Dust Making Machine Production Line

Caminix CNC Machinery (Zhejiang) Co., Ltd.- After-sales Service:24hours

- Automatic Grade:Full-Automatic

- Warranty:1 Year

- Processing Range:0.8mm-3mm Thickness

- Diameter:300-1500mm

- Length:1500mm

Base Info

- Model NO.:CMX1500

- Rolling Speed:About 3-6m,Min

- Transport Package:Seaworthy

- Specification:300-1500mm

- Trademark:CMXCNC

- Origin:China

- HS Code:8462250000

- Production Capacity:300 Per Year

Description

Basic Info.

Model NO. CMX1500 Rolling Speed About 3-6m/Min Transport Package Seaworthy Specification 300-1500mm Trademark CMXCNC Origin China HS Code 8462250000 Production Capacity 300 Per YearProduct Description

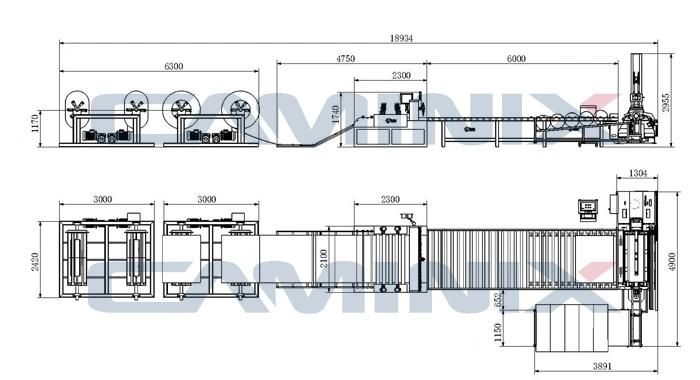

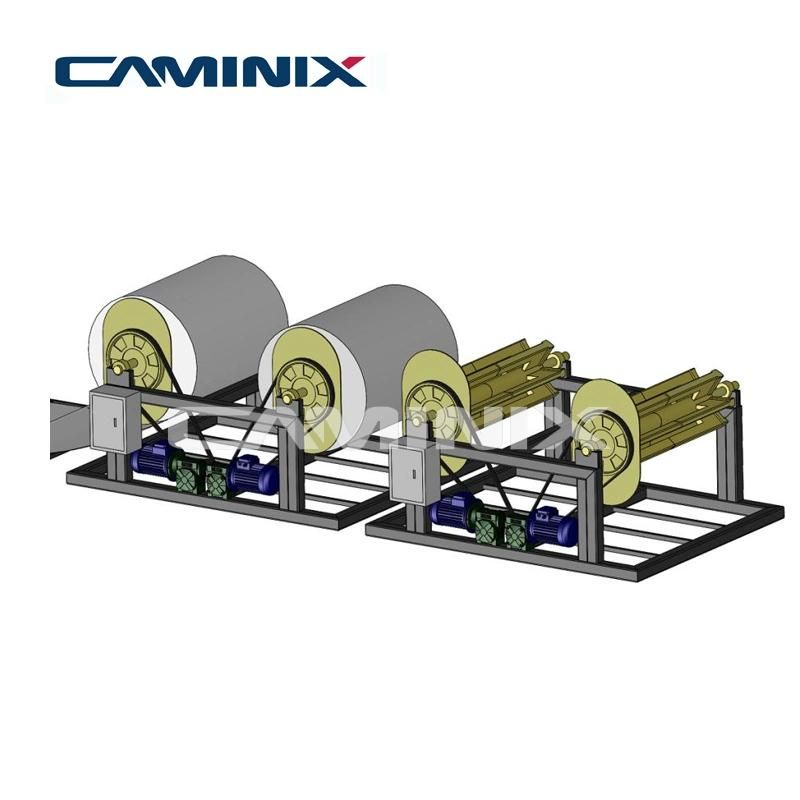

DescriptionThe equipment of the automatic production line for air duct rolling is composed of: unwinding rack, leveling machine, laser cutting, conveying transition platform, hydraulic four-roll rolling machine and other structures. It is automatic rolling used to replace the manually completed cylinders, and the basically no need manual intervention is required (except when the lifting beam cannot be used), and the equipment is simple to operate and easy to use with high productivity.

The machine is fully hydraulically driven, digitally controlled, with advanced structure, superior performance and high efficiency, in domstic and overseas market at the leading level.

Our CNC hydraulic four-roller plate rolling machine has the following characteristics:

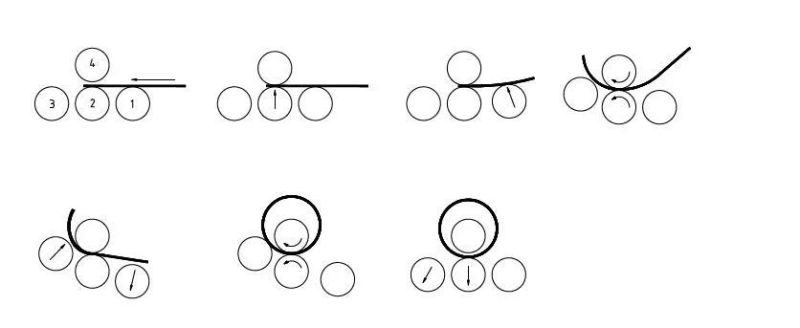

1. The side roller swings in a straight line, and the pre-bending effect is good.

2. The pressing roller and the rollers on both sides adopt Synchronization is ensured with hydraulic distribution valve and displacement sensor.

Technical Features

1. Adopt unique pre-pressure relief technology to effectively avoid hydraulic pressure

impact, improve pipeline and seal life. System build-in Recipe memory function, convenient for original data search.

1-2 Features of this machine

1. Full hydraulic drive, high efficiency and energy saving (drive power phase Compared with the traditional 60%), the rolling work is safer and more reliable than other types of rolling machines.

2. Permanent lubrication technology (no need to refuel during the bearing life)

3. The clamping pressure is adjustable (there is no slippage, and the productivity is 50%-80% higher than that of the three-roll plate rolling machine), and the pressure on the plate between the upper and lower rollers is adjustable.

The clamping force can be adjusted through the pressure regulating valve of the hydraulic station to adjust the corresponding required pressure when rolling sheets of different thicknesses and widths.

4. The cylinder body with a diameter of 1.5 times the upper roll can be rolled, and the length of the straight edge when the end of the rolled sheet is pre-bent is smaller than that of other types of sheet rolling machines.

Working Principle

Hydraulic Roller Technical Details

| Item | Part Name | Details |

| 1 | Model | CM-JYX3*1500 |

| 2 | Upper Roll Diameter | Φ150MM 42CrMo Forging |

| 4 | Lower Roll Diameter | Φ150MM 42CrMo Forging |

| 5 | Side Roll Diameter | Φ130MM 42CrMo Forging |

| 6 | Materials | Stainless Steel |

| 7 | Machining Range | 0.8-3mm |

| 8 | Max Rolling Plate Thickness | 3mm |

| 9 | Max Plate Bend Thickness | 3mm |

| 10 | Plate Max Length | 1500mm |

| 11 | Working Roll Drive Type | Upper Roll Hydraulic Motor Drive |

| 12 | Plate Yield Limit | ≤245Mpa |

| 13 | Rolling Speed | About 3-6m/min |

| 14 | Pre-bend remaining Straight Line | ≤1.5 Plate thickness |

| 15 | Full Load Min Rolling Diameter | Φ300 |

| 16 | Machine Total Power | 4KW |

Drawing