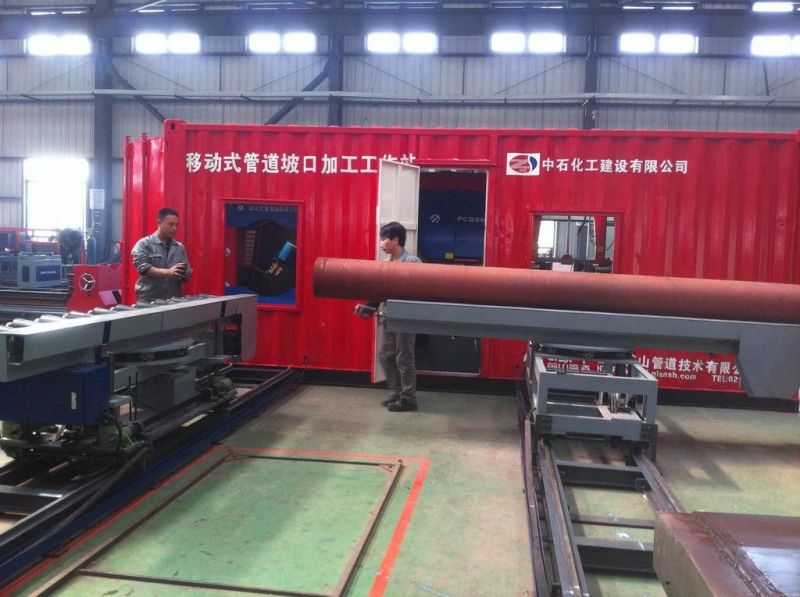

Pipe Prefabrication Production Line Container Type

Shanghai Qianshan Piping Technology Co., Ltd.- Sturcture Type:Containerized Type Piping, Pipe Spool Fabrication

- Cutting & Beveling:Cold Cutting & Beveling; Thermal Cutting & Bevelin

- Beveling Speed:<5min , Two Bevels

- Conveying Speed:2-20m,Min

- Welding Process:TIG, Mag, MIG, Saw

- Welding Type:Automatic Butt Welding

Base Info

- Model NO.:TPPPL-24A

- Automatic Welding Rate:>60%

- Voltage:380V,415V,440V-3pH

- Usage:Pipe Fabrication

- Automatic Production Line:Comprehensive

- Certification:CE, ISO, SGS

- Automation:Automation

- Flexible Production:Intelligent Manufacturing

- Rhythm:Flow Production Line

- Production Scope:Product Line

- Transport Package:Sea Worthy Packing

- Specification:CE, TUV, SGS

- Trademark:QSPT

- Origin:Made in Shanghai, China

- Production Capacity:2 Sets , Months

Description

Basic Info.

Model NO. TPPPL-24A Automatic Welding Rate >60% Voltage 380V/415V/440V-3pH Usage Pipe Fabrication Automatic Production Line Comprehensive Certification CE, ISO, SGS Automation Automation Flexible Production Intelligent Manufacturing Rhythm Flow Production Line Production Scope Product Line Transport Package Sea Worthy Packing Specification CE, TUV, SGS Trademark QSPT Origin Made in Shanghai, China Production Capacity 2 Sets / MonthsProduct Description

Pipe Prefabrication Production Line (Containerized Type );PIPE SPOOL FABRICATION PRODUCTION LINE (Movable Type)

Model: TPPPL-24

Performance Features:

1. Basic Configurationa:

Containerized Type Piping/ Pipe Spool Fabrication System

Many Sets of Pipe Cutting & Beveling Machining Workstation.

Many Sets of Mechanical Pipe Fitting Up Workstation

Many sets of Piping Automatic Welding Workstation

Many Set sof Logistics Transport System or Conveying Sstem.

A Set of Steel Structure Pipe Racks.

2. Production Efficiency: Eextremely high ( Hoisting by overhead traveling crane, Beveling by High Speed Pipe Cutting and Beveling Machine and Welding by Automatic Welding Station)

3. Applicable Industries: OIL & GAS, OIL REFINERY FACILITIES, PETROCHEMICAL, ONSHORE & OFFSHORE, CHEMICAL ENGINEERING, NUCLEAR POWER PLANT, SHIPBUILDING, POWER PLANT, ENERGY, AEROSPACE. Especially suit for field pipe prefabrication.

4. Production Capacity: 20, 000~150, 000 DI/ month (or depend on filed size or machines config), reduce manpower input, improve automation level & efficiency, and save much more cost.

5. Reference List: CNPC, SINOPEC, CNOOC, CNCEC, K. S. S, L & T, CSIC, CