Fire Bricks Oven in Whole Brick Factory

Xi'an Brictec Engineering Co., Ltd.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Brick Making Machinery

- Condition:New

- Exported:25 Countries

Base Info

- Model NO.:YL

- Agent:Nepal, India, Bangladesh, Egypt, Venezuela

- Function:Energy Saving

- Method:Vacuum Extruder

- Raw Material:Clay. Mud Soil

- Material:All Steel

- Guarantee:1 Year

- After-Sales Service:Lifetime

- Automatic:Yes

- Transport Package:Container

- Specification:3.6 meter x 130 meter

- Trademark:BRICTEC

- Origin:China

- HS Code:8474

- Production Capacity:45, 000, 000 PCS Bricks

Description

Basic Info.

Model NO. YL Agent Nepal, India, Bangladesh, Egypt, Venezuela Function Energy Saving Method Vacuum Extruder Raw Material Clay. Mud Soil Material All Steel Guarantee 1 Year After-Sales Service Lifetime Automatic Yes Transport Package Container Specification 3.6 meter x 130 meter Trademark BRICTEC Origin China HS Code 8474 Production Capacity 45, 000, 000 PCS BricksProduct Description

TUNNEL KILNTunnel kiln is an advanced and automatic technology in brick making industry.

The advantage as following:

1. Continuous kiln

A tunnel kiln is a type of continuous kiln that is typically open on both ends and heated centrally. Building materials, such as bricks, may be passed through the device in an uninterrupted fashion, allowing large volumes to be processed without shutting off the kiln between batches.

2. Fuel

A number of different methods can be used to heat tunnel kilns. Typical heat sources include coal, gas, and other fuel.

3. Automatic Computer-controlled

Tunnel Kilns are computer-controlled, continuously operating car-bottom kilns. Computer technology allows kiln car movement through the kiln to be controlled for changes in firing curves and firing temperatures. Automatic controls can be programmed to make firing changes for differences in product size and color.

4. High capacity

Ferry Pushers move the train of cars non-stop at a predetermined rate. This method is ideal for all ceramic industries requiring high volume production and/or a continuous production process.

If you are interested in tunnel kiln, you have to consider two conditions:

1. The fuel can be coal, gas, coal-gas, oil etc.

2. The investment budget will be depend on the automatic degree (project design and feasibility study, investment pay-back period)

| Tunnel kiln | Capacity | Equipment of kiln | Production days in a year |

| 2.5 meters width | 15-20million pcs annual | Kiln cart,hydraulic ferry pusher,stepper,outlet pulling machine,air blowers,railways | 330days |

| 3.3 meters width | 20-25million pcs annual | Kiln cart,hydraulic ferry pusher,stepper,outlet pulling machine,air blowers,railways | 330days |

| 3.4 meters width | 20-28million pcs annual | Kiln cart,hydraulic ferry pusher,stepper,outlet pulling machine,air blowers,railways | 330days |

| 4.6 meters width | 25-38 million pcs annual | Kiln cart,hydraulic ferry pusher,stepper,outlet pulling machine,air blowers,railways | 330days |

| 6.9 meters width | 35-40 million pcs annual | Kiln cart,hydraulic ferry pusher,stepper,outlet pulling machine,air blowers,railways | 330days |

