Curbstone Block Pressing Machine Best Block Machine Manufacture

Linyi Raytone Machinery Imp&Exp Co., Ltd.- Warranty:One Year

- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydroforming

- Voltage:220V,380V

Base Info

- Model NO.:QT12-15

- Main Vibration Form:Platform Vibration

- Pallet Size:1300*900mm

- Cycle Time:15-20s

- Host Machine Matched Power:44kw

- Rated Pressure:21MPa

- After-Sales Service Provided:Engineers Available to Service

- Brick Raw Material:Concrete

- Transport Package:Suitable for Sea Transport

- Specification:9350*2520*2950mm

- Trademark:Raytone machinery

- Origin:Shandong, China (Mainland)

- HS Code:8474802000

- Production Capacity:50 Set,Sets Per Month

Description

Basic Info.

Model NO. QT12-15 Main Vibration Form Platform Vibration Pallet Size 1300*900mm Cycle Time 15-20s Host Machine Matched Power 44kw Rated Pressure 21MPa After-Sales Service Provided Engineers Available to Service Brick Raw Material Concrete Transport Package Suitable for Sea Transport Specification 9350*2520*2950mm Trademark Raytone machinery Origin Shandong, China (Mainland) HS Code 8474802000 Production Capacity 50 Set/Sets Per MonthProduct Description

QT12-15 AUTOMATIC BLOCK MACHINE INTRODUCTION1.QT12-15 Fully Automatic Block Making Machine Generally Description

QT12-15 Fully Automatic Block Making Machine is with advanced design and technology. It has the biggest block Productivity for now, the block machine is quipped with big power motors to give high pressure on the blocks, so strength blocks and bricks, so the block quality is excellent.

QT12-15 full automatic brick Machine productivity: 23040 pieces of 8 inch hollow blocks per day;

- QT12-15 Automatic Brick Machine line Basic requirements

| land area | 2500-6500 Square Meters | Water Consumption | 14.4 T/day |

| Workshop area | 200 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V; 50HZ/60HZ |

| Labors Quantity | 6 workers | Power Consumption | 125.2KW*8 Hours= 1001.6KWH; |

| Cement Consumption | 37.8 Tons per day | Sand consumption | 151.2 tons per day |

| Crushed stones consumption | 187.2 tons per day |

3.Detailed Introduction of each single machine from QT12-15 fully Automatic block making machine

(1) 100 Tons Cement Silo for QT12-15 Full automatic block making machine plant

| Capacity: | 100T | tank height | 9.6M |

| tank diameter | 3.0M | cone height | 2.5M |

| leg height | 2M | total Height | 15.1M |

(2) 8 meters Length cement screwing machine for QT12-15 full automatic block machine

Length : 8 Meters, Power: 11KW; the diameter: 219mm

or Length: 6 Meters, Power: 7.5KW; the diameter: 219mm

The cement screwing machine is used to screw the cement

from cement silo to the cement scale, which is installed on

the JS750 concrete mixer;

- cement scale for QT12-15 full automatic block machine

(4) PLD1200 three hopper batching machine for QT12-15 full automatic block machine

| Weighing Volume | 1.2CBM | Productivity | 60M3/H |

| Maximum weighing | 2000KG | Storing Volume | 2.2CBM*3 |

| Feeding height | 2800MM | Aggregate types | 3 types |

| Batching accurancy | ±2% | Belt conveying speed | 1.25m/s |

| power | 3kw*4 | Dimension: | 8830*2100*3300mm |

| Machine weight | 4000kg |

(5) 7 meters length fast belt conveying machine for QT12-15 full automatic block machine

Length: 7000mm; width: 500mm, power: 2.2KW; cycloidal needle wheel type motor;

(6)JS750 Concrete Mixer for QT12-15 automatic brick machine

| Charging Volume | 1200L | Discharging Volume | 750L |

| Aggregate Size: | ≤60/80mm | Capacity | 35 Cubic meters/hour |

| Working Circle | 60S | Mixing Speed | 35R/M |

| pump motor | 1.1kw | Mixing Blade | 2*8 |

| mixing motor | 30KW | Dimension | 4550*2250*2450mm |

| Machine weight | 5500kg |

one is with elevator hopper, the other one is without

elevator hopper, the JS750 concrete mixer without

elevator is using fast belt conveying machine to

feed raw materials into the mixer;

(7) Host QT12-15 Big Automatic Block Machine

<1> The main parameters of QT12-15 big Automatic block machine

| Dimension of host machine | 9400*3060*2980mm | water Consumption | 14T/day |

| Weight of the host machine | 12.5T | Voltage | customized |

| Moulding period | 12-20S | Total required machine power | 107.8 |

| pallet size | 1400*900*30mm | Diesel Genset capacity | 120KVA |

| Vibration force | 100KN | workshop area | 250-300 m2 |

| labour | 3 | Land Area | 2500-6500 m2 |

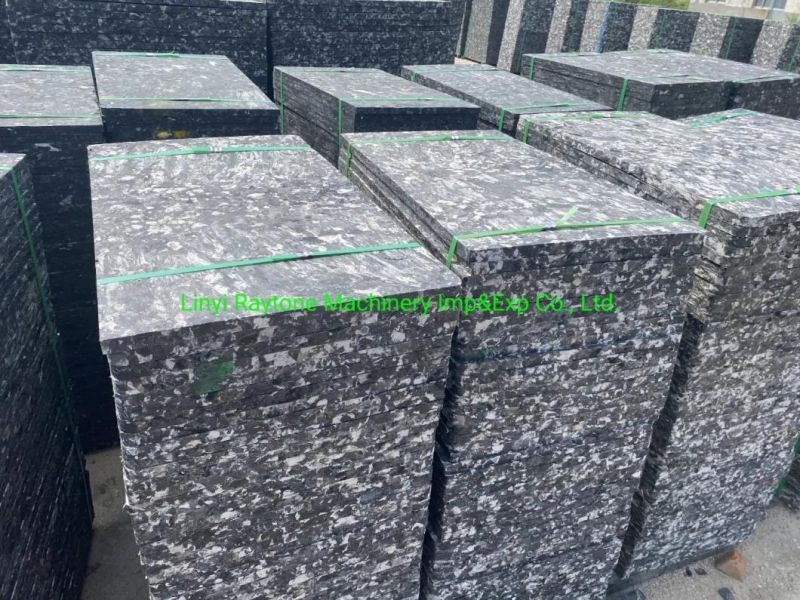

(8) GMT brick Pallets for QT12-15 automatic brick machine

The GMT block pallet is made from the leftovers of car inner roof decorations, seats and some adhesive etc. It is like PVC brick pallet , but better performance and cheap cost than PVC brick pallet, it is strong enough for block machine, life can be 6-8 years.

9.Why choose our block machine?

(1) For the steel raw materials , our block machine is buying from China standard big steel factory to guarantee the raw materials quality first.

(2) For the welding, our block machine manufacture workers are very experienced and skilled. They have many years work experience in brick machine making.

(3) For the PLC control panel, client can choose Germany Siemens brand, the hydraulic electromagnetic valves, our block machine provides standard Taiwan CLYCA brand, but client can choose Japan YUKEN brand for optional, also for the sensor, our block machine is using Japan Omron brand;

(4) our block machine is using high manganese steel for block moulds, and strictly via Linear cutting , carbonized and heat treatment procedures, to make sure the block mould is with enough hardness for long life.

(5) our block machine design is advanced by reasonable raw material distributing system, Synchronous mould lift structure and vibration system;

Welcome contact us if you are interested in our block making machine .