Qt6-15 Excellent Performance Block Making Machine, Concrete Block Brick Machine, Convenient Operate

Linyi Duyue Import and Export Co., Ltd.- Warranty:3 Years

- Certification:CE, ISO

Base Info

- Model NO.:Qt6-15

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydraulic Shock

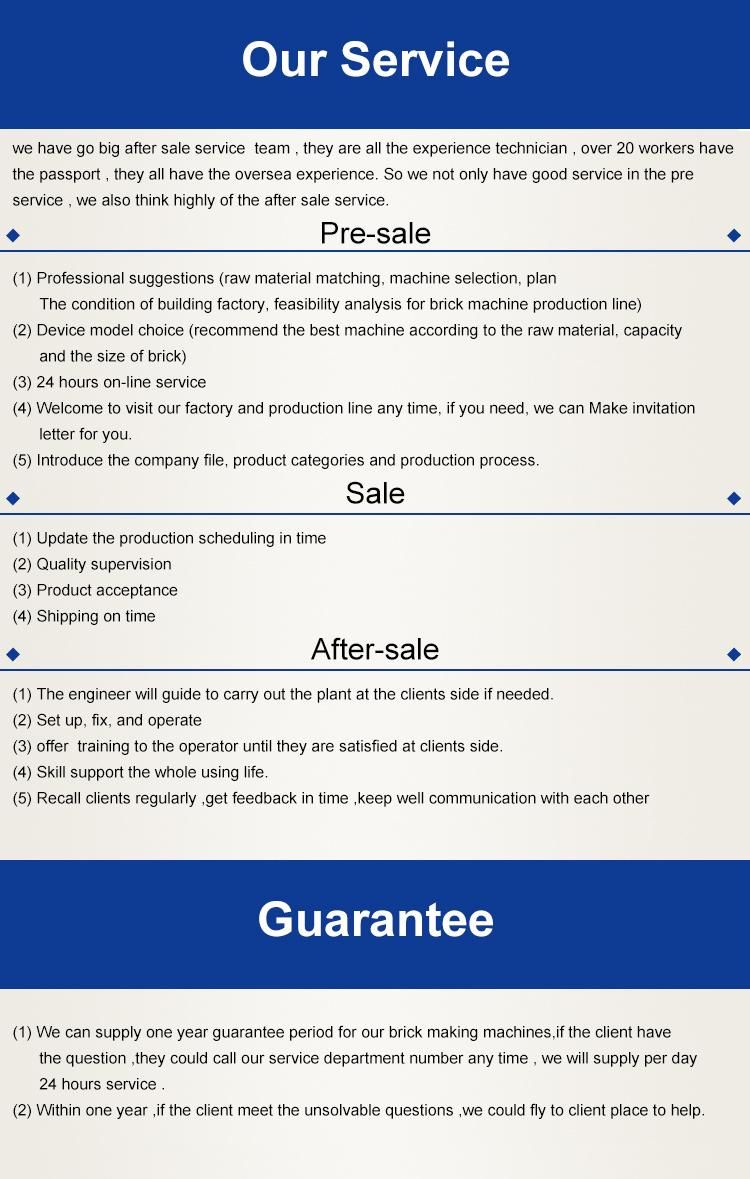

- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Pallet Size:830*940*25mm

- Color:Changeable

- Block Type:Hollow Concrete Brick Machine

- Weight:8t

- Name:Automatic Brick Making Machine

- Model:Qt6-15

- Molding Cycle:15s

- Power of Host Machine:29.1kw

- Main Market:African Countries

- Mixer Model:Js500

- Transport Package:Container

- Specification:3500*1700*2930mm

- Trademark:DUYUE

- Origin:China (Mainland)

- HS Code:8474802000

- Production Capacity:30 Sets Per Month

- Package size per unit product:4250.00cm * 1900.00cm * 2500.00cm

- Gross weight per unit product:4500.000kg

Description

Basic Info.

