Cy2-10 Full Automatic Hydraulic Clay Interlock Lego Brick Machine Production Line in Cameroon

Linyi Chuangyun Import & Export Co., Ltd.- Certification:CE, ISO, SGS,Co,Coc,Pvoc,Soncap

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydroforming

- Model:Cy2-10 Clay Brick Making Machine

- Machine Capacity:4000-6000 Bricks Per Day

Base Info

- Model NO.:CY2-10

- Motor Brand:Siemens , Chinese Top Brand

- Products:Soil Interlocking Bricks, Hydraform Products

- Power Supply:Electricity , Diesel

- Power:7.5kw

- Shaping Cycle:10-15s

- Customize:Available

- Voltage:220V,380V,440V Three Phase

- Mixer Model:Jq350

- Applicable Industries:Building Material Shops, Manufacturing Plant

- Deal Method:Wholesale, Distributor, Retail

- Minimum Order Quantity:1 Set

- Cooling Method:Water Cooling

- Color:as You Need

- Transport Package:Nude Pack Well Fixed in Full Container

- Specification:235# steel for machine frame

- Origin:China

- HS Code:8474802000

- Production Capacity:3000 Bricks , Day

Description

Basic Info.

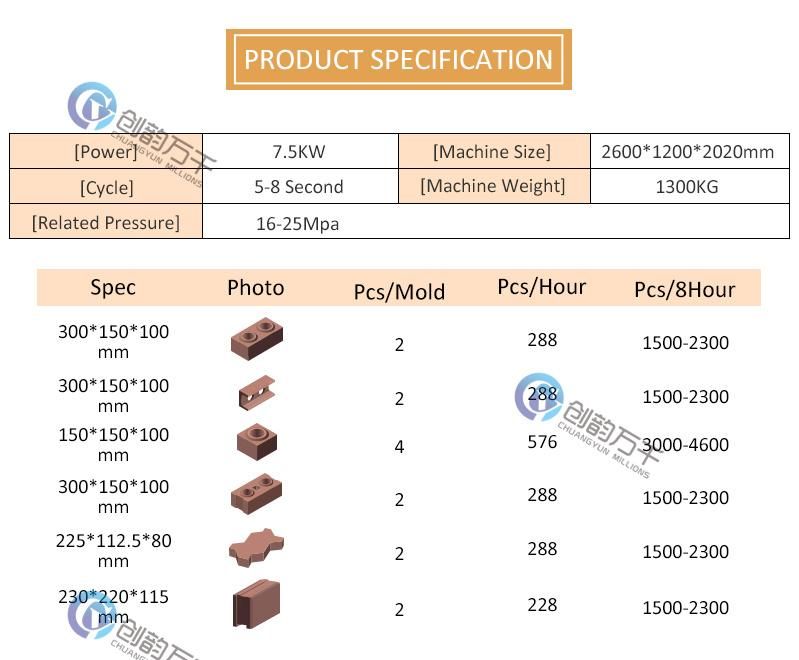

Model NO. CY2-10 Motor Brand Siemens / Chinese Top Brand Products Soil Interlocking Bricks, Hydraform Products Power Supply Electricity / Diesel Power 7.5kw Shaping Cycle 10-15s Customize Available Voltage 220V/380V/440V Three Phase Mixer Model Jq350 Applicable Industries Building Material Shops, Manufacturing Plant Deal Method Wholesale, Distributor, Retail Minimum Order Quantity 1 Set Cooling Method Water Cooling Color as You Need Transport Package Nude Pack Well Fixed in Full Container Specification 235# steel for machine frame Origin China HS Code 8474802000 Production Capacity 3000 Bricks / DayProduct Description

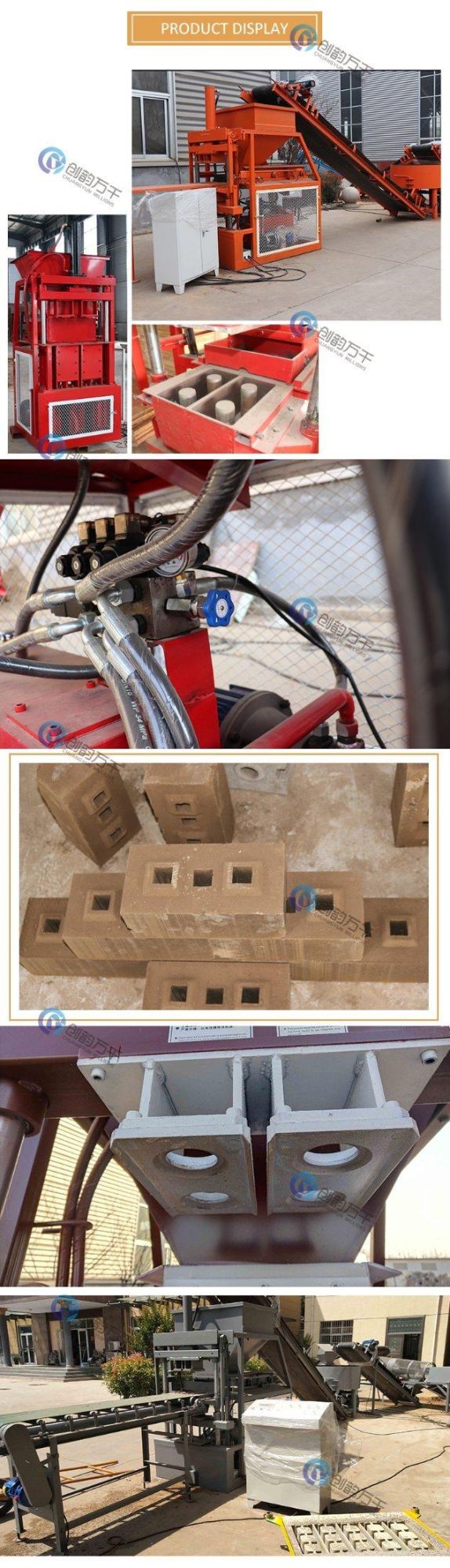

CY2-10 full automatic hydraulic clay interlock lego brick machine production line in CameroonMachine description:

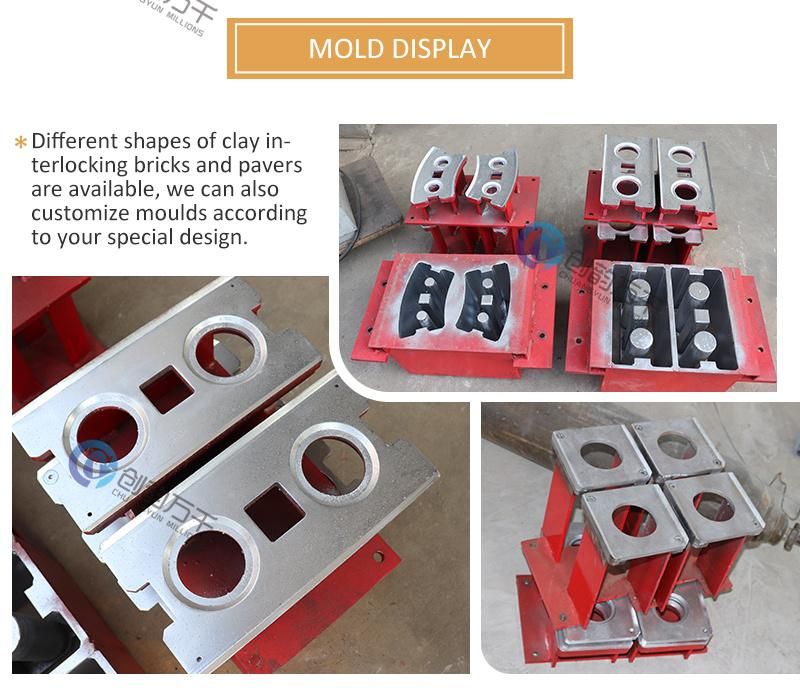

This is a fully automatic brick production machine with PLC control system. It can produce different types of bricks by changing the mold. The cycle time of the bricks is about 10 seconds and the efficiency is high.

Brick Making Process(A→F)

| Item | Name | Power | Function |

| A | Soil Crusher | 5.5KW | Crush soil into fine soil |

| B | Soil Screen | 1.1kw | Select fine soil |

| C | 3M Belt Conveyor | 0.75KW | Carry fine soil from Soil Screen to Mixer |

| D | JQ350 Mixer | 5.5KW | Mix raw material, such as soil, cement and water |

| E | 5M Belt Conveyor | 0.75KW | Carry mixed material from Mixer to Brick Machine |

| F | CY2-10 Brick Machine | 7.5KW | Produce designs of interlocking bricks and pavers |

FAQs

1. Q: What kinds of the brick making machines can be choosed for customers?

A: We have full-automatic, semi-automatic, manual, mobile, egg laying, paver machine for your choice.

2. Q: What kind of payment terms do we accept?

A:T/T, L/C, Paypal, Western Union are commom for us. Other ways are ok by negotiation.

3. Q:How about your Production time?

A:Normally 20-25 days after your deposit.

4. Q:Can I vivst your factory?

A:Yes. Many domestic and international costomers visit our factory every year.

5. Q:How long is the warranty of your equipment? Do you supply spare parts?

A:Our warranty period is one year generally. We can supply spare parts.

6. Q:Do you provide after-sale service?

A:Yes, We have a professional after-sale service team to promptly and thoroughly solve your problems.

Contact us for more information on machine and bricks: