Vertical Glass Washing and Drying Machine 1800 for Insulating Window Door Glass, Glazing Bead Window, Curtain Wall Glass

JINAN MAG GROUP CO., LTD.- Warranty:36months

- Condition:New

Base Info

- Model NO.:1800

- Certification:ISO, CE

- Automatic Grade:Automatic

- CNC or Not:not CNC

- Voltage:380V

- Application:Glass Washing

- Total Power:15kw

- Transport Package:by Non-Fumagation Plywood Case

- Specification:6100*2100*2650(mm)

- Trademark:MAG

- Origin:Jinan

- HS Code:84752990

- Production Capacity:300 Sets,Year

- Package size per unit product:610.00cm * 210.00cm * 265.00cm

- Gross weight per unit product:2500.000kg

Description

Basic Info.

Model NO. 1800 Certification ISO, CE Automatic Grade Automatic CNC or Not not CNC Voltage 380V Application Glass Washing Total Power 15kw Transport Package by Non-Fumagation Plywood Case Specification 6100*2100*2650(mm) Trademark MAG Origin Jinan HS Code 84752990 Production Capacity 300 Sets/YearPackaging & Delivery

Package size per unit product 610.00cm * 210.00cm * 265.00cm Gross weight per unit product 2500.000kgProduct Description

BX1800V Vertical Glass Washing and Drying MachineMain features

1. Washing section and water system adopt complete stainless steel or rot proof materials.

2. It has 3 pairs of glass washing soft brushes for coated glass and LOW-E glass.

3. Drying section adopts rubber roller to scrape of the water,and use the hot wind to dry the glass.

4. The transmit system of washing machine adopts unlimited speed adjustment to realize high efficiency of application.

Technical Parameters

| Model | BX1800V |

| Power voltage | 380V 50Hz |

| Max glass size | 1800*2500(mm) |

| Min glass size | 400*400(mm) |

| Transmission speed | 1-5m/min |

| Thickness of washing glass | 3-19mm |

| Power rate | 15Kw |

| Overall dimmension | 6100*2100*2650(mm) |

| Weight | 2500kg |

Different model optional:

Different model optional:| Model | MAG1600BXV | MAG 1800 BXV | MAG 2000 BXV | MAG2200BXV | MAG 2500 BXV |

| Input voltage | 380V 50Hz | 380V 50Hz | 380V 50Hz | 380V 50Hz | 380V 50Hz |

| Input power | 14kw | 15 kw | 19kw | 26kw | 28kw |

| Max glass size(mm) | 1600*2000 | 1800*2500 | 2000*2500 | 2200*3000 | 2500*3500 |

| Min glass size(mm) | 500*300 | 500*300 | 500*300 | 500*300 | 500*300 |

| Transmission speed | 1-5m/min | 1-5m/min | 1-5m/min | 1-5m/min | 1-5m/min |

| Thickness of washing glass | 3-19mm | 3-19mm | 3-19mm | 3-19mm | 3-19mm |

| Overall dimension(mm) | 6600x1300x2650 | 7800x2100x2850 | 8500x2100x3050 | 9000x2150x3250 | 9000x2150x3400 |

| Weight | 1500kg | 2500kg | 3000kg | 3400kg | 3700kg |

1. Input Conveyor • Vertical conveyor with guide roller support wall at 6 degree incline for glass load and transport with washing machine start-up synchronization.

• Professional double side resin painted high-density plywood with steel frame guarantee a smooth transport of the glass and no deform with environment change

• Bottom roller and back roller are made of high quality polyurethane with long life and no mark on glass

• Automatic Low-E distinguishing system

2. Glass washing-drying machine

For continuous cleaning and drying of glass plates

• Compact, efficient glass plate washing machine

• Inverter control of the brush rotating speed perfectly protects the high level Low-E glass.

• Washing speed is adjustable under different temperature

• Roller distance be automatically adjusted according to the thickness of the glass

• 3 pairs of brushes with 2 pairs for soft coating Low-E processing

• Maintenance-free, water-proof bearings

• Brush drives, water pumps and air blower are automatically switched-off if production is interrupted

• Transport in drying zone without a real contact of glass plate in front side

• The main structure is made of stainless steel and all the inside parts are water-proof material. Drying zone with sound protection

• Environmentally efficient, energy saving design and water-recycle system

• Water and air heater are equipped

• Blower get air from outside with filter recycling system to guarantee a clean inside condition for the washed glass. Optimized blower apply high pressure with low power consumption(11kW) ensures the glass is completely dry.

• Easy integration in glass production lines with other equipment

• Water filter equipped for best washing performance and water saving

3. Inspecting Conveyor 1&2

For gentle transport of glass plates and insulating glass units

• Basic design with one drive

• Rollers are safely arranged between steel elements, easily replaced

• Smooth support wall surface without chafing points preventing accidents, easy to keep clean

• Drive of transport rollers by friction for gentle transport and less roller wearing

• Start/stop control of transport by foot switch

• Glass sensing system make every section integrated for a high productivity

• With frequency controlled drive

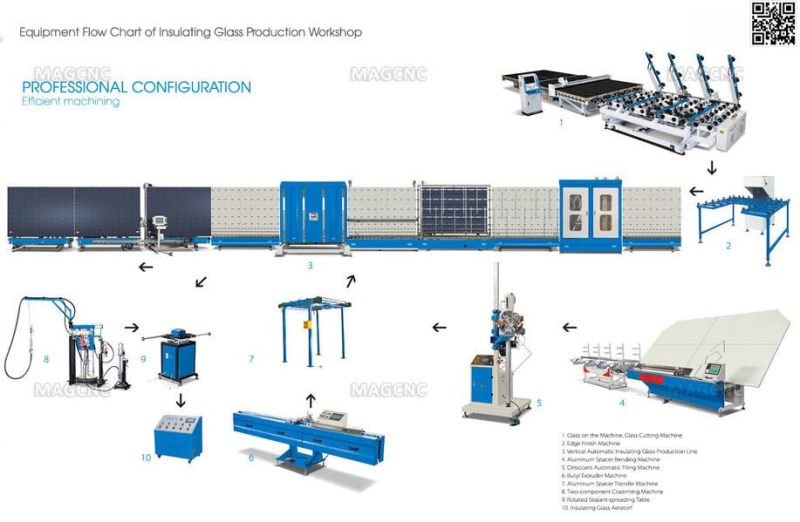

Related Machines

Related MachinesCertification

Related Machines:

Related Machines: Company:

Company: