High Efficiency and Energy Saving Grinding Machine Ball Mill

Zhengzhou General Mining Machinery Co., Ltd.- Application:Ore, Construction, Dressing

- Certification:CE, ISO9001: 2000

- Condition:New

- Type:Cement Production Machinery

- Machining Process:Welded Molding Machine

- Installation:Under The Guidance of Engineer

Base Info

- Model NO.:ball mill grinding machine

- Certificate:ISO9001: 2000

- Color:Various

- Warrenty:1 Year

- After-Sale Service:Training, Technical Support, etc.

- Delivery Time:7-15 Working Days

- Transport Package:International Packing Standard

- Specification:ISO, CE, SGS

- Trademark:TYM

- Origin:China Mainland

- HS Code:8474202000

- Production Capacity:40 Sets,Month

Description

Basic Info.

Model NO. ball mill grinding machine Certificate ISO9001: 2000 Color Various Warrenty 1 Year After-Sale Service Training, Technical Support, etc. Delivery Time 7-15 Working Days Transport Package International Packing Standard Specification ISO, CE, SGS Trademark TYM Origin China Mainland HS Code 8474202000 Production Capacity 40 Sets/MonthProduct Description

Ball MillApplication of High Efficiency Ball Mill

Ball mill is widely used for medium and fine crushing (sand making) for various hard and brittle materials such as rocks, cement clinker, quartz, iron ore and concrete aggregates, grinding materials, refractory materials, etc.

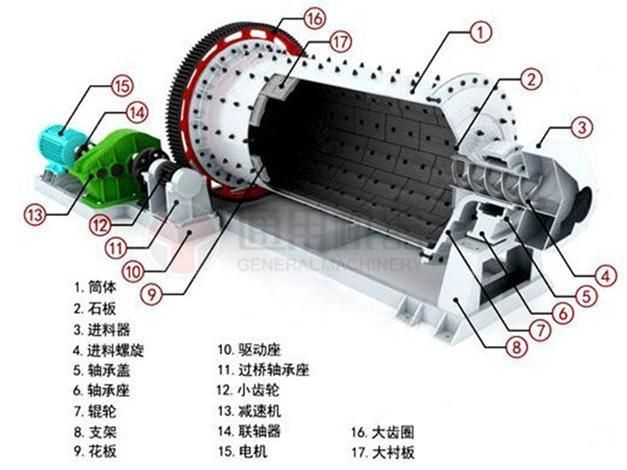

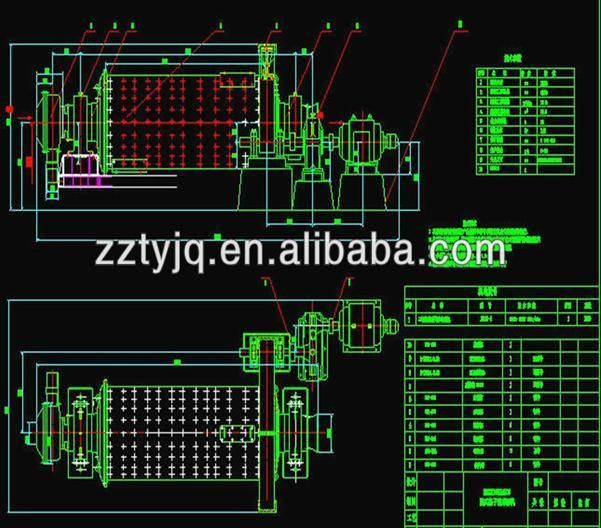

There are two ways of grinding: The dry process and the wet process. Ball mill can be divided into tabular type and flowing type according to different forms of discharging material. The structure of High Efficiency Ball Mill ISO2001

The structure of High Efficiency Ball Mill ISO2001

The ball mill is mainly composed of feeding part, input part, main bearing, barrel, transmission part, discharging part and main motor. The barrel of grinder is driven by the motor through transmission and reduction gears to rotate at a proper speed. The grinding media in the rotating barrel is lifted to a certain height and then acts by tossing and falling, by which the material is impacted and grinded. According to special requirement, the Ball Mill can be fit with air clutch, slow drive, jack system, lubricant injection device and so on. The main bearing can adopt sliding bearing, hybrid bearing, hydrostatic bearing or rolling bearing.

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

1) An efficient tool for grinding many materials into fine powder.

2) The ball mill/ fertilizer balls is used to grind many kinds of mine and other materials, or to select the mine

3) Ball mill/ fertilizer balls is widely used in building material, and chemical industry.

