Qty10-15 Brick Making Machine, Red Brick and Concrete Stone Machine, Road Block Making Machine Qt10-15 Dongyue

Dongyue Machinery Group Co., Ltd.- Certification:CE, ISO9001: 2000, CE, SGS

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydraulic Shock

- Experience:Nearly 20 Years

- Block Machine Method:Hydraulic Pressure and Vibrate

Base Info

- Model NO.:QT10-15

- Hydraulic Station:Taiwan Jiugang

- Welding:Carbon Dioxide Welding

- PLC:Mitsubishi &Siemens

- Motor:Siemens &ABB

- AC Contactor:Schneider& Omron

- Mold:Heat Treated

- Oversea Ofice:India, Indonesia, Vietnam, Russia

- Condition:New

- Transport Package:suitable for sea transportation

- Specification:ISO9001 and CE

- Trademark:Dongyue

- Origin:China

- HS Code:84748090

- Production Capacity:50sets ,month

Description

Basic Info.

Model NO. QT10-15 Hydraulic Station Taiwan Jiugang Welding Carbon Dioxide Welding PLC Mitsubishi &Siemens Motor Siemens &ABB AC Contactor Schneider& Omron Mold Heat Treated Oversea Ofice India, Indonesia, Vietnam, Russia Condition New Transport Package suitable for sea transportation Specification ISO9001 and CE Trademark Dongyue Origin China HS Code 84748090 Production Capacity 50sets /monthProduct Description

Dongyue Machinery Group are leading cement brick making machine in China.

Our brick machine has been exported to more thn 60 countries.

Oversea offices are built in India. Indoneisa. Vietam etc.

We have 32 fly ash brick making machine plant in India.

They spread in Bhubaneshwar, Coimbatore, Rajkot, Koltata, bangalore, Indore etc.

Two after sale service centers and spare stock center are available in Ahmedabad and Bhubaneshwar.

India engineers are well trainned in China and can install the machine in India directly.

1. Advantages of qty10-15 brick making machine|red brick and concrete stone machine|raod block making machine qt10-15 dongyue:

1 )Nation standard steel and special welding technology.

2 )PLC control unite: Japan MITSUBISHI electric

3 )Hydraulic unite: Taiwan JIUGANG

4 )Switch: Japan OMRON

5 )Electrical elements: France SCHNEIDER

6 )Mould: High temperature carburizing heat treatment

7 )Host machine and mixer motor: Germany Siemens

8 )Other motors: European CE standard

2. Guarantee of qty10-15 brick making machine|red brick and concrete stone machine|raod block making machine qt10-15 dongyue:

We will supply one year guarantee about our Cement block making machine, when the client have the question,

They could call our service department number any time, we will supply per day 24 hours service.

Within one year, if the client meet the unsolvable questions, we could fly to client place to help

3. Worker requirement of qty10-15 brick making machine|red brick and concrete stone machine|raod block making machine qt10-15 dongyue:

From loading material to transport finished block we need about 4-5 person to operate the Cement block making machine whole line.

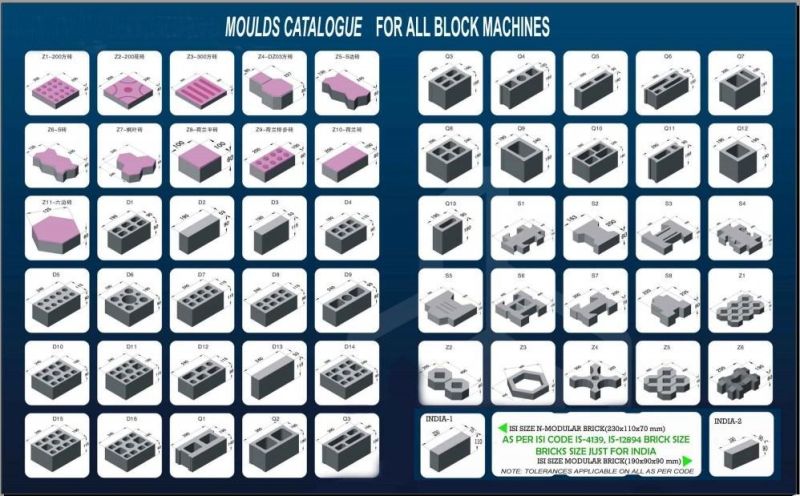

4. Samples:

5. Certification

| Dimension of host machine | 3500×2220×2850mm | Host machine power | 45.38KW |

| Moulding area | 1025×810mm | Vibration force | 100KN |

| Moulding period | 15-25S | Mixer model | JS750 |

| The size of the pallet | 1350×900×30mm | General water Consumption | 12T/every day |

| Weight of the host machine | 14T | ||

| Voltage | 380V |

(2) Production capacity

| Size(LxWxH) | Pcs/Mould | Pcs/ Hr | Pcs/ 8 Hr |

| 400X100X200 | 20 | 3000-3600 | 24000-28800 |

| 400X150X200 | 14 | 2100-2520 | 16800-20160 |

| 400X200X200 | 10 | 1500-1800 | 12000-14400 |

| 400X250X200 | 8 | 1200 | 9600 |

| 240*115*53 | 54 | 8100-9720 | |

| 240*115*90 | 25 | 3750-4500 | |

| Paver:200X100X60 | 35 | 5250 | 42000 |

| Paver:200X165X60 | 20 | 3000 | 24000 |