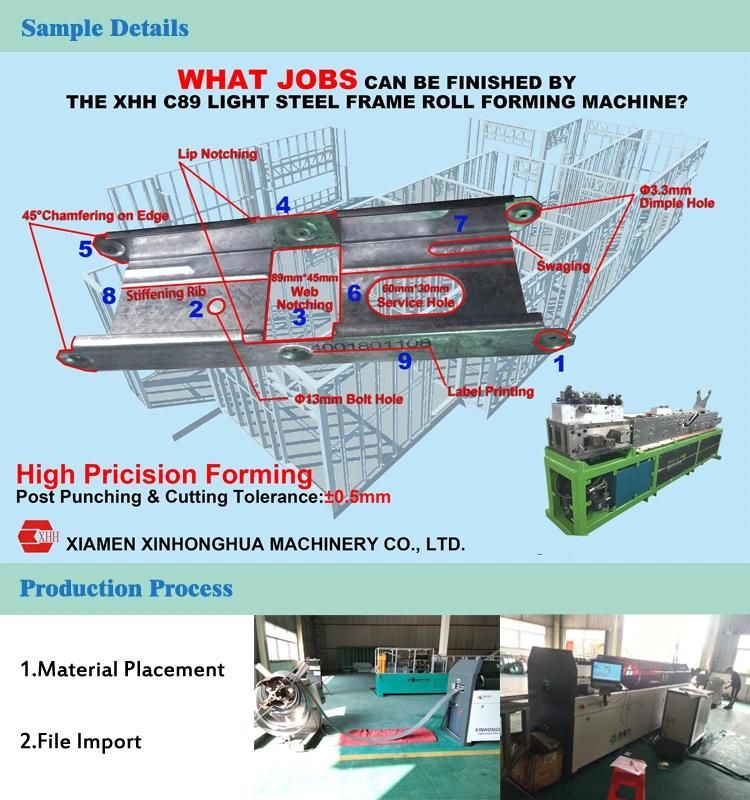

C89 Prefab House Light Gauge Steel Frame Roll Forming Machines

Xiamen Xinhonghua Machinery Co., Ltd.- Certification:CE

- Customized:Customized

- Condition:New

- Control Type:CNC

- Automatic Grade:Automatic

- Drive:Electric

Base Info

- Model NO.:C89 Light Steel Framing Machine

- Power:7.5kw

- Voltage:380V,50Hz 3phase(as Customer′s Request)

- Production Speed:Drywall Panel Frame 600-700m,H

- Profile Dimension(Web*Flange*Lip):89mm*38mm*9mm

- Feeding Material:0.65-1.2 mm G300-G550 Gi,Gl Strip

- Material Strip Width:174mm

- Accessional Un-Coiler:3t Hydraulic Steel Strip Un-Coiler

- Material of Rollers:SKD 11

- Material of Cutting Punching Die:SKD 11

- Accessional Supporting Design Software:Vertex Bd

- Transport Package:Machine Is Fixed in The Container with Steel Rope

- Specification:Dimension: 3800*800*1100mm

- Trademark:XHH

- Origin:Xiamen, Fujian, China

- HS Code:8455229090

- Production Capacity:20 Sets Per Month

Description

Size

4000*800*1100mm

Weight

2500KGS

Main Servo Motor Power

7.5KW

Hydraulic Motor Power

7.5KW

Forming Steps

7 steps forming + 2 steps reshaping

Processing Speed

C Channel Roll Forming without Punching:2700m/h

Drywall Panel Frame Roll Forming Speed:600-700m/h

Overall Production Capacity: 3-4tons/8h

Voltage

380V/50HZ/3PH

Accessories

1.Laptop Based Production Cotrolling System

2.3MT Hydraulic Uncoiler

3.Hydraulic Oil Cooling System

4.Layout Table

5 Maintainance Tool Box

6 User Manual

7.Vertex BD Steel Frame Structure Design Software

(permanent license,next annual version free update)

(USD 20,000 can be deducted from the total price if the client doesn't need the software)

Tolerence

Forming Tolerence: 0.75mm,

Punching & Cutting Tolerence:±0.5mm

Feeding Material

174mm width 0.65mm -1.2mm Thickness G300-G550

GI/GL steel strip coils

SKD11 steel with heattreatment, plate hard chrome on the surface;

Material of Blade

SKD11 with quenched treatment 6 0-62 ºC ;

XHH LGS machine features:

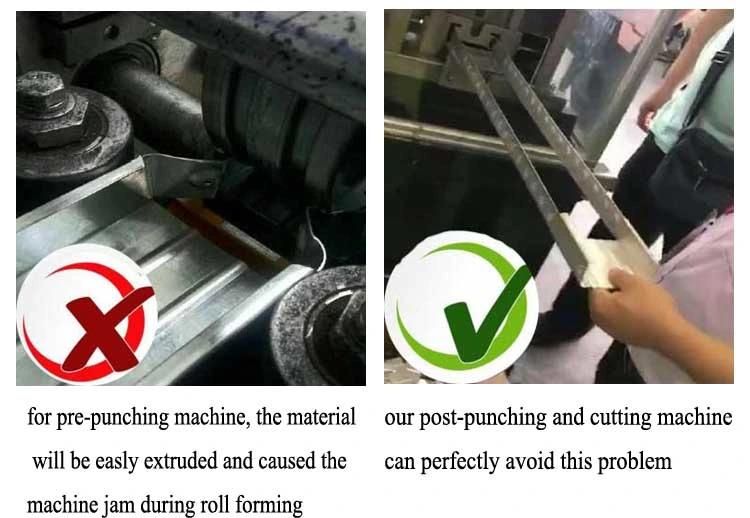

1)post-punching and post-cutting

2) Two reinforced ribs to increase the loading capacity for 28%

other company's service hole XHH service hole avoid to

break the reinforce ribs break the reinforce holes

3) XHH patent seamless end cutting: wall purlin connect to

floor purlin without gap

other company's without seamless, XHH the two ends of the vertical frame

the weight of house is only loaded can be seamless connected to the web of

by the friction of the connecting screw the bottom and top horizzontal frames,

so the weight of the house can be directly

loaded and passsed by the vertical frame

which makes the house much stronger.

4) Hydraulic oil cooling system

About 70~80% working time of the machine is for punching and cutting which will easily cause the high temperature of the hydraulic oil under a long time high pressure & high frequency working. So the machine should be equipped with refrigeration system or water cooling system