4) There are two ways of grinding: The dry way and the wet way.

5) Ball mill/ fertilizer balls can be divided into tabular type and flowing type according to differentexpelling mine

6) To use the ball mill/ fertilizer balls, the material to be ground is loaded into the neoprene barrel that contains grinding media.

7) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

8) The longer the ball mill/ fertilizer balls runs, the finer the powder will be.

9) Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

10) Our ball mills/ fertilizer balls have been used to grind glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals.

| Model | Speed of bucket (r/min) | Weight of ball (t) | Size of feed opening (mm) | Size of outputting feed (mm) | Production (t/h) | Power (Kw) | Weight (t) |

| Φ 900× 1800 | 38 | 1.5 | ≤ 20 | 0.075-0.89 | 0.65-2 | 18.5 | 3.6 |

| Φ 900× 3000 | 38 | 2.7 | ≤ 20 | 0.075-0.89 | 1.1-3.5 | 22 | 4.6 |

| Φ 1200× 2400 | 32 | 3.8 | ≤ 25 | 0.075-0.6 | 1.5-4.8 | 45 | 12.5 |

| Φ 1200× 3000 | 32 | 5 | ≤ 25 | 0.075-0.4 | 1.6-5 | 45 | 12.8 |

| Φ 1200× 4500 | 32 | 7 | ≤ 25 | 0.075-0.4 | 1.6-5.8 | 55 | 13.8 |

| Φ 1500× 3000 | 27 | 8 | ≤ 25 | 0.075-0.4 | 2-5 | 90 | 17 |

| Φ 1500× 4500 | 27 | 14 | ≤ 25 | 0.075-0.4 | 3-6 | 110 | 21 |

| Φ 1500× 5700 | 27 | 15 | ≤ 25 | 0.075-0.4 | 3.5-6 | 132 | 24.7 |

| Φ 1830× 3000 | 24 | 11 | ≤ 25 | 0.075-0.4 | 4-10 | 180 | 28 |

| Φ 1830× 6400 | 24 | 23 | ≤ 25 | 0.075-0.4 | 6.5-15 | 210 | 34 |

| Φ 1830× 7000 | 24 | 25 | ≤ 25 | 0.075-0.4 | 7.5-17 | 245 | 36 |

| Φ 2200× 5500 | 21 | 30 | ≤ 25 | 0.075-0.4 | 10-22 | 370 | 48.5 |

| Φ 2200× 6500 | 21 | 30 | ≤ 25 | 0.075-0.4 | 14-26 | 280 | 52.8 |

| Φ 2200× 7500 | 21 | 33 | ≤ 25 | 0.075-0.4 | 16-29 | 475 | 56 |

Company information:

Company information:Zhengzhou General Mining Machinery Co., Ltd was founded in 2004, aiming to serve the need in mining, metallurgy, construction, chemical industry etc. We manufacture TYM brand Mining Machinery which are 100% of our own design, production detection and marketing.

What distinguishes our machine from other 's worldwide is our invention and innovation on practical and easy crushing, milling system. We believe that quality should be integrated into every part of our machine.

Our main products are Powder Grinder, Raymond Grinders, High Pressure Suspention Grinders, High Pressure Micro-powder Grinders, Vertical Shaft Impact Crushers, Impact Crushers, Jaw Crushers, Cone Crushers, Vibrating Screens, Sand Washing Machines, nine series of products with more than 30 kinds of specifications.

They are all designed, produced, manufactured and tested in accordance with the standard of ISO9001: 2000 international quality system standard. Our products are recognized as quality products by technical supervision departments.

Every year, we export our grinders and crushers to South Asia, Africa, South America, middle East and other regions in quantity. And our Machines enjoy a high reputation in the foreign market. We welcome you visit our company, and hope we have chance to cooperate with you.

Pre-sale services:

(1) Device model choice.

(2) According to customer's special requirements, design and manufacture of products.

(3) Training technical personnel for clients.

(4) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program

Sales tracking:

(1)Product acceptance.

(2)Help customers to develop construction programs.

After-sale services:

(1) Free to assign a dedicated service personnel, arriving at the scene and guiding customers' installation.

(2) Equipment installation.

(3) On-site training of operators.

(4) Complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site production of 1 month, until the user' satisfaction.

We hope our perfect products and service can satisfy you, and welcome to our factory to visit. Looking forward to building long-term relationship with you!