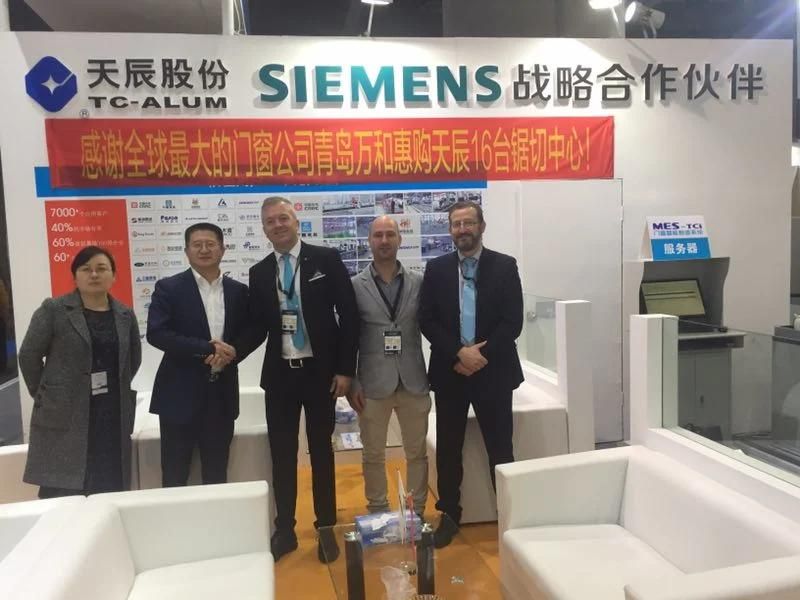

Aluminium Profile CNC Cutting Saw Center Window Door Machine

Jinan Tianchen Smart Machine Co., Ltd.- Condition:New

- Certification:ISO, CE

- Automatic Grade:Automatic

- CNC or Not:CNC

- Voltage:Customized Value

- Name:Automatic Cutting Saw Center

Base Info

- Model NO.:LJVE-CNC-6000

- Function:Cutting Raw Aluminium Profile to Certain Length

- Main Feature:Automatic

- Average Productivity:2200 Finished Cutting Pieces Within 8 Hours

- Control System:Siemens

- Application:Window Door Fabrication

- Usage:Cutting Sawing Raw Profile to Length

- Transport Package:Iron Pallet in Container

- Specification:40GPx2

- Trademark:Tianchen

- Origin:Jinan, Shandong, China

- HS Code:8461409000

- Production Capacity:30 Sets Per Month

Description

Basic Info.

Model NO. LJVE-CNC-6000 Function Cutting Raw Aluminium Profile to Certain Length Main Feature Automatic Average Productivity 2200 Finished Cutting Pieces Within 8 Hours Control System Siemens Application Window Door Fabrication Usage Cutting Sawing Raw Profile to Length Transport Package Iron Pallet in Container Specification 40GPx2 Trademark Tianchen Origin Jinan, Shandong, China HS Code 8461409000 Production Capacity 30 Sets Per MonthProduct Description

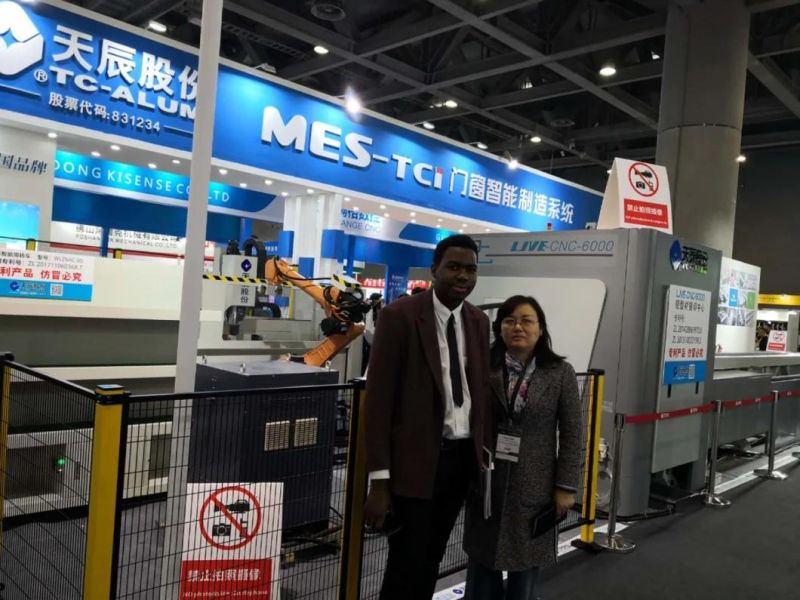

Aluminum Profile CNC Sawing Machine CenterModel LJVE-CNC-6000

Machine Main features:

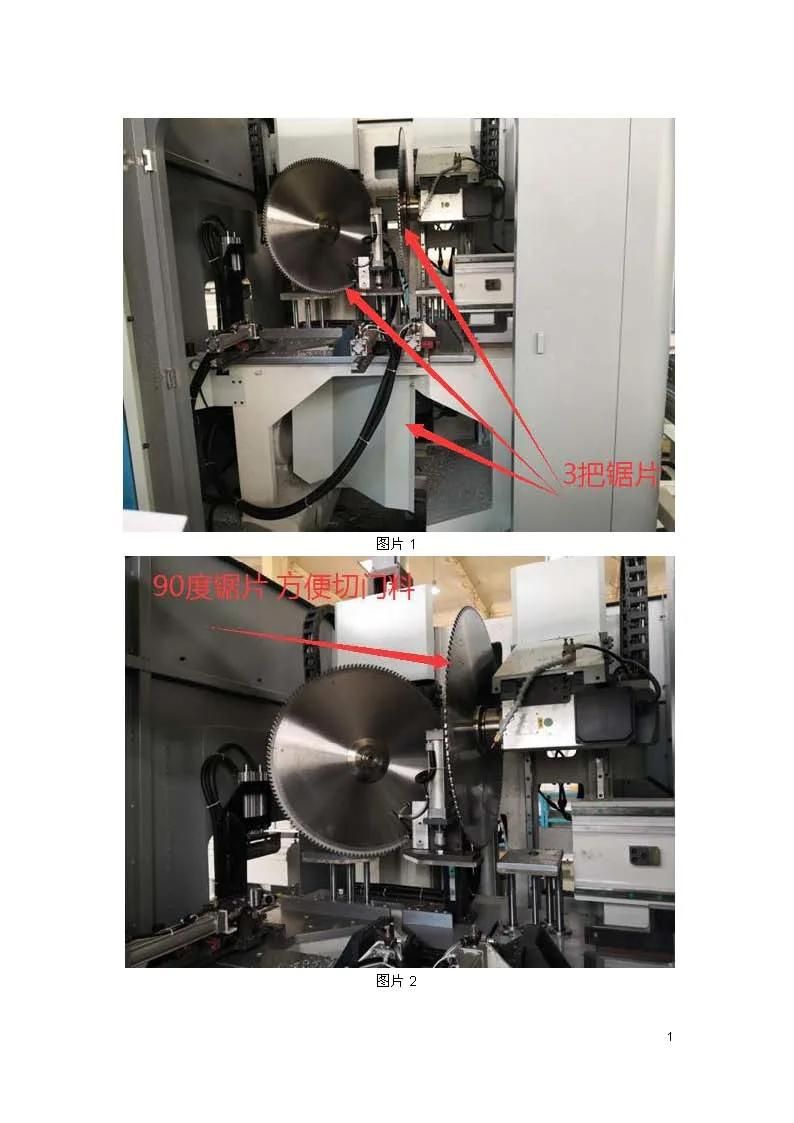

- It is used for high effective cutting aluminum profile at 45°or 90°.

- The auto worktable continuous feeding and clamping profile.

