Compressed Soil Earth Clay Interlocking Lego Block Making Machine by Diesel Engine

Shandong Weida Construction Machinery Company- Warranty:1 Year

- Certification:CE, ISO, Soncap,Pvoc,Interteck

- Customized:Customized

- Automatic Grade:Manual

- Type:Hydroforming

- Productivity:1600-2400 Pieces 230X220X110mm Interlocks ,8 Hours

Base Info

- Model NO.:M7M1

- Labor Required:3-4 Persons

- Power:220V-440V or Diesel Engine Power

- Raw Materials:Clay,Cement,Soil,Mud

- Condition:New

- Method:Hydraulic Pressure

- Rated Hydraulic Pressure:16MPa

- Road Tyres:Movement From One Site to Other

- Shaping Cycle:15-20s

- Machine Type:Interlocing Block Making Machine

- Mold:for 230*220*115mm Hydraform Block

- Pay Mixer:Mix Rawing Material

- Weight:1500kgs

- Diesel Engine:15HP

- Transport Package:Plywood Box with Angle Iron

- Specification:Q235B Jigang steel

- Trademark:weda

- Origin:China

- HS Code:8474802000

- Production Capacity:120 Sets,Month

Description

Basic Info.

Model NO. M7M1 Labor Required 3-4 Persons Power 220V-440V or Diesel Engine Power Raw Materials Clay/Cement/Soil/Mud Condition New Method Hydraulic Pressure Rated Hydraulic Pressure 16MPa Road Tyres Movement From One Site to Other Shaping Cycle 15-20s Machine Type Interlocing Block Making Machine Mold for 230*220*115mm Hydraform Block Pay Mixer Mix Rawing Material Weight 1500kgs Diesel Engine 15HP Transport Package Plywood Box with Angle Iron Specification Q235B Jigang steel Trademark weda Origin China HS Code 8474802000 Production Capacity 120 Sets/MonthProduct Description

Compressed soil earth clay interlocking lego block making machine by Diesel Engine

Features:

1.mobile type interlocking red soil brick machine

2.Diesel/Electric powered

3.Integrated Pan mixer

4.± 2200 blocks a day

5.Interlocking soil cement blocks * 2200 blocks

6.± 60m² of walling per day

7.±10 x 72m² houses per month.

This clay brick making machine is very popular in African countries for it's cheap price and low investment.

Technical Data

| Dimension of host machine | 2580×1080×1400mm | Host machine power | 15Hp diesel engine with electric start |

| Weight of the host machine | 1200 KGS | Pressure | 16-25Mpa(30T) |

| Forming period | 15-20S | Shaping type | Hydraulic pressing |

Productivity

| Block Photo | Size(L*W*H) mm | Qty(Pcs)/Mould | Qty(Pcs)/Hour | Qty(Pcs)/8Hour |

| 230x220x110 | 1 | 200-250 | 1600-2400 |

| 230x140x110 | 1 | 200-250 | 1600-2400 |

3 Blocks

M7M1 manual hydraulic interlocking brick making machine can produce various clay interlocking bricks by changing moulds.

The following bricks are some common brick types. And also we can customize brick moulds base on your specific requirements.

Blocks material:clay /mud/erath/ soil/Laterite ,cement,water.

Blocks Formula used for interlocking blocks production Method one: 5% cement + clay:

Method two: 8% cement + clay; Method three: 10% cement + clay; Method four: 10%cement + sand + water.

