Software to Rapidly Produce Lightsteel Framing Roll Forming Machines

Xiamen Xinhonghua Machinery Co., Ltd.- Warranty:1 Year

- Tile Type:Light Steel

- Certification:CE, ISO, SGS

- Condition:New

- Customized:Non-Customized

- Usage:Roof

Base Info

- Model NO.:C89

- Transmission Method:Hydraulic Pressure

- Power(W):5.5kw

- Weight:2800kgs

- After-Sales Service Provided:Engineers Available to Service Machine

- Hydraulic Power:3.7kw

- Control System:PLC(Imported Brand)

- Voltage:380V,50Hz,3pH

- Material Thickness:0.55-1.2mm

- Roller Material:SKD-11

- Forming Steps:9steps

- Transport Package:Standard Package for Export

- Specification:3700*800*1100mm

- Trademark:XHH

- Origin:Fujian, China (Mainland)

- HS Code:845522909

- Production Capacity:20sets,Moths

Description

Size

3700*800*1100mm

Weight

2800KGS

Main Servo Motor Power

5.5KW

Hydraulic Motor Power

5.5KW

Forming Steps

10 steps for reshaping

Processing Speed

Voltage

380V/50HZ/3PH

Lip of C Profile

9mm

Tolerence Of Forming&cutting

0.75mm,0.5mm

Forming Thickness

0.55-1.2mm

Flange

38mm

Web Width

89mm

2)Main Accessories

(1) .Main Forming Machine;

(2) .Hydraulic Strip Uncoiler;

(3) .Hydraulic Punching Device;

(4) .Hydraulic Motor System;

(5) .PLC Computer Controlling System With Touch Screen;

(6) .Hydraulic Forming Cutter;

(7) .Automatic Printing Device;

(8) .Design Software;

(9) .Run Out Table;

(10) .Tools;

(11) .Operation Manual.

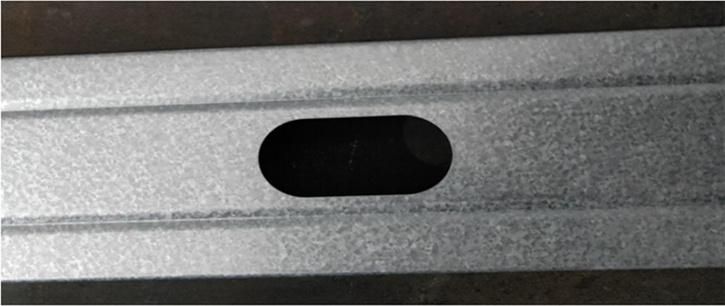

3.Profile Drawing&Holes location on C89

4. XHH LGS former with continuous web notch punching without extruding material,

By Pre-punching&post-cutting

5.Adding two enforced ribs on the web, to increase the loading capacity of frame

No enforced ribs on web Enforced ribs broken by service holes

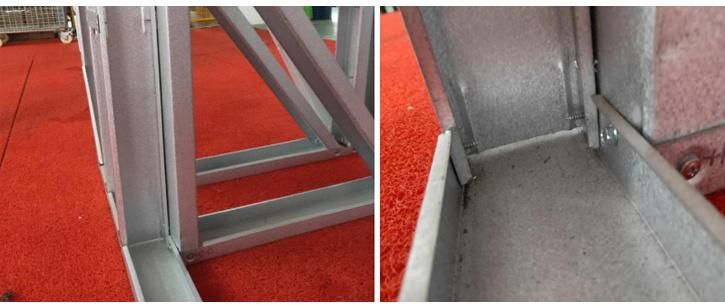

6.Seamless end cut connection Seamless end-cut connection is a patent design of XHH LGS ROLL FORMER. The two ends of the vertical frame can seamlessly connect to the web of the bottom and top horizontal frames. So the weight of the house can be directly loaded and passed by the vertical frame, which makes the house safer.( the distance between end of vertical frame and web of horizontal frame can be set between 0-4mm).

6.Seamless end cut connection Seamless end-cut connection is a patent design of XHH LGS ROLL FORMER. The two ends of the vertical frame can seamlessly connect to the web of the bottom and top horizontal frames. So the weight of the house can be directly loaded and passed by the vertical frame, which makes the house safer.( the distance between end of vertical frame and web of horizontal frame can be set between 0-4mm). Seamless end cut connectionNormally, the two ends of the vertical connection frame are not seamlessly connected to the web of horizontal frame. The weight of the house acts on the friction of the nail socket, the tension and shear force of the connecting screw.

Seamless end cut connectionNormally, the two ends of the vertical connection frame are not seamlessly connected to the web of horizontal frame. The weight of the house acts on the friction of the nail socket, the tension and shear force of the connecting screw. 7.XHH light steel frame cases reference:

7.XHH light steel frame cases reference:

Further details, please contact with: Ms Ivy