Model NO. Qt6-15 Customized Customized Automatic Grade Automatic Type Hydraulic Shock After-Sales Service Provided Engineers Available to Service Machinery Overseas Pallet Size 830*940*25mm Color Changeable Block Type Hollow Concrete Brick Machine Weight 8t Name Automatic Brick Making Machine Model Qt6-15 Molding Cycle 15s Power of Host Machine 29.1kw Main Market African Countries Mixer Model Js500 Transport Package Container Specification 3500*1700*2930mm Trademark DUYUE Origin China (Mainland) HS Code 8474802000 Production Capacity 30 Sets Per MonthPackaging & Delivery

Package size per unit product 4250.00cm * 1900.00cm * 2500.00cm Gross weight per unit product 4500.000kgProduct Description

Production description

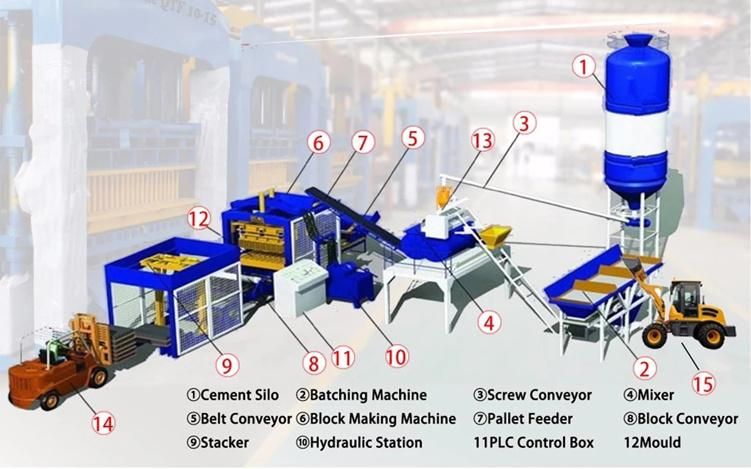

Advangtage of QT6-15 High Production Fully Automatic Hydraulic Concrete Hollow Block Machine Cement Paver Machine Curbstone Making Mahcine Line

1.Use Germany Siemens PLC control system and Siemens Touch Screen, Omron relays and contactors:

© Siemens PLC, with great adaptability, guarantees the stability and reliability of the machine.

© Visualization touch screen, with easy operation;

© High-quality electrical components from Omron;

2.Use Frequency Conversional Control Technology, which controls the block making:

© Frequency Conversion Control:Guarantees the precise and parallel movement between tamper head and mould, protects the products from transfiguration;Increases the production rate by improving the vibrating efficiency;

© Controls the instantaneous start and stop of the motors, to protect the motor from over-heating caused by constant working;

© Power saving:30%;

3.Use Double high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure:

© Buffer the hydraulic cylinder, to protect the cylinder from damage caused by inertia;

© Guarantee production stability;

4.360° Multi-Shaft Rotating and Compulsory Feeding:

© Speedy and rotating feeding, with uniform mixing, to make sure that the density and intensity of the products are guaranteed

© This uniform feeding is applicable for different kinds of raw materials and moulds;

5.Use heat treatment on moulds and main parts of the machines:

© Heavy duty machine structure and wear resistant moulds;

© The hardness reaches up to HRC 52-58;

© Greatly improves the using lifetime of the machine by 50%.

Main technical parameters

Product details

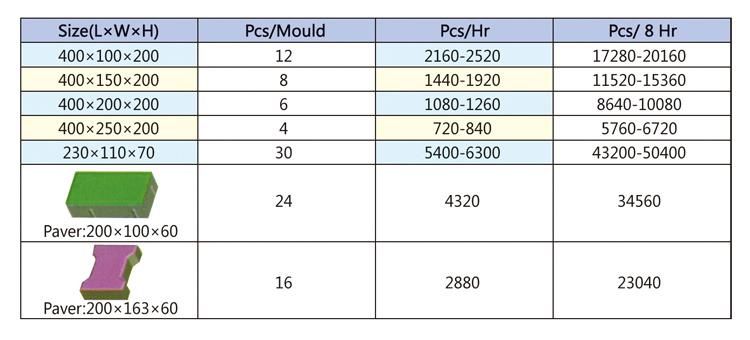

Theoretical production efficiency

Duyue Industry Co.,LTD