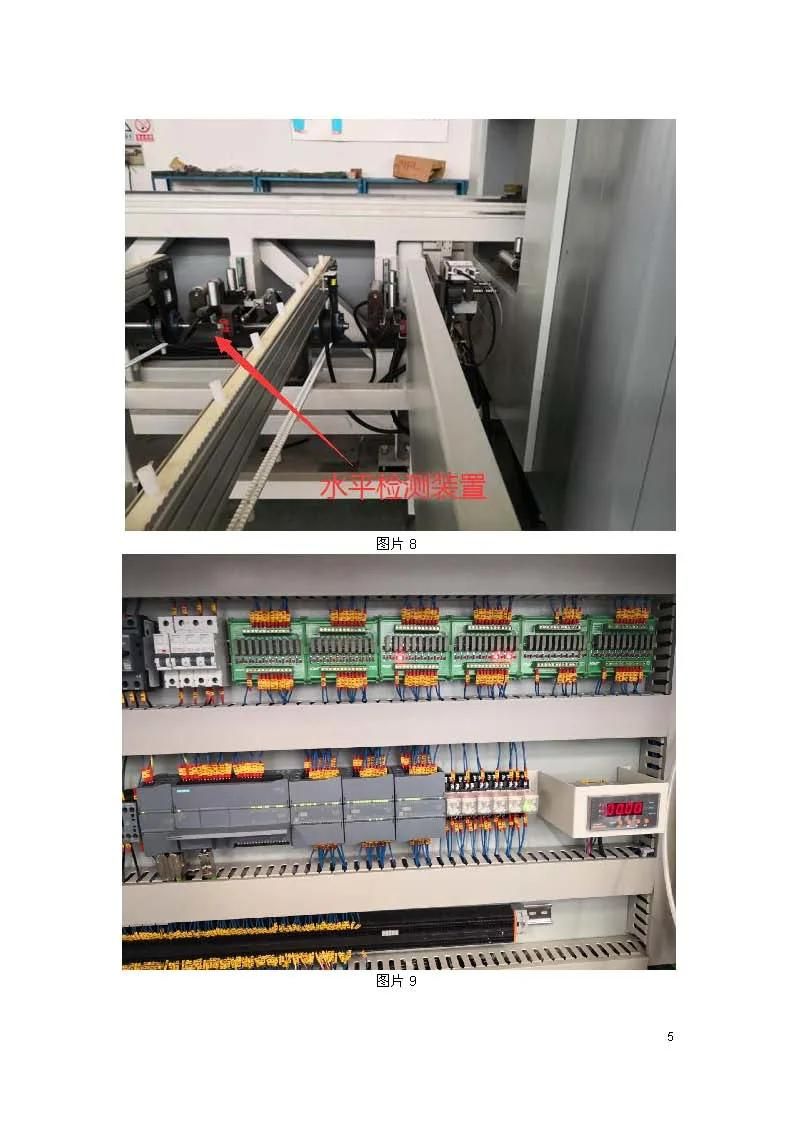

- It adopts high precision straight guide rail pair to ensure stability and reliable operation.

- Load mechanical arm adopts Siemens servo drive can reach to three axis (X, Y, Z) auto control. Imported high precision gear rack drive to ensure reliable feeding.

- Blade connected with imported motor. Cut smooth, steady and high precision.

