2016 High Quality New Type Rotary Kiln in China

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Certification:ISO

- Product Name:Rotary Kiln

- Installation:Under Technical Guidance

- Color:Clinet′s Request

- Manufactory:Professional Producing Cement Plant

- Sealing Type:Sheet Steel Seal

Base Info

- Model NO.:Rotary Kiln

- Spare Parts:Life Long Time

- Quality:Chinese Standard

- Transport Package:Standard Packing for Rotary Kiln

- Specification:as the model of rotary kiln

- Trademark:HC

- Origin:China

- HS Code:8417100000

- Production Capacity:80set,Month

Description

Basic Info.

Model NO. Rotary Kiln Spare Parts Life Long Time Quality Chinese Standard Transport Package Standard Packing for Rotary Kiln Specification as the model of rotary kiln Trademark HC Origin China HS Code 8417100000 Production Capacity 80set/MonthProduct Description

Introduction of rotary kilnRotary dryer is a type of drying machine used to reduce the moisture of raw material, it is widely applied in building materials, cement, metallurgy, chemicals, coal, fertilizer, sawdust industrials. it can accept almost all kinds of materials and can quick drying the materials. It is easy to operate and has large capacity. that is why this machine is so welcomed in every field.

Application of rotary kiln

Rotary kiln dryer for sale is widely used in building materials, metallurgy, chemicals, coal, fertilizer industries to dry the materials with certain humidity or guanularity. The rotary dryer can be used for the drying of many rotary kiln dryer for sale materials,such as the coal slurry, the metal powder the building industry. and many other industry. Generally speaking it can dry the material from 30-40% humidity to 1-5% humidity. According to the different characteristic of the material, the model of the rotary dryer it use will be a little bit different.

Working principle of rotary kiln

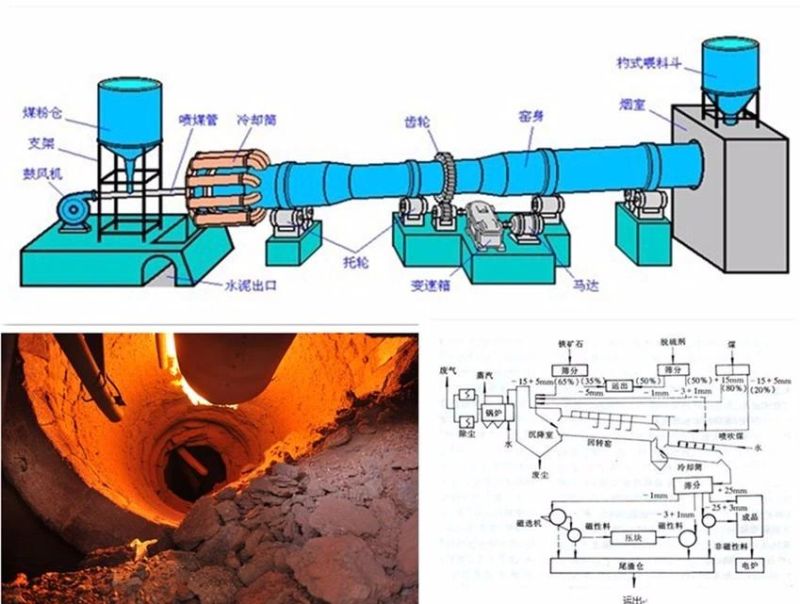

The wet materials are conveyed to the hopper through the belt conveyor or bucket elevator, and then enter into the feed end through the hopper charger and the feeding pipe in sequence. The inclination of the feeding pipe must be greater than the natural inclination of materials in order to make the materials flow into the dryer smoothly. The dryer cylinder with slight inclination with the horizontal line. The materials enter from the higher end, and the heat carrier enters from the lower ender; the two contact each other from opposite directions, but there are also circumstances that the heat carrier flows into the dryer body together with the material.

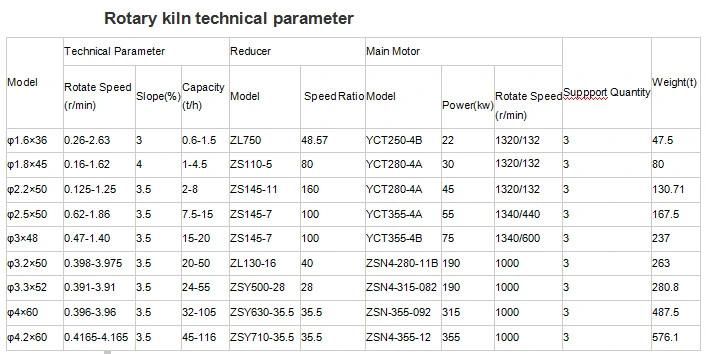

Technical parameters of rotary kiln