3100mm Metal Corrugated Barrel Type Roofing Sheet Forming Machine

Cangzhou Zhongheng Machine Manufacture Co., Ltd.- Tile Type:Colored Steel

- Certification:CE

- Condition:New

- Customized:Customized

- Usage:Roof, Wall

- Transmission Method:Electric

Base Info

- Model NO.:ZH3100

- Feature:3100mm Metal Corrugated Barrel Type Roofing Sheet

- Suitable Material:PPGI Gi

- Thickness:0.13-0.4mm

- Width:3100mm as Custom Profile

- Voltage:380V

- Speed:30m,Min

- Rollers:45# Steel as Customer Require

- Motor:5.5kw

- Control:PLC Delta

- Cutting:Hydraulic , Electric

- Key Selling Points:Easy to Operate

- Cutting Blade:Cr12 MOV

- Delivery Time:40 Days

- Warranty:2 Years

- Transport Package:Plastic File

- Specification:7.8X1.5X1.7M

- Trademark:ZH

- Origin:Hebei, China

- HS Code:8455221000

- Production Capacity:20 Sets Per Month

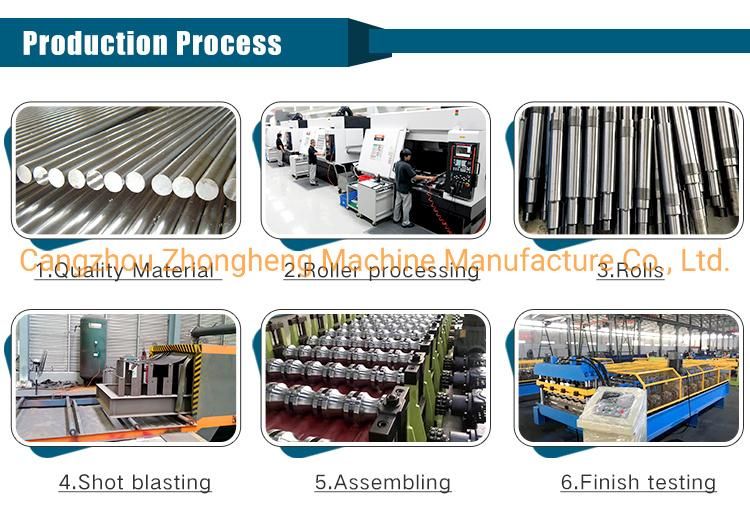

Description

2.Rolled products meet the following geometrical dimensions

Corrugated sheet size: (length × wave height × wave length):≤3100mm×18mm×76mm

<Wave height and wave length are adjustable, wave height increases, wave length decreases; conversely wave height decreases, wave length increases>

Technical performance

A,Structure description

It consists of a forming roll, a correction roll, and a frame. Four rollers share a motor ,Reducer drive.

Forming roller: the number is two pieces, when the assembly is arranged up and down, through the transmission shaft and reducer connected to the transmission molding roller operation to complete the tile in the rolling process of power.

Correction roller: The number is two. When assembling, it is arranged up and down. It is connected with the gear box through the transmission shaft and the correction roller is operated to correct the wave height and tile width of the roll forming plate.

B,Forming roller, correction roller adjustment

Forming roller, correction roller are up and down adjustable.

The forming roller lift adjustment handlebar adjusts the wave width of the unit width tile, adjusts the width of the tile width at the beginning and end of the tile, and the peak-to-peak width of the tile.

The correction roller lift adjustment handle is used to adjust the width of the forming tile and the height of the tile peak. The adjustment device has scale and dial indicators that allow precise adjustment of the required parameters.

C,Feeding platform device

Feeding platform is a frame structure, which is composed of a lower fixed frame and an upper movable frame. The movable platform is a reciprocating motion of the connecting rod crank. The reciprocating support is a linear motion bearing with high precision support, and the plate is flushed into the forming roller. Positioning the adjustable stop, the position of the stop can be precisely adjusted by the scale indication

D,Transmission Device

The power input of the entire device is the transmission of the motor gearbox through the drive shaft, the speed of the equipment is adjustable through the inverter, and the speed adjustment range is wide.

E,Electric control system

One frequency conversion control box is used to complete the control of the equipment production process.

Packing and Shipping

1. Barral type corrugated iron roofing sheet making machine roof panel forming machine need one 20/40 feet container to load .

2.We have professional technicians for loading to make sure machine has no damage.

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

Company Introduction

FAQ

1. Can you make the machine according to my design or photo type?

A: Yes. We have an experienced engineers to work out the most suitable design and production plan for the machine.

2: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation and trainning .

3.What about your warranty?

A: Within the One-YEARS period, we could supply you the replacement parts for free .

If any damaged parts caused by quality problems after two years,we will also help but customer pay the cost .

More information please send inquiry to us , you will get reply within 12 hours !

More information please send Inquiry now , will reply within 12 hours .