:Automatic

- Transport Package:Sea Worth Container

- Specification:13000*11000(mm)

- Trademark:BRICTEC

- Origin:China(Mainland)

- HS Code:84749000

- Production Capacity:15000-21000(Standard Brick ,H)

Description

12~16 TK (bdt)

Production Process :

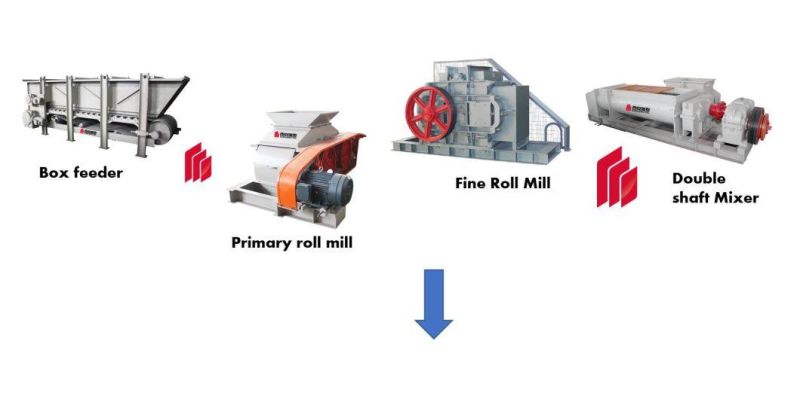

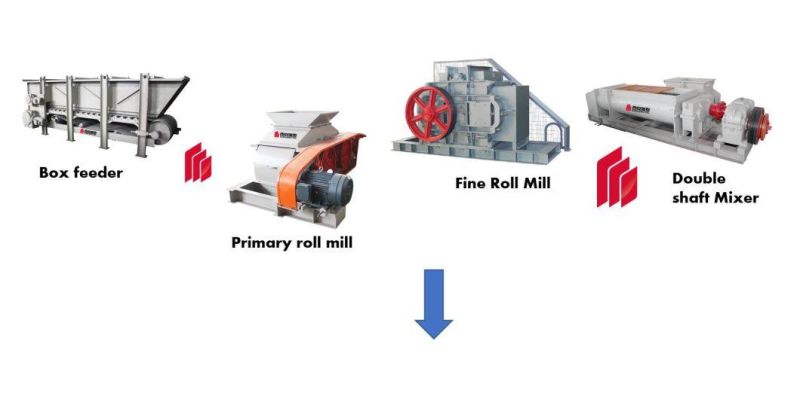

Part 1: Clay Processing Machines & Bricks Shaping Machine:

Doube stage Vaccum Extruder for bricks Shaping

∨

Automatic bricks cutting & Loading system

∨

Rack Tunnel Dryer for bricks Drying

∨

Dried bricks unloading & setting on Kiln car

Dried bricks unloading & setting on Kiln car

∨

Tunnel Kiln car loading & Transporting to Tunnel Kiln for Firing

Tunnel Kiln car loading & Transporting to Tunnel Kiln for Firing

∨

Tunnel Kiln with coal burning system for bricks firing

Tunnel Kiln with coal burning system for bricks firing

∨

Fully Automatic Coal feeding & Firing system

Fully Automatic Coal feeding & Firing system

∨

Finished bricks packing system

∨

Finished bricks packaging & storage

Finished bricks packaging & storage

Production Process :

Part 1: Clay Processing Machines & Bricks Shaping Machine:

Doube stage Vaccum Extruder for bricks Shaping

∨

Automatic bricks cutting & Loading system

∨

Rack Tunnel Dryer for bricks Drying

∨

Dried bricks unloading & setting on Kiln car

Dried bricks unloading & setting on Kiln car ∨

Tunnel Kiln car loading & Transporting to Tunnel Kiln for Firing

Tunnel Kiln car loading & Transporting to Tunnel Kiln for Firing ∨

Tunnel Kiln with coal burning system for bricks firing

Tunnel Kiln with coal burning system for bricks firing ∨

Fully Automatic Coal feeding & Firing system

Fully Automatic Coal feeding & Firing system ∨

Finished bricks packing system

∨

Finished bricks packaging & storage

Finished bricks packaging & storage