Metal Roofing Sheet Rib Pbr Corrugated Step Tile Wall Panel Making Machine Metcoppo Aluminum Glazed Q Tile Double Layer Forming Machine

General Industry Tech Hebei Developing Co., Ltd.- After-sales Service:Video Techenical Support

- Warranty:2 Years

- Tile Type:Colored Steel

- Certification:CE

- Condition:New

- Customized:Customized

Base Info

- Model NO.:ZTRFM

- Usage:Roof, Wall

- Transmission Method:Chains

- Name:Automatic Long Span Roof Sheet Forming Machine Tra

- Use:Roof Sheet and Wall Panel

- Voltage:380V 50Hz 3phase

- Motor:5.5kw

- Basic Frame:350h Steel

- Machine Structure:Middle Plate

- Shaft Material:45# Steel

- Shaft Diameter:80mm

- Roller Material:45# Steel Chromed

- PLC Brand:Delta

- Screen:Touch Screen

- Dimenssion:9500*1450*1500

- Raw Material:PPGI,PPGL,Gi,Gl

- Raw Material Thickness:0.3-0.8mm

- Blade Material:Gcr12 Quenched

- Transport Package:Standard Packing

- Specification:9500*1450*1500

- Trademark:ZTRFM

- Origin:Botou, Hebei, China

- HS Code:8474801

- Production Capacity:300 Sets

Description

Basic Info.

Model NO. ZTRFM Usage Roof, Wall Transmission Method Chains Name Automatic Long Span Roof Sheet Forming Machine Tra Use Roof Sheet and Wall Panel Voltage 380V 50Hz 3phase Motor 5.5kw Basic Frame 350h Steel Machine Structure Middle Plate Shaft Material 45# Steel Shaft Diameter 80mm Roller Material 45# Steel Chromed PLC Brand Delta Screen Touch Screen Dimenssion 9500*1450*1500 Raw Material PPGI,PPGL,Gi,Gl Raw Material Thickness 0.3-0.8mm Blade Material Gcr12 Quenched Transport Package Standard Packing Specification 9500*1450*1500 Trademark ZTRFM Origin Botou, Hebei, China HS Code 8474801 Production Capacity 300 SetsProduct Description

Metal Roofing Sheet RIB PBR Panel Double Layer Forming MachineIt is suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls and interior and exterior wall decorations of large-span steel structure houses. It has light weight, high strength, rich color, convenient and quick construction, earthquake resistance, fire protection, rain protection, and longevity. Long, maintenance-free and other characteristics have been widely promoted and applied.

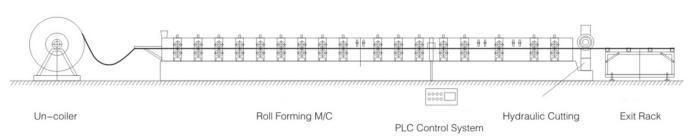

Working flow:

1.decoiler(regular 5T manual decoiler, also can equip with hydraulic decoiler)

inner diameter:450mm to 550mm

outer diameter:1500mm

width:1250mm max

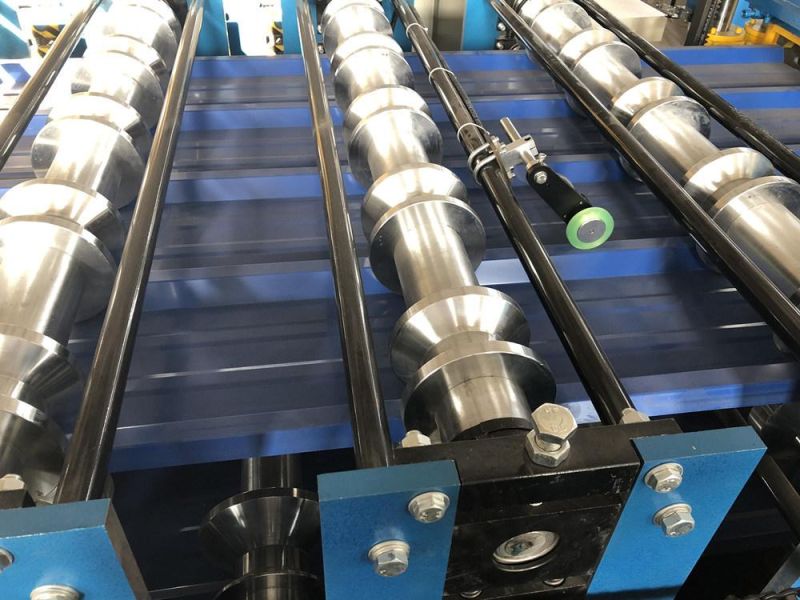

2. Main roll forming machine

feeding device: set up turnable rubber covered the roller on the bottom of the device;

the width can adjust through the hand wheels.

basic frame: 350H steel welded

machine structure: middle plate welded

roller station: 22 stations

roller material: 45# steel with quenched treatment and hard chroming

shaft diameter: 80mm,solid

shaft material: 45# steel with tempering treatment

motor power: 5.5 kw

speed: 0-20m/min

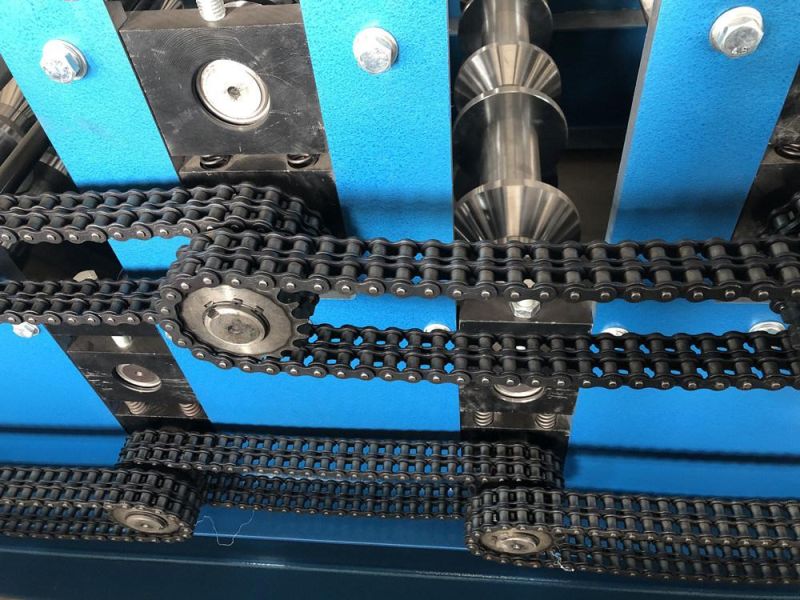

transmission: by double chains

voltage: 380V,50HZ,3Phase

3.Cutting system

blade material: Cr12,with quenched treatment

motor power: 4 kw

cutting tolerance: +/-1 mm

cooling system: With fan cooling

cutting type: Hydraulic cutting

feature: Low noise and high performance

4.PLC control system

PLC brand: Delta from Taiwan

Frequency converter brand: Delta from Taiwan

Encoder: Omron

Function: Automatic control the length,quantity and batch

5. Hydraulic station

5. Hydraulic stationhydraulic oil: No.46 oil

motor:4kw

All the tubes and wires will be marked by the numbers or letters, so that it will be very easy to connect for the new

5.Runout table

FAQ:

FAQ:Q1. Can you manufacture the roll forming machine according to my profile drawing or picture of finished product ?

A: Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine.

Q2. How can we be assured that you will deliver us quality machine with spare parts ?

A: 1. Customers can come to our factory, or send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer's factory for the installation of the machine.

Q3. What's your payment terms and delivery time?

A: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 45 workdays for delivery.

Q4. Do you have after-sales support?

A: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q5. Do you sell only standard machines?

A: No, most of our machines are customized according to customers specifications, also adopt top brand components.

Q6. What will you do if the machine is broken?

A: We provide 1 year free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine.

Q7. Can you be responsible for transport?

A: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q8. How to visit your company?

A:1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2)Fly to Tianjin airport, By high speed train From Tianjin to Cangzhou Xi (0.5 hour).

3) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.