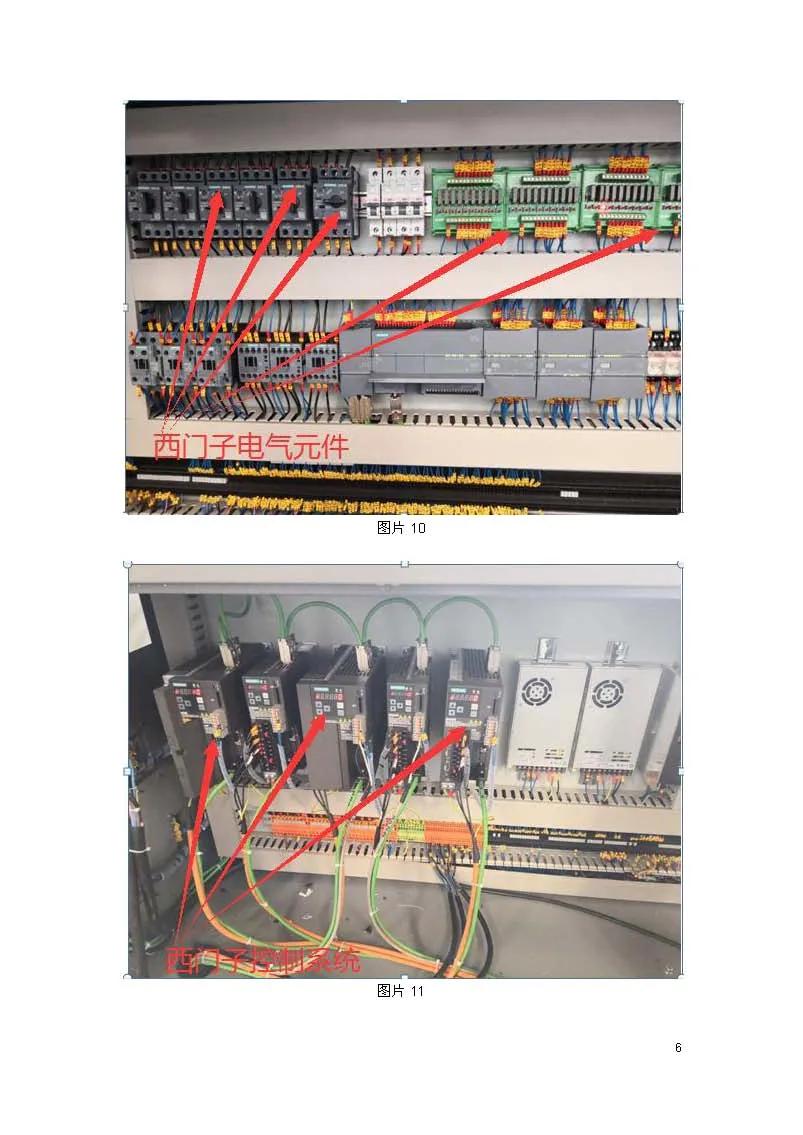

- Siemens control system makes machine working steady and reliable.

- It can complete the 45°cutting through up and down saw blade respectively cutting, high cutting precision, which can avoid partial breakage of profile.

- It can continuously complete profile ±45° or 90° cutting, high processing efficiency.

- Unload mechanical arm adopts servo driver, which can realize fast unloading, positioning function and be able to reach the auto output of the shortest profile 260mm.

- Roller linear guide pair and ball screw equipped with auto lubrication system, improve the precision and service life.

- Hinge type constantly conveys scrap and aluminum scrap to the outside.

- The totally enclosed safety cover to ensure the personal security.

- Option: Profile lifting platform to achieve the single person feeding operation

- Option: Bar code printer for E-works.

☆ Cutting Saw motor power: 3×3.0 kW

☆ Machine's total power: 18kW

☆ Input Power supply: 380V 50Hz

☆ Work pressure: 0.6~0.8MPa

☆ Air Consumption: 150L/min

☆ ±45°Sawing blade size: Ф550×Ф30×4.4×120T

☆ 90°Sawing blade size: Ф600×Ф30×4.4×120T

☆ Aluminum profile height: 30~140 mm

☆ Aluminum profile width: 30~100 mm

☆ Cutting Length: 260~6000 mm

☆ Cutting angle tolerance: ±5′

☆ Cutting length tolerance: ±0.15mm

☆ Repeating location tolerance: ±0.05mm

☆ Overall size (L*W*H): 14000×5000×2500 mm

☆ Net Weight: About 7000 kg

Main Outsourced Components List:

| Item | Brand name |

| Control System | Siemens |

| Servo Motor | Siemens |

| Air Cylinder | SMC |

| Damping Cylinder | SMC |

| Guide Rail | HIWIN |

| Ball Screw | PMI |

| Cutting Motor | Shenyi |

| Rack | YYC |

| Infeeding material Reduction Box | APEX |

| Output material Reduction Box | NEWSTART |

| Sawing Blade | Wagen (Japan) |

Our Service

Pre-sale service

Free contact for the most suitable machine

Free professional design for each customer especially.

After sale service

24 hours technical support by Phone, Email or Skype

1years warranty period

Our engineer is available to travel aboard, help the installation, maintenance and training client's machine's operator.

Payment

L/C, 30% deposit by T/T,70% spare payment L/C.

T/T, 30% deposit by T/T,70% spare payment before shipment.

Alibaba trade assurance, which protects your money in safe and ensure our machine's quality.

FAQ:

1. What's the productivity of this Automatic Cutting Saw Center?

Approximately this machine's work efficiency is 4 times of one set of Double head cutting saw. In average within one shift (8 hours) it can cut 2400 pieces of finished profile.

2. What you can do if my machines have problems?

1) We can send you free components to you if your machines are in guarantee time.

2) We can assign our engineers to repair your machines

3.Do you provide machine operation training?

Yes. We can send professional engineers to the working site for machine's installation, commissioning, and operation training.

All of our engineers have passport.

4. Which machine model shall I choose when I purchase from you?

We have both high-end machines and normal machines. Please inform us your estimated production capacity (how many windows you plan to produce per year) and your budget plan, we will recommend our machine models best for your request.

5. If I make Aluminum window and door, how many basic machines shall I have?

1).Double head cutting saw

2).Copy router milling machine

3).End milling machine

4).Automatic Corner connector cutting saw

5).Single head Corner crimping machine