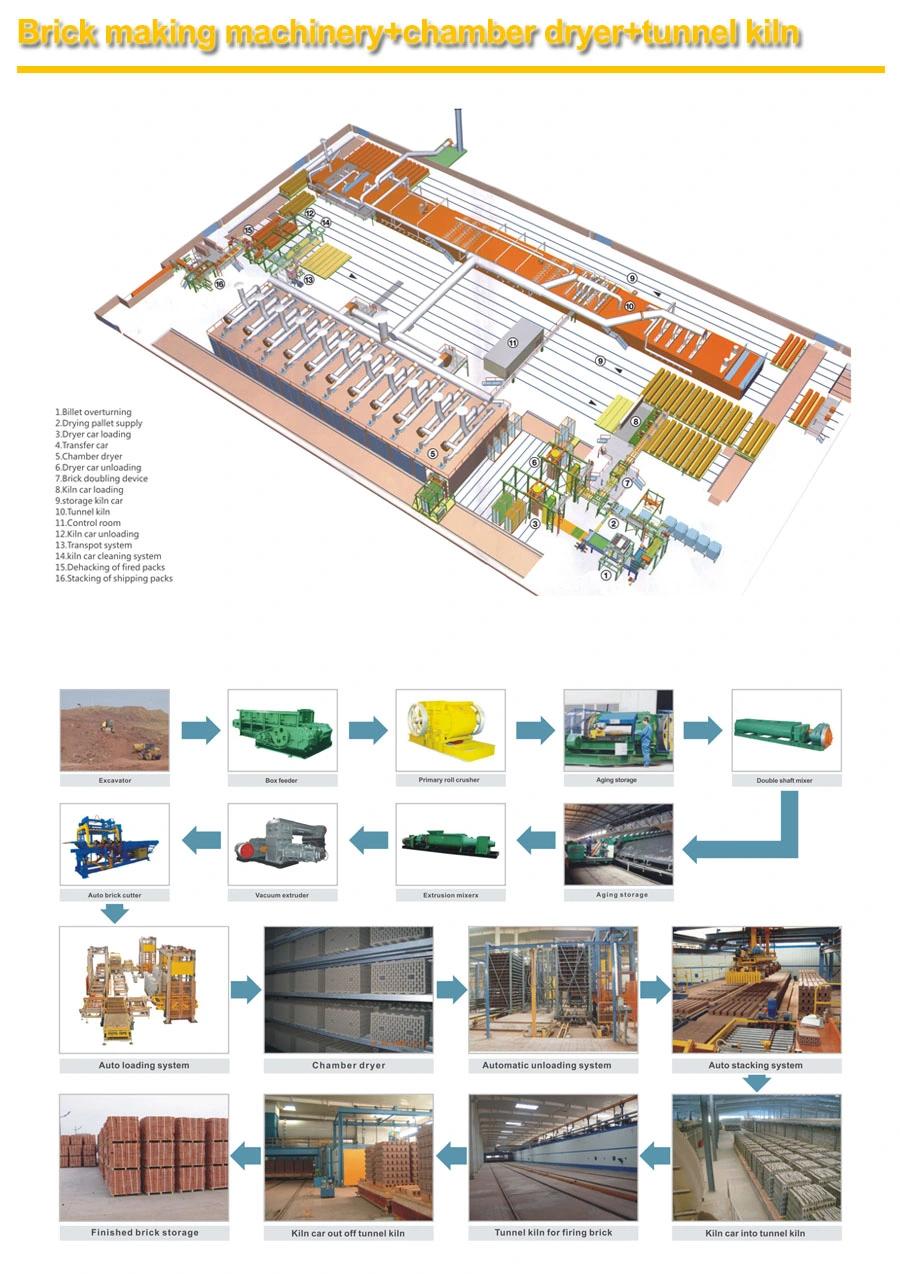

Brick Making and Forming Production line Flow Chart

Raw material preparation----Brick forming & cutting---Dryer&firing ---Brick transport and Packing

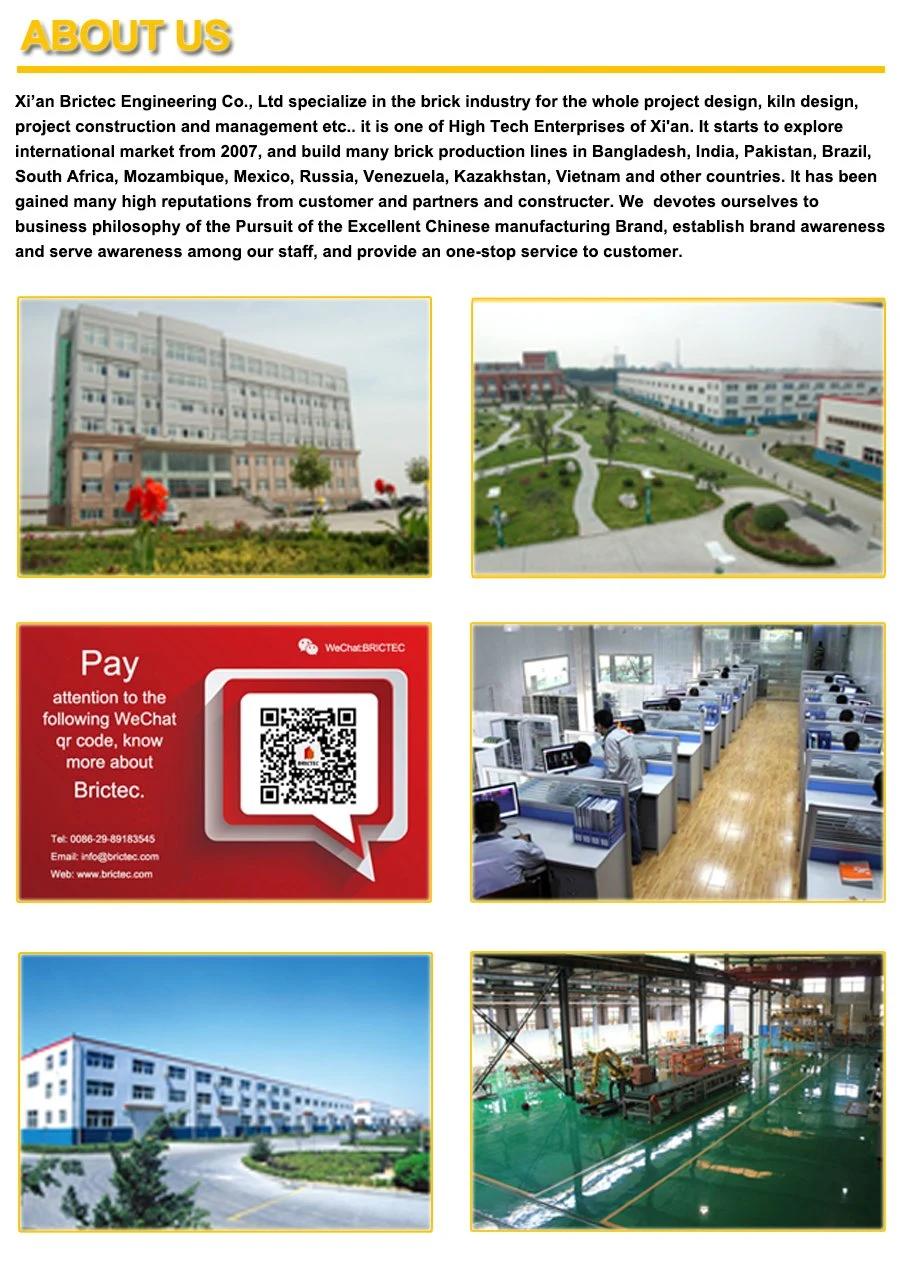

Our Team & Company information

We have professional team do the kiln construction, supervision, machinery installation, commissioning. It means we provide one-stop service and whole responsibility, if you take the services from many different companies, the Mutual shirk responsibility is happened in most of the failure brick factory.