Corrugated Sheet Barrel Corrugation Sheet Forming Machine

Cangzhou Hener International Trade Co., Ltd.- After-sales Service:Online Support, Free Spare Parts

- Warranty:12 Months

- Tile Type:Colored Steel

- Certification:CE, ISO

- Condition:New

- Customized:Customized

Base Info

- Usage:Roof, Wall

- Transmission Method:Gearbox Drive

- Total Power:11kw

- Material Thickness:0.125-0.6mm

- Flat Rollers Diameter:400mm

- Forming Roller Diameter:450mm

- Processing Width of Raw Material:750mm-1200mm

- Machine Speed:10-15 Pieces Sheets,Minute

- Machine Frame Thickness:100mm Thickness

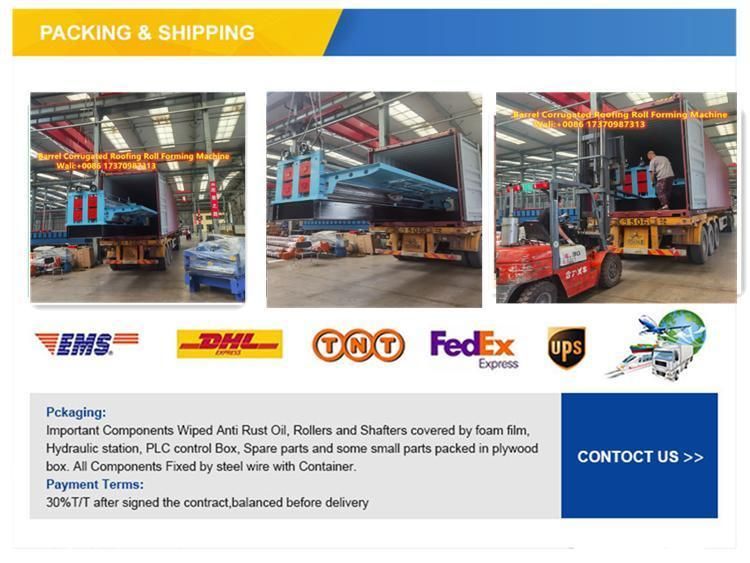

- Transport Package:in Nude, with Waterproof Cloth and Stow-Wood

- Specification:4300mm*2000mm*1500mm

- Origin:China

- HS Code:84552210

- Production Capacity:30sets,Month

Description

NO.

Description

Quantity (set)

1

Transport material platform

1

2

Start stop button

1

3

Flat roller

2

4

Forming roller

2

5

Flat roll gear

2

6

Transmission shaft

2

7

Reducer

1

8

Distribution box

1

No

Item

Parameter

Note

1

Raw material

PPGI/G550

2

Material Thickness

0.125-0.6mm

At the same time, theaccumulationsheets' thickness cannot exceed 0.6mm

3

Flat rollers diameter

340mm

The rollers has 2 pieces

4

Forming roller diameter

390mm

The rollers has 2pieces (welded)

5

Processing width of raw material

750mm-1200mm

6

Machine speed

10-15 pieces sheets/minute

7

Machine frame thickness

100mm thickness

steel plate welding

8

Main motor power

If cut 3m length: 11kw

If cut 4/5m length: 15kw

Shanghai LiChao Brand

9

Transmission method

Gear chain drive

stepless frequency conversion speed regulation

10

Voltage

11

Production capacity

2-4 tons/h

12

Machine sizes

If cut 3m length : W2.25*L4.5m

If cut 4m length: W2.3*L5.9m

If cut 5m length: W2.35*L7.5m

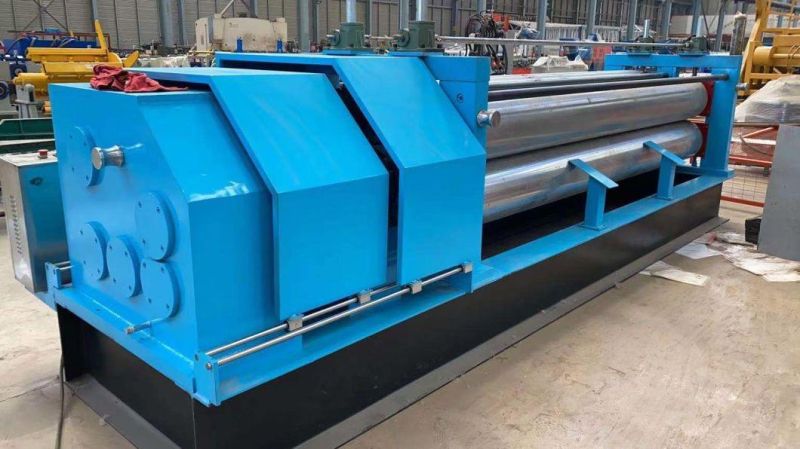

Here are some poctures of Barrel style round wave sheet roll forming machine for your reference:

Product Features

1. More efficient and accurate execution of production orders;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to

ensure that customers can get qualified products at the same time, it can avoid the scratch of the color

steel surface paint, and increase the service life of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.

Product packaging

Our Team And Cooperation Cases

Certification

Company Profile

Why choose Us?

Why choose Us?- We have sold more than 3000 sets roll forming machines to many countries around the world.

- We have hundreds of models about all kinds of roll forming machine for your reference, you not need worry if you don't have a profile drawing.We can recommond you some classical models that is common in your country.

- When designing the machine, our considerate service will estimate and avoid the problem that may happen.

- One set machine can provide many solutions with different price level.But they are all the cost-effective.

- We attach importance to many details. Every machine part quality is higher than our competitors in same price level.