Factory Manufacturing Qt6-15 Concrete Solid Brick Machine Paver Hollow Block Making Machine

Linyi Raytone Machinery Imp&Exp Co., Ltd.- After-sales Service:Provided

- Warranty:3 Years

- Certification:CE, ISO

- Customized:Non-Customized

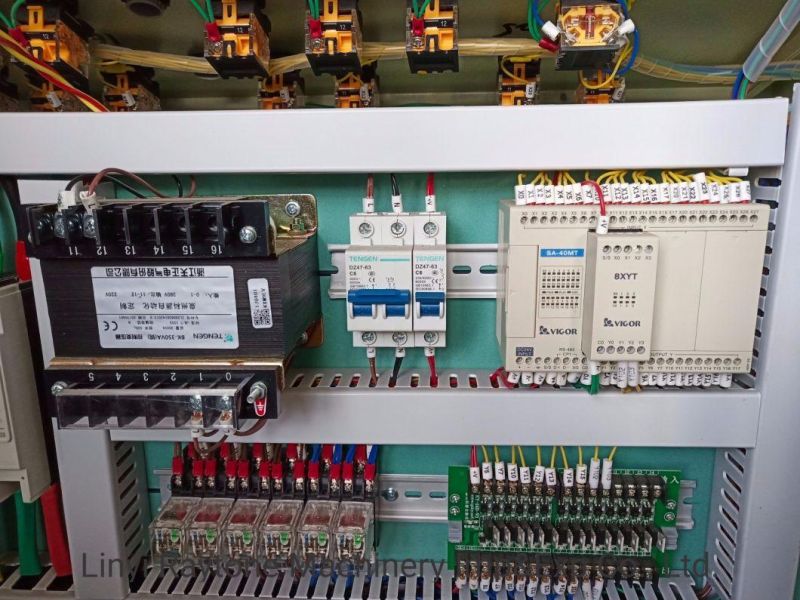

- Automatic Grade:Automatic

- Type:Concrete Iron Molding Machinery

Base Info

- Model NO.:QT6-15 block making machine

- Processing:Brick Production Line

- Method:Hydraulic Pressure

- Product:Brick

- Brick Raw Material:Concrete

- Automation:Automatic

- Tolerance:0.5mm

- Condition:New

- Workshop Area:200m2

- Dimension(L*W*H):3500X1700X2930mm

- Labor Required:15 Person,Shif

- Transport Package:Suitable for Sea Transportation

- Specification:L: 1350-4300mm, W: 1460-2300mm, H: 1800-3090mm

- Trademark:RAYTONE MACHINERY

- Origin:Linyi, Shandong

- HS Code:84748090

- Production Capacity:10800-12600PCS,Shift for 400*200*200 Mm Block

Description

1. Dimension

3000×2200×2950mm

Moulding area

800×820mm

Moulding period

15-20S

Pallet Size

980×900×25mm

Weight

12.5T

Voltage

380V

Host machine power

34KW

Vibration force

60KN

Capacity

93.55KVA

Mixer model

JS750

Water Consumption

9T/day

Size LXWXH

Pcs/Mould

Pcs/8Hours

Hollow block 400X100X200mm

14

16800-23520

Hollow block 400X150X200mm

10

12000-16800

Hollow block 400X200X200mm

8

9600-13440

Hollow block 400X250X200mm

6

7200-10100

Solid block 240X115X53mm

42

60480

Paver 200X100X60

28

33600

Paver 200X163X60

12

14400

3.simple block machine line area

workshop

200m2

office

100m2

Total area

2000m2

4.Worker amount

PLC Operator

1

Material loader

1

Forklift Driver

1

Feeding pallet

1

Maintainer

1

Transport wet block

2

Total workers

7

Batching Plant::This is the starting point of the Production process. It consists of three loading bins and one weighing bin. It also contains blet conveyers to convey materials from loading bins to weighing bin. Batching and weighing is done by PLC control. We can load three different types of material into the loading bin.

Three Hopper

Two Hopper

Screw Conveyer (Optional fitment): loading bins of the This is instrumental for transporting Fly Ash from the silos(optional fitting) or cement hopper (optional fitting) to the Batching Plant.

Conveyer Belt: When the Batching plant's weighing bin trips according to the PLC control, the material comes to this conveyer belt. The material is then carried to the Mixture Machine.

Concrete Mixture Machine: All the ingredients are mixed in this mixture machine. The mixing time and speed is controlled by PLC. The inbuilt water pump adds water to the mix automatically, as per requirement

Machine Showing during work

oil cylinder Detailed show

More Picture About Machine

Blocks Shows

PLEASE CONTACT US FOR FURTHER DETAILS