Global Shining Acrylic Corian Solid Surface Production Line

Qingdao Global Shining Equipment Engineering Co., Ltd.- After-sales Service:12 Months

- Warranty:12 Months

- Certification:CE, ISO

- Condition:New

- Customized:Customized

- Automatic Grade:Automatic

Base Info

- Model NO.:2440*760 or Customized

- Structure:Horizontal

- Transmission Method:Machinery

- Company Name:Global Shining

- Production Name:Acrylic Corian Solid Surface Production Line

- Advantages:Economic

- Color:White,Black ,Blue, Silver ,Red or Customized

- Advantage:Efficient

- Operation:Simple Operation

- Transport Package:Standard Packing

- Specification:2440*760,3050*760,3680*760mm etc.

- Trademark:GLOBAL SHINING

- Origin:Qingdao

- HS Code:8474809090

- Production Capacity:10sets,Month

Description

Basic Info.

Model NO. 2440*760 or Customized Structure Horizontal Transmission Method Machinery Company Name Global Shining Production Name Acrylic Corian Solid Surface Production Line Advantages Economic Color White,Black ,Blue, Silver ,Red or Customized Advantage Efficient Operation Simple Operation Transport Package Standard Packing Specification 2440*760/3050*760/3680*760mm etc. Trademark GLOBAL SHINING Origin Qingdao HS Code 8474809090 Production Capacity 10sets/MonthProduct Description

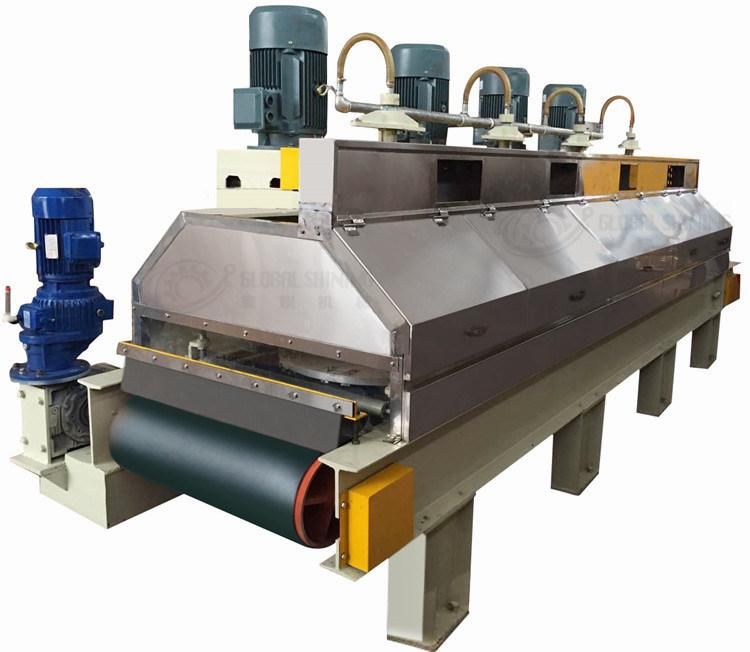

GLOBAL SHINING Acrylic Corian Solid Surface Production Line

Product Description

Acrylic Corian Solid Surface Production Line is a set of equipment that our factory has meticulously developed for Solid Surface production. Various kinds and sizes can be produced to achieve the natural marble effect.

The equipment is of simple operation, simple structure, simple maintenance and high production efficiency.

- Crushing system

- Mixing system

- Auto vacuum pouring and casting system

- Heating and consolidation system

- Cutting system

- Sanding system

- Polishing system

- Packing system

Working Principle

We firstly need to crush the material into needed particles by the Crushing system.

The resin, ATH and needed particles are put together into the Mixing tank; Mix machine is controlled by frequency changer, so the materials can be mixed quickly and no color error.

After mixing the mixed raw material and auxiliaries are sent into the Auto vacuum pouring and casting system. The casting machine, which use the vacuum pump through special process is suited for solid surface resin's component. It can work durably in vacuum condition. The reagent pump and screw are made of the special alloy, they are durable and anticorrosive.

The following is casting out the mixed raw material to the heating and conveying line.

After that the solid surface will be transported to the automatic cutting system and cut into required size.

Sanding and calibrating machine system is very important for accurate thickness setting. Sanding pad is controlled by CVT, and change feeding speed accordingly to ensure sanding quality. High-strength motor and top brand bearing ensure best performance.

Polish system provides polishing service for the solid surface, and has a stable frame structure and the pressure adjustable contact rollers. Through the low speed and adjustable downward pressure of the contact roller, the circular abrasive belt which is covered outside the contact roller polishes to get needed brightness on the solid surface.

After film cover and coding machine the finished solid surface will be packed by packing system.

The production line is running in a high automation and intellectualization without pollution.

Packaging & Shipping

Wooden box or wooden pallets.

Standard packing.

Our Services

Installation, commissioning, training:

Two technicians (one is Technical Engineer, the other one is electrical engineer) will be sent to buyer's factory to guide all of the procedure, including installation, commissioning, staff training.

Company Information

Qingdao GLOBAL SHINING Equipment Engineering Co., Ltd. is a group company of project contracting and technological transfer on solid surface (corian) production line machinery. Nowadays, machinery with core technology is fully independently researched and developed, designed, and self-manufactured. Specifically, its main procedure is consultation, design, production, debugging (in our factory), packing and delivery, commissioning (in client's factory), training and technical transfer etc.

Global Shining's technological team includes senior executives from state-owned enterprises with more than 30 years of experience serving as our consultants and innovative young people with PhD graduates etc. on mechanicalness, electricity, chemical and automation. More concretely, both chemical consultant and formula engineer are the technician of first generation in China.

Global Shining's inland clients are state-owned enterprises, foreign companies (South Korea, USA, TW etc.), quoted and group companies etc. Meanwhile, Global Shining exports machinery and technology mainly to Saudi Arabia, India, Kazakhstan, Bangladesh, Ethiopia, and Nigeria etc. 22 countries.

Besides the above, we could also suggest our clients on plant design, raw material source and necessary on-site check on behalf of buyer's requirement.

FAQ

Anywhere, anytime, contact with GLOBAL SHINING, you will get what you want.