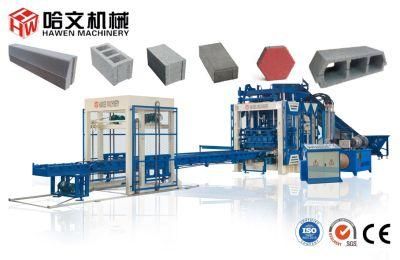

Fully Automatic Concrete India Flyash Brick Making Machine

Quanzhou Hawen Machinery Co., Ltd.- After-sales Service:Engineer Available to Abroad

- Warranty:One Year After Installation

- Certification:ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Vibration Molding

Base Info

- Model NO.:QT10-15

- M140 Hollow Block:14 PCS Per Drop

- Vibration:Servo Motor Vibration

- Pallet Size:1100-1150 X 950mm

- Rectangle Paver:36PCS Per Drop

- Weight of Main Machine:12ton

- Color of Machine:Blue &White or Grey&Yellow or Customized

- Paver Strength:30-50MPa

- Power of Servo Vibration Motor:12kwx2

- Matchable Mixer:MP750 or MP1000 Planetary Mixer

- Transport Package:Standard Ocean Packing

- Trademark:HAWEN

- Origin:China

- HS Code:8474809090

- Production Capacity:300 Sets, Year

Description

Production per Shift (8 Working Hours,with skilled workers)Hollow Block (400x200x200mm): 15,000~16,000 pcs Hollow Block (400x150x200mm): 17,000~19,000 pcs Stock brick(200x100x70mm):100,000-108,000 pcs "H"shape Paver (200x160x60mm): 28,800~38400pcs Zigzag shape Paver(225*112.5*60/80mm): 40,000~50,000pcs Rectangle Paver (200x100x60-80mm): 52,000~69,000pcs Vibrating Frequency: 2800-4500RPM Motors Power: 52.5 KW For Main forming machine parts only Machine Dimensions: 8800x3400x2800mm Pallet Size: 1100x950mm or 1200x900mm Gross Weight: About 12T Raw Materials: crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes Applied Products: concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. Applied Fields: widely used in buildings, road pavings, squares, gardens, landscaping, city constructions

Application of HWG-1000 Servo vibration block making plant on site

HWG-1000 block making machine,with Automatic Block Stacker,Automatic Pallet provider, MP1000 Planetary Concrete mixer on site

MP1000 Planetary Concrete mixer,using Conveyor belt to transfer the raw material to Concrete mixer

PL1600-4 Concrete Batching machine under the shed,separating from the workshop of main forming machine

Wet Concrete brick in curing yard under the shed

The wet concrete brick will be kept under the shed in the first day,then it will be transferred to stock yard for nature curing in the second day,

the Brick will be removed off and packed by off-line automatic cuber system if the automtic cuber system is available.

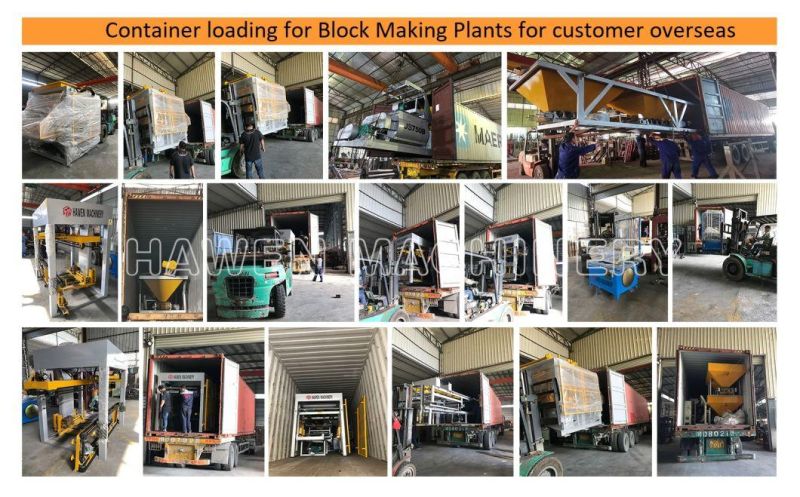

Container loading in workshp for customers overseas Company Profile:

