Low Price Concrete Cement Interlock Machine

Quanzhou Hawen Machinery Co., Ltd.- After-sales Service:Engineer Available to Abroad

- Warranty:One Year After Installation

- Certification:ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Vibration Molding

Base Info

- Model NO.:QT4

- Pallet Size:980X680mm

- After Sales Service:Engineer Available to Overseas

- Quad Cabro:16PCS Per Cycle

- Vibration:Motor Vibration

- Working Method:Automatic

- M140 Hollow Block:6PCS Per Cycle

- Size of Workshop Required:300 Square Meters

- 40X20X20cm Block:4PCS Per Cycle

- Working Plant in Kenya:in Nairobi,Kisumu City etc.

- Transport Package:Standard Ocean Packing

- Trademark:HAWEN

- Origin:China

- HS Code:8474809090

- Production Capacity:300 Sets, Year

Description

Production per Shift

(8 Working Hours):Hollow Block (400x200x200mm): 5,700~5,800 pcs Hollow Block (400x150x200mm): 8,600~8,700 pcs Fly Ash brick(230x110x75mm): 26,800pcs Interlocking paver (225*112.5*60/80mm): 20,000~26,800pcs Quad Paver (200x100x60-80mm): 23,000~30,000pcs

Processing equipment in the workshop

Application of QT4-15 Automatic Block,paver making machine on site

QT4-15 makes Rectangle Paver(Quad Cabro in Kenya ) with size 200x100x60mm at 16pcs/mould;

QT4-15 makes Rectangle Paver(Quad Cabro in Kenya ) with size 200x100x60mm at 16pcs/mould;

For making Interlocking paver (Zigzag paver) with the size at 225x112.5x60mm at 14pcs/mould.

For hollow block at 390x140x190mm, at 6pcs/mould.

For making Fly ash brick at 230x110x75mm,the capacity is 14pcs/cycle.

For making Fly ash brick at 230x110x75mm,the capacity is 14pcs/cycle.

Interlocking hollow block made by QT4-15 block making machine and its application on construction site.

Interlocking hollow block made by QT4-15 block making machine and its application on construction site.

Container loading in workshp for customers overseas

Block and Brick Sample

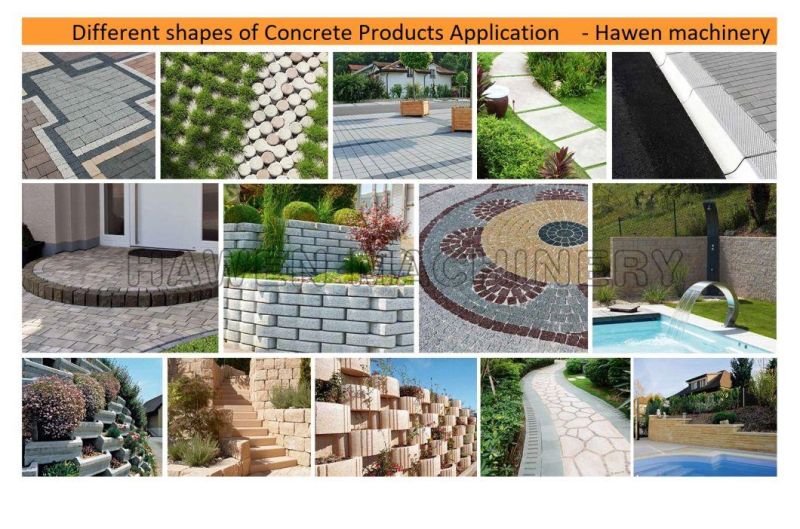

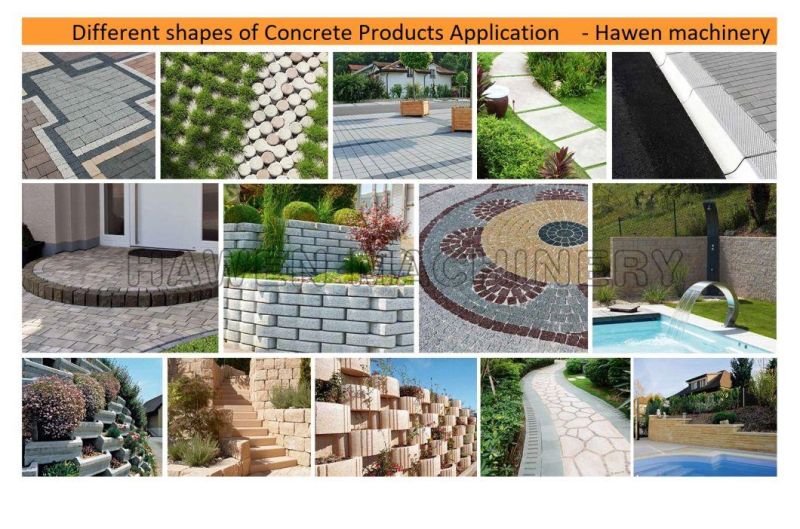

Application:

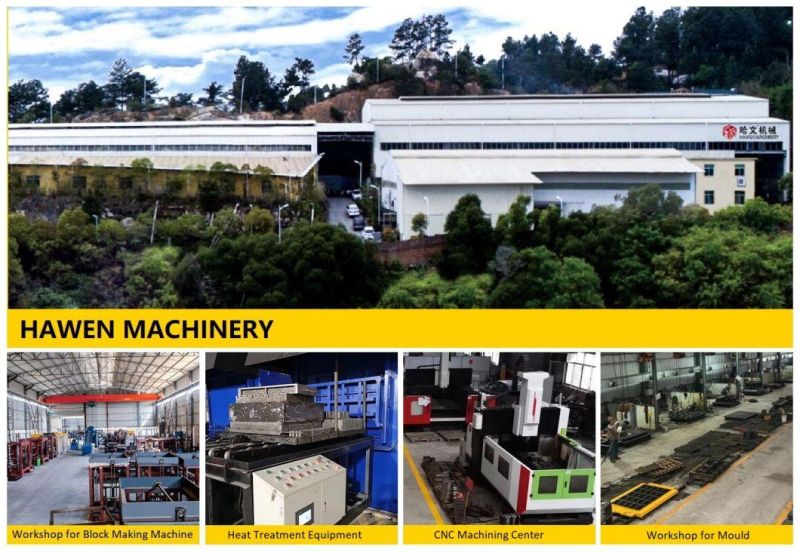

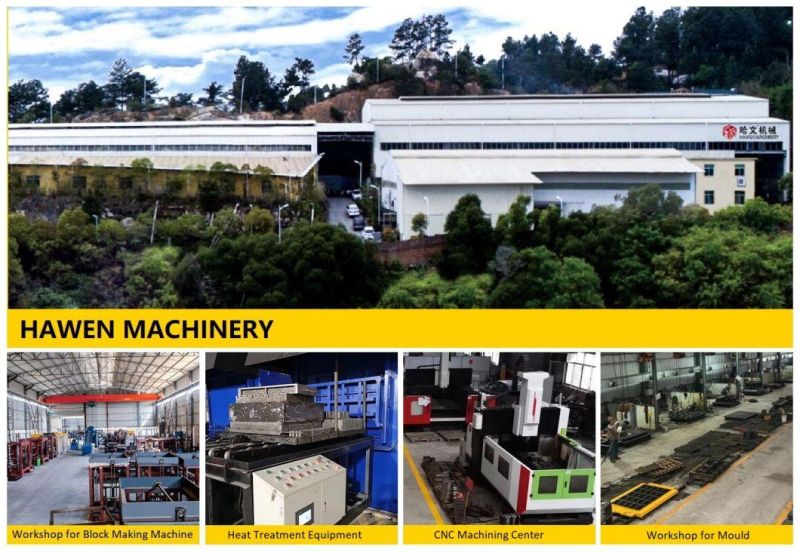

Company Information

Company Information

(1) Hawen block making machines are for the manufacture of concrete bricks, blocks and paving stone,with ISO9001:2015 Quality Management Certificate,all block and brick making machines are manufactured to ISO Certification specs with state-of-the art technology;

(2) The machines are manufactured to heavy-duty standards to ensure long life, high performance and the manufacture of quality products.

(3) Hawen block making equipments are for every aspect of concrete products solution,such as common masonry like block &brick,Paving stone ,curb stone,patio stone,segmental retailing wall products,fencing units,other landscape prodcts.

(4) We offer a large ranges of stationary machines with various capacities and various pallets size that will fullfill you needs with different investment budget;

(5) Moulds: Our moulds are innovative,versatile and capable of making high quality of concrete products.

Factory workshop

Our Service

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order

Send technicians to installation site for the guidance, equipment commissioning and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help.

FAQ

1. How many square meters required to set up a block factory?

Answer: Generally,the whole factory requires 2000-3000 square meters, including the recommended workshop to cover the equipments at 300-400 square meters,equipments are suggested to keep under the shed.

2. What kind of material can be used to produce concrete block?

Answer:Crushed stone(Max.10mm),sand and Cement as raw material, coal fly ash, cinder, slag,gangue, gravel, and other industrial wastes.And if customer makes the top colored paving stone,then the face material of fine sand and white cement and pigmen are required.

3. Can I get the warranty for the machine?

Answer:The warranty for the machine is one year after installation or 15 months after shipment,whichever comes first.Spare parts will be sent to customers for free of charge during the warranty period. Warranty does not cover the wearing parts, in cases of incorrect handling, improper user, insufficient maintenance, unauthorized service or modifications to the machine, normal wear .

4.What is the delivery time?

Answer:The delivery time is 30-40 days upon receiving the down payment and mould drawing approval from customer.

5. What about your payment terms?

Answer:T/T and L/C are acceptable.

Generally,it requested to pay 30% as depoist by T/T before production, and the balance to be paid by T/T or Irrevocable,Confirmed LC at sight before shipment.

6. How to prepare the foundation for the equipments?

Answer:The foundation drawing for the whole plant will be provided within 07 days after the order confirmed,customer could prepare the foundation construction according to the drawing provided.

7.How about the installation & commissioning ?

Answer: After the equipments arrive customer's site,and the preparation for the foundation,water & electricity are ready,we will send 1 of our technician for the installation & commissioning,the technician will train customer's staff for the operation and maintenance of equipment.

8. How about the installation cost?

Answer:We will send our technician for the installation,customer should responsiblefor all the expense and the allowance of our technician.

9. Are the machine be tested in your factory before shipment?

Answer:Yes all of our machines will be tested in our workshop before container loading.You are warmly welcome to do the inspection before shipment.

10.Can I visit your factory before placing the order and where is your factory ?You are Answer: Warmly welcome to visit our factory any time.Our factory located in Quanzhou City,Fujian Province.

The nearest airport to our factory is Jinjiang airport,which is 30 minutes to our factory by car.

How to come to your city?

You could take the international flight to Guangzhou airport first,then take the domestic flight from Guangzhou airport to Jinjiang airport,we will pick you up from Jinjiang Airport.

Or take the high speed train From Guangzhou South to Quanzhou train station.

(8 Working Hours):

Processing equipment in the workshop

Application of QT4-15 Automatic Block,paver making machine on site

QT4-15 makes Rectangle Paver(Quad Cabro in Kenya ) with size 200x100x60mm at 16pcs/mould;

QT4-15 makes Rectangle Paver(Quad Cabro in Kenya ) with size 200x100x60mm at 16pcs/mould;For making Interlocking paver (Zigzag paver) with the size at 225x112.5x60mm at 14pcs/mould.

For hollow block at 390x140x190mm, at 6pcs/mould.

For making Fly ash brick at 230x110x75mm,the capacity is 14pcs/cycle.

For making Fly ash brick at 230x110x75mm,the capacity is 14pcs/cycle. Interlocking hollow block made by QT4-15 block making machine and its application on construction site.

