PLC Control High Quality Tube Making Production Line

Zhangjiagang City Zhangyun Machinery Manufacturing Co., Ltd.- Pipe Material:Carbon Steel

- Condition:New

- Customized:Customized

- Theory:Inverter

- Application:Industry, Decoration

- Type:Pipe Welding Machine

Base Info

- Model NO.:ZY-HF165

- Color:as Customers′ Requirements

- Pipe Diameter:50-165mm

- Pipe Thickness:2.0-6.0mm

- Max.Speed:50m,Min

- Solid State High Frequency:500kw

- Cutting Length:4-10m

- Cutting:Flying Saw

- Transport Package:Rainproof Packaging

- Trademark:zhangyun machinery

- Origin:Zhangjiagang City

- HS Code:8515219000

- Production Capacity:10set,Month

Description

Basic Info.

Model NO. ZY-HF165 Color as Customers′ Requirements Pipe Diameter 50-165mm Pipe Thickness 2.0-6.0mm Max.Speed 50m/Min Solid State High Frequency 500kw Cutting Length 4-10m Cutting Flying Saw Transport Package Rainproof Packaging Trademark zhangyun machinery Origin Zhangjiagang City HS Code 8515219000 Production Capacity 10set/MonthProduct Description

PLC Control High Quality Tube Making Production LineHigh frequency welding machine is a strip as raw material, after uncoiling, molding, high frequency welding, sizing, straightening, cutting off a series of pipe forming process to produce complete sets of equipment or a variety of circular steel tube steel pipe line.

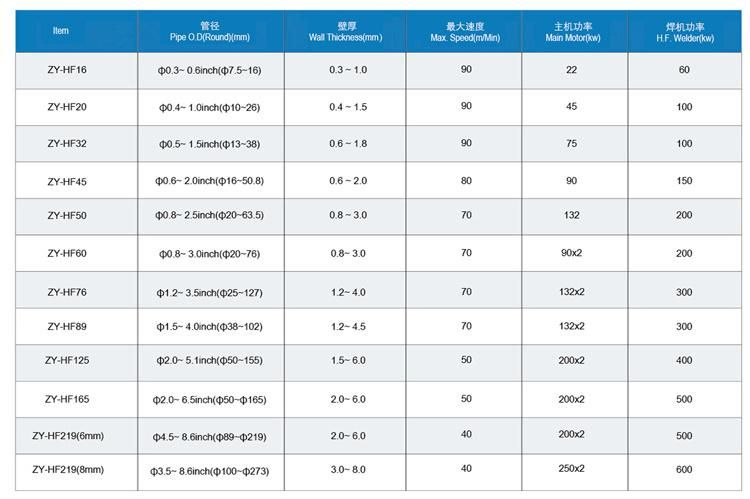

Main Specifications:

| Pipe Diameter | Φ50~Φ165mm |

| Wall Thickness | 2.0~ 6.0mm |

| Pipe Length | 4 ~ 10m |

| To-length Accuracy | ±3 mm |

| Raw Material Conditions | carbon steel |

| Width of Strip | 150~ 520mm |

| Thickness of strip | 2.0~ 6.0mm |

| Inner Diameter of Coil | φ508mm |

| Outer Diameter of Coil | ≤1600mm |

| Weight of Coil | ≤8t |

FAQ

1.Q: Are you manufacturer or trading company?

A: We are manufacture and trading company.

2.Q:What info you need before you make the proposal?

A:The pipe diameter and thickness range which you need or the profile drawings, material information, your special requirements.

3.Q: what is the MOQ?

A: One set

4.Q: Do you provide installing and debugging overseas?

A: Overseas machine install and worker training services are optional.

5.Q: Can you make the machine according to my design or prototype?

A: Yes, we have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

6.Q: How does your factory do regarding quality control?

A :There is no tolerance regarding quality control. Quality control complies with ISO 9001.every machine has to past testing running before it's packed for shipment.

7.Q: How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference

2) We welcome you visit us and test machine by yourself in our factory.

8.Q: What about our after-sale service?

A: we provide technical support on line as well as overseas services by skillful technicians.

9.Q: What should I do if I just start a new business?

A:Contact us immediately ,we provide free consultant pre-sales service.Also we can help you to solve the material(steel coil)purchase,worker train,international market price.

10. Q:Can I visit you factory to check machines on-site ? What Should I bring when I visit your factory?

A: We are manufacturer, and we welcome customers to visit our factory. For special product design and develop, we request you bring a piece of testing material, you can test on our machines on-site.