Company Profile:

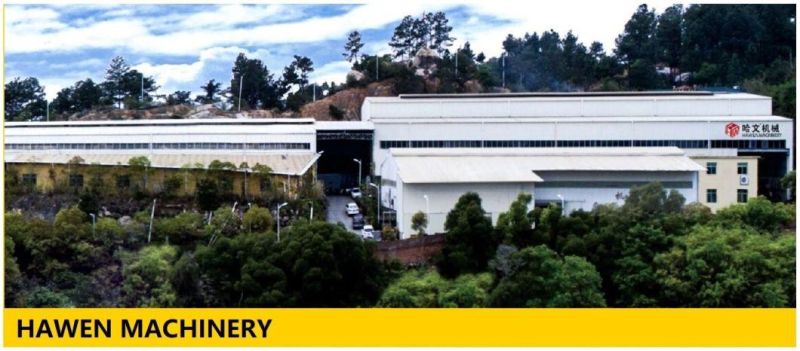

1. Manufacturer of Block making machine with more than 15 years experience

2. ISO Certified Company

Factory workshop overview

FAQ

1. How many square meters required to set up a block factory?

Answer:Generally,the whole factory requires 5000 square meters, including the recommended workshop to cover the equipments at 500 square meters,equipments are suggested to keep under the shed.

2.What kind of material can be used to produce concrete block?

Answer:Crushed stone(Max.10mm),sand and Cement as raw material, coal fly ash, cinder, slag,gangue, gravel, and other industrial wastes.And if customer makes the top colored paving stone,then the face material of fine sand and white cement and pigmen are required.

3.Can I get the warranty for the machine?

Answer:The warranty for the machine is one year after installation or 15 months after shipment,whichever comes first.Spare parts will be sent to customers for free of charge during the warranty period. Warranty does not cover the wearing parts, in cases of incorrect handling, improper user, insufficient maintenance, unauthorized service or modifications to the machine, normal wear .

4.What is the delivery time?

Answer:The delivery time is 30-40 days upon receiving the down payment and mould drawing approval from customer.

5. What about your payment terms?

Answer:T/T and L/C are acceptable.

Generally,it requested to pay 30% as depoist by T/T before production, and the balance to be paid by T/T or Irrevocable,Confirmed LC at sight before shipment.

6.How to prepare the foundation for the equipments?

Answer:The foundation drawing for the whole plant will be provided within 07 days after the order confirmed,customer could prepare the foundation construction according to the drawing provided.

7.How about the installation & commissioning ?

Answer:After the equipments arrive customer's site,and the preparation for the foundation,water & electricity are ready,we will send 1 of our technician for the installation & commissioning,the technician will train customer's staff for the operation and maintenance of equipment.

8.How about the installation cost?

Answer:We will send our technician for the installation,customer should responsiblefor all the expense and the allowance of our technician.

9.Are the machine be tested in your factory before shipment?

Answer:Yes all of our machines will be tested in our workshop before container loading.You are warmly welcome to do the inspection before shipment.

10.Can I visit your factory before placing the order and where is your factory ?

Answer:You are warmly welcome to visit our factory any time.Our factory located in Quanzhou City,Fujian Province.

The nearest airport to our factory is Jinjiang airport,which is 30 minutes to our factory by car.

How to come to your city?

Answer:You could take the international flight to Guangzhou airport first,then take the domestic flight from Guangzhou airport to Jinjiang airport,we will pick you up from Jinjiang Airport.

Or take the high speed train From Guangzhou South to Quanzhou train station.

Trust us with your project, we will provide the Optimal Concrete Products Making Solution for you all the time.

Welcome to contact our sales team:

Sales line: +86 18959896890

German Technology Automatic Concrete Block Making Machine Equipment

Hawen block making machines are for the manufacture of concrete bricks, blocks and paving. The machines are manufactured to heavy-duty standards to ensure long life, high performance and the manufacture of quality products.

Application of HWG-1000 Servo vibration block making plant on site

HWG-1000 block making machine,with Automatic Block Stacker,Automatic Pallet provider, MP1000 Planetary Concrete mixer on site

MP1000 Planetary Concrete mixer,using Conveyor belt to transfer the raw material to Concrete mixer

PL1600-4 Concrete Batching machine under the shed,separating from the workshop of main forming machine

Wet Concrete brick in curing yard under the shed

The wet concrete brick will be kept under the shed in the first day,then it will be transferred to stock yard for nature curing in the second day,

the Brick will be removed off and packed by off-line automatic cuber system if the automtic cuber system is available.

Container loading in workshp for customers overseas

Company Profile:

Company Profile:1. Manufacturer of Block making machine with more than 15 years experience

2. ISO Certified Company

Factory workshop overview

FAQ

1. How many square meters required to set up a block factory?

Answer:Generally,the whole factory requires 5000 square meters, including the recommended workshop to cover the equipments at 500 square meters,equipments are suggested to keep under the shed.

2.What kind of material can be used to produce concrete block?

Answer:Crushed stone(Max.10mm),sand and Cement as raw material, coal fly ash, cinder, slag,gangue, gravel, and other industrial wastes.And if customer makes the top colored paving stone,then the face material of fine sand and white cement and pigmen are required.

3.Can I get the warranty for the machine?

Answer:The warranty for the machine is one year after installation or 15 months after shipment,whichever comes first.Spare parts will be sent to customers for free of charge during the warranty period. Warranty does not cover the wearing parts, in cases of incorrect handling, improper user, insufficient maintenance, unauthorized service or modifications to the machine, normal wear .

4.What is the delivery time?

Answer:The delivery time is 30-40 days upon receiving the down payment and mould drawing approval from customer.

5. What about your payment terms?

Answer:T/T and L/C are acceptable.

Generally,it requested to pay 30% as depoist by T/T before production, and the balance to be paid by T/T or Irrevocable,Confirmed LC at sight before shipment.

6.How to prepare the foundation for the equipments?

Answer:The foundation drawing for the whole plant will be provided within 07 days after the order confirmed,customer could prepare the foundation construction according to the drawing provided.

7.How about the installation & commissioning ?

Answer:After the equipments arrive customer's site,and the preparation for the foundation,water & electricity are ready,we will send 1 of our technician for the installation & commissioning,the technician will train customer's staff for the operation and maintenance of equipment.

8.How about the installation cost?

Answer:We will send our technician for the installation,customer should responsiblefor all the expense and the allowance of our technician.

9.Are the machine be tested in your factory before shipment?

Answer:Yes all of our machines will be tested in our workshop before container loading.You are warmly welcome to do the inspection before shipment.

10.Can I visit your factory before placing the order and where is your factory ?

Answer:You are warmly welcome to visit our factory any time.Our factory located in Quanzhou City,Fujian Province.

The nearest airport to our factory is Jinjiang airport,which is 30 minutes to our factory by car.

How to come to your city?

Answer:You could take the international flight to Guangzhou airport first,then take the domestic flight from Guangzhou airport to Jinjiang airport,we will pick you up from Jinjiang Airport.

Or take the high speed train From Guangzhou South to Quanzhou train station.

Trust us with your project, we will provide the Optimal Concrete Products Making Solution for you all the time.

Welcome to contact our sales team:

Sales line: +86 18959896890

German Technology Automatic Concrete Block Making Machine Equipment

Hawen block making machines are for the manufacture of concrete bricks, blocks and paving. The machines are manufactured to heavy-duty standards to ensure long life, high performance and the manufacture of quality products.