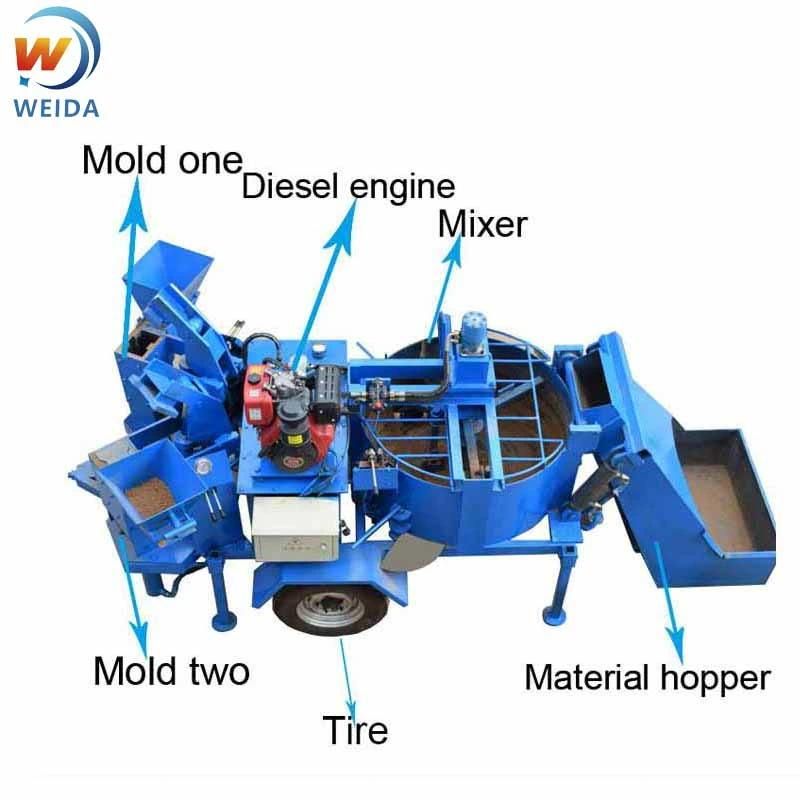

4 M7M1 machine description:

1.Function

ecological brava hydraulic brick block machines can produce various big sizes of interlocking bricks

2,Hydaulic system.

Hydraulic pressure is 16mpa, so the blocks produced are of good quality, large density and high strength.

3.Dual system

Machine can be powered by Siemens motor or Changchai Diesel engine, avoiding problem of power shortage , so it

can be used any where even in rural areas.

4.High quality of interlock bricks.

With powerful hydraulic pressure, bricks produced by the machine with big strength and large density.

With RMB 16 million investment and 53,000 square meters area, We are always developing good and

realiable machinery with international standards to meet clients demands(people-oriented, leading technology,

winning quality, and serving user ). We had exported to more than 100 countries. We have more than 60

technician to ensure superior installations and after sale service to assist clients to install the machine

and perform the proper trainning abroad.

We warmly welcome customers from all over the world come to visit our factory and discuss

Thank you !

FAQ(Questions you may have)

FAQ(Questions you may have)Q1: How can i trust your machine's quality?

Our products have been checked and got certification ISO9001, and we have exported to many countries and regions in the world,

with good reputation and quality of customer feedback. In addition, every machine is carefully tested before shipment

to ensure that the machine is operating perfectly when it comes to your hand.

Q2: What types block your machines can make?

A: Various block/brick including interlocking brick,hollow brick, solid block, interlocking paving block,curb stone.

Q3: How long is the warranty of your machine? Do you supply spare parts?

A: Our warranty period is one year generally. The spare parts tools is necessary.Of course we supply them.

Q4: How to make different size and shape brick by one machine?

A: Usually one machine can make different brick,just need to replace different mould then can make different brick.

Q5: Do you provide after-sale service?

A: Yes. We have one professional after-sale service team could solve your problems promptly and thoroughly

Q6: How to Cure Blocks?

A: Fresh Blocks are stacked and covered with black plastic to avoid moisture loss. The blocks are then watered daily to create

a greenhouse effect, allowing the cement to harden and the blocks to strengthen. Cure your blocks for a minimum of 7 days and

allow the blocks to dry to another 7 days before building. This will ensure strong good quality blocks.

7.Q: How long for delivery time after payment ?

A: Normally 15-20 days after your deposit.