Interlocking hollow block made by QT4-15 block making machine and its application on construction site.Container loading in workshp for customers overseas

Block and Brick Sample

Application:

Company Information

Company Information(1) Hawen block making machines are for the manufacture of concrete bricks, blocks and paving stone,with ISO9001:2015 Quality Management Certificate,all block and brick making machines are manufactured to ISO Certification specs with state-of-the art technology;

(2) The machines are manufactured to heavy-duty standards to ensure long life, high performance and the manufacture of quality products.

(3) Hawen block making equipments are for every aspect of concrete products solution,such as common masonry like block &brick,Paving stone ,curb stone,patio stone,segmental retailing wall products,fencing units,other landscape prodcts.

(4) We offer a large ranges of stationary machines with various capacities and various pallets size that will fullfill you needs with different investment budget;

(5) Moulds: Our moulds are innovative,versatile and capable of making high quality of concrete products.

Factory workshop

Our Service

Pre-sale service support

According to every customer's demand and budget, we offer the professional factory set up solution, factory layout design, process flow design. More importantly, we welcome every customer to visit our factory and visit our customer site before placing the order

On-sale service support

Assist clients to finish the factory planning,like foundation construction, power preparation,water pool preparation,etc. Before delivery equipment to customers, complete debugging and checking,our machine will do hot testing in workshop with material. Provide a full instruction manual for the block making machine. Provide technical guidance for the installation , including installation advice and electrical connection.

After-sale service support

Send technicians to installation site for the guidance, equipment commissioning and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help.FAQ

1. How many square meters required to set up a block factory?

Answer: Generally,the whole factory requires 2000-3000 square meters, including the recommended workshop to cover the equipments at 300-400 square meters,equipments are suggested to keep under the shed.

2. What kind of material can be used to produce concrete block?

Answer:Crushed stone(Max.10mm),sand and Cement as raw material, coal fly ash, cinder, slag,gangue, gravel, and other industrial wastes.And if customer makes the top colored paving stone,then the face material of fine sand and white cement and pigmen are required.

3. Can I get the warranty for the machine?

Answer:The warranty for the machine is one year after installation or 15 months after shipment,whichever comes first.Spare parts will be sent to customers for free of charge during the warranty period. Warranty does not cover the wearing parts, in cases of incorrect handling, improper user, insufficient maintenance, unauthorized service or modifications to the machine, normal wear .

4.What is the delivery time?

Answer:The delivery time is 30-40 days upon receiving the down payment and mould drawing approval from customer.

5. What about your payment terms?

Answer:T/T and L/C are acceptable.

Generally,it requested to pay 30% as depoist by T/T before production, and the balance to be paid by T/T or Irrevocable,Confirmed LC at sight before shipment.

6. How to prepare the foundation for the equipments?

Answer:The foundation drawing for the whole plant will be provided within 07 days after the order confirmed,customer could prepare the foundation construction according to the drawing provided.

7.How about the installation & commissioning ?

Answer: After the equipments arrive customer's site,and the preparation for the foundation,water & electricity are ready,we will send 1 of our technician for the installation & commissioning,the technician will train customer's staff for the operation and maintenance of equipment.

8. How about the installation cost?

Answer:We will send our technician for the installation,customer should responsiblefor all the expense and the allowance of our technician.

9. Are the machine be tested in your factory before shipment?

Answer:Yes all of our machines will be tested in our workshop before container loading.You are warmly welcome to do the inspection before shipment.

10.Can I visit your factory before placing the order and where is your factory ?You are Answer: Warmly welcome to visit our factory any time.Our factory located in Quanzhou City,Fujian Province.

The nearest airport to our factory is Jinjiang airport,which is 30 minutes to our factory by car.

How to come to your city?

You could take the international flight to Guangzhou airport first,then take the domestic flight from Guangzhou airport to Jinjiang airport,we will pick you up from Jinjiang Airport.

Or take the high speed train From Guangzhou South to Quanzhou train station.