Fully Automatic Construction Equipment Automatic Concrete Block and Brick Making Machine

Quanzhou Hawen Machinery Co., Ltd.- Warranty:One Year

- Certification:ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Vibration Molding

- Standard Hollow Block:10PCS Per Drop

Base Info

- Model NO.:QT10-15

- Zigzag Paver:28PCS Per Drop

- Vibration:Motor Vibration

- Raw Material:Crushed Stone Sand and Cement

- After Sales Service:Engineer Available to Abroad

- Power Consumption:50kw

- Transport Package:Standard Ocean Packing

- Specification:Requires to load into 40ft container

- Trademark:HAWEN

- Origin:China

- HS Code:8474809090

- Production Capacity:300 Sets, Year

Description

Basic Info.

Model NO. QT10-15 Zigzag Paver 28PCS Per Drop Vibration Motor Vibration Raw Material Crushed Stone Sand and Cement After Sales Service Engineer Available to Abroad Power Consumption 50kw Transport Package Standard Ocean Packing Specification Requires to load into 40ft container Trademark HAWEN Origin China HS Code 8474809090 Production Capacity 300 Sets/ YearProduct Description

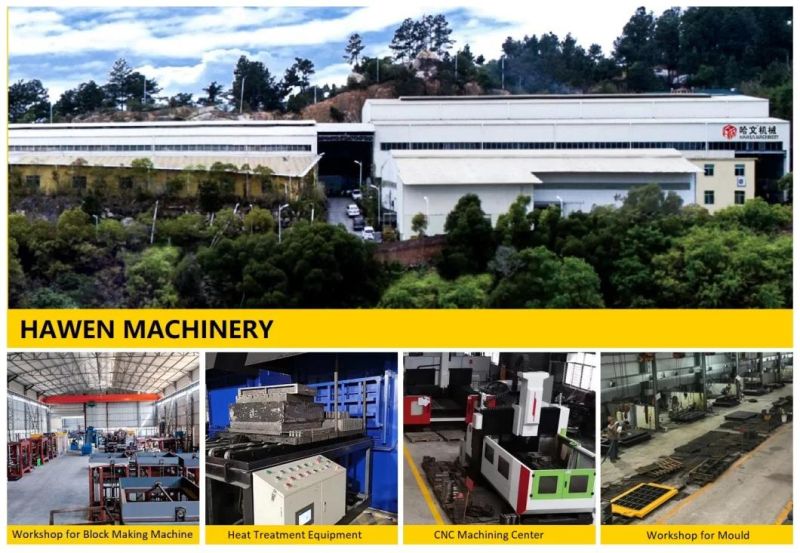

Fully Automatic Concrete Block Making Machine EquipmentFactory workshop

Brief Introduction

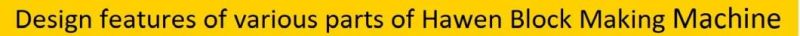

QT10-15 is a hydraulically operated universal block machine ,it is well known for its high performance and excellent flexibility. The intuitive control makes this the ideal machine for the economic production of paving stones, large slabs, kerbs, hollow /solid blocks and special products.

QT10-15 Cement brick making machine is fully automatic with PLC (Programmable Logic Controller) intelligent control.

The control system of brick making machine is equipped with SIEMENS PLC, production program, malfunction diagnosis system and remote control function,easy for operation and maintenance.

Main forming machine equipped with a basic Face-mix device,it can make the double layer paving stone just by changing the mould.

For the Vibrating box and vibrating table in our machine,it adopts the suspension integrated design structure. The vibrating table board is made of low alloy and high strength structure steel which can bear intense vibration without being destroyed and splitted . The rubber springs which are densely, evenly, optimized distributed around not only improve effect of vibration reduction for block machine, but also insure every point on the vibration table board has consistent vibrating acceleration and swing, so as to ensure the even vibration effect, ensure the consistency of concrete product height and evenness of density. Meanwhile, it also reduces the vibration noise (about 10 decibel.)

The rubber springs were placed on the vibration table of our block making machine, in order to prevent the vibrating table from declining, four knock-down orientation device with shaft and sheath slipping cooperation are installed at the four corners of the vibrating table. This can keep the vibrating table from moving at the horizontal direction during vibration.

Technical specification:

| Pallet size | mm | 1100×950×28 |

| Cycle time | S | 15-23 |

| Rate Pressure | Mpa | 31.5 |

| Vibration force | KN | 105 |

| Power | KW | 48.9 |

| Weight | T | 14.5 |

| Vibration frequency | r/min | 3800-4500 |

| Dimension | mm | 11500×4050×2800 |

Output of QT10-15 Block machine (Pallet size 1100*950mm)

Processing equipment in the workshop

Application of QT10-15 Block Making Machine at site in different countries

Container loading in workshp for customers overseas

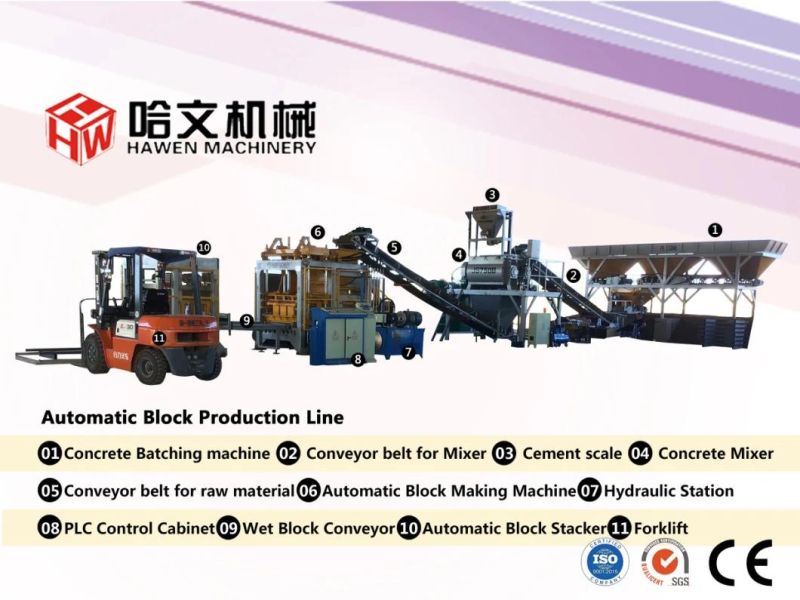

Different shape and dimension of Concrete Products can be made in our block making machine

Application of Concrete Block and Concrete Pavers

Our Service

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order

On-sale service support

Assist clients to finish the factory planning,like foundation construction, power preparation,water pool preparation,etc. Before delivery equipment to customers, complete debugging and checking,our machine will do hot testing in workshop with material. Provide a full instruction manual for the block making machine. Provide technical guidance for the installation , including installation advice and electrical connection.

After-sale service support

Send technicians to installation site for the guidance, equipment commissioning and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help.Trust us with your project, we will provide the Optimal Concrete Products Making Solution for you all the time.