Double Glazing Machinery Silicone Sealant Extruding Machine

JINAN MAG GROUP CO., LTD.- Condition:New

- Certification:CE

- Automatic Grade:Automatic

- CNC or Not:not CNC

- Voltage:No Need Electricity

- Application:Coating The Silicone Sealant on Ig

Base Info

- Model NO.:ST01

- Max Rate:6:1-14:1

- Base Bucket:200L

- Curative Agent Bucket:20L

- Max Buytl Squeezing Pressure:20MPa

- Air Supply Pressure:0.5-0.8MPa

- Weight:600kg

- Transport Package:by Non-Fumagation Plywoodcase

- Specification:Machine size: 1200x1100x2500mm

- Trademark:MAG

- Origin:Jinan

- HS Code:84752990

- Production Capacity:100 Sets,Year

Description

Basic Info.

Model NO. ST01 Max Rate 6:1-14:1 Base Bucket 200L Curative Agent Bucket 20L Max Buytl Squeezing Pressure 20MPa Air Supply Pressure 0.5-0.8MPa Weight 600kg Transport Package by Non-Fumagation Plywoodcase Specification Machine size: 1200x1100x2500mm Trademark MAG Origin Jinan HS Code 84752990 Production Capacity 100 Sets/YearProduct Description

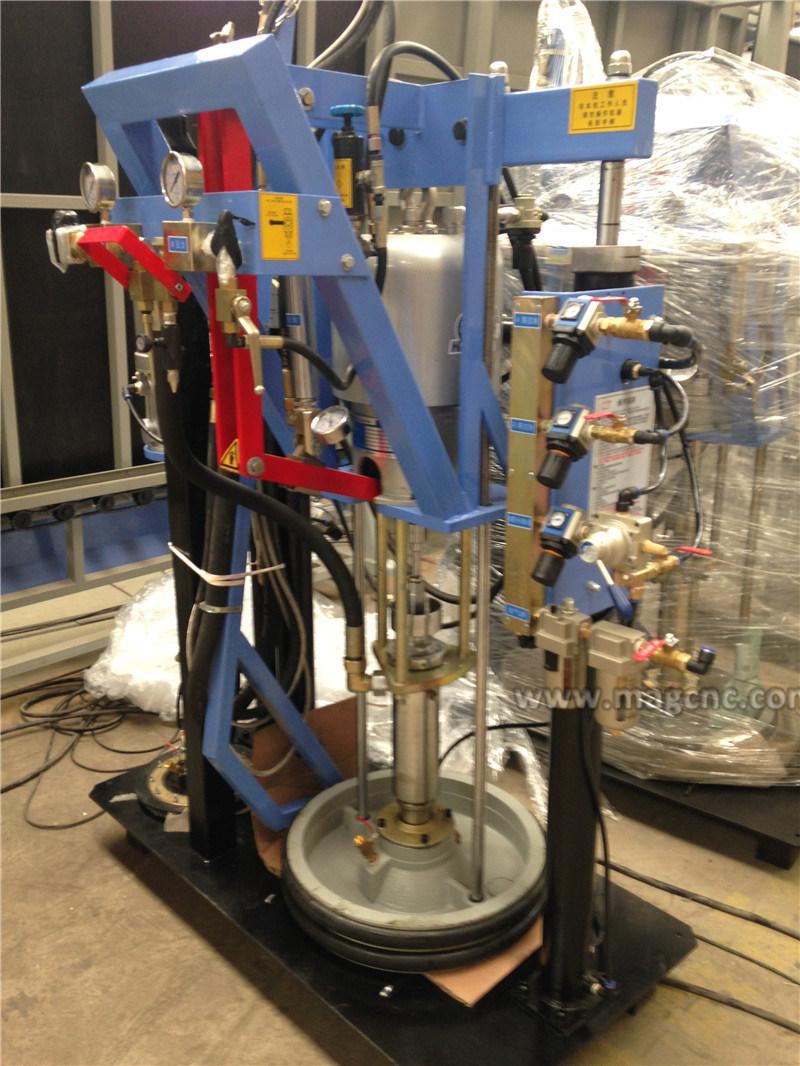

ST01 Silicone Extruder (Two Air Cylinder)

Features:

1-This extruder is the special machine for spreading double-component sealant.

2-It is full pneumatic type and do not need electric supply, can be easy to move and operation in the building site.

3-Easy operation, easy maintenance, stable working, high efficiency, It can suit the request of insulating glass and glass curtain wall batch production.

4-The main parts is from world known brand, the key mechanism parts is high strength stainless steel after heat treatment process from refining, thus to assure the machine good quality.

5-Take stainless straight flow type mixer, with small resistance, big output quantity.

6-Main motor take double pneumatic controlling system, to make the machine low malfunction and more stable.

7-There is alarm system, when any of A, B is not available, it will alarm automatically to remind the

operator.

8-Rubber mixing system take hanging device, to decrease the labor intensity.

9-There are two seals for the B rubber, to decrease the leakage of B rubber pressure plate.

10-With 2 filters before high pressure system, to avoid the dust into high pressure system, to make sure for the machine stability.

11-Compared with the hydraulic type, this model is quick speed, low failure rate.

Technical parameters:

| Brand | MAG |

| Model | ST01 |

| Mixing Ratio | 6:1--14 :1 |

| Basic Component Bucket | 55 Gallon(200L) |

| Hardener Bucket | 5 Gallon(20L) |

| Max Air Consumption | 1.0m3/min |

| Sealant Air Pressure Rate | 50:1 |

| Max Squeezing Pressure | 29Mpa |

| Air Pressure | 0.5--0.8Mpa |

| Outside Dimension | 1100*950*1630mm |

| Weight | 650kg |

Machine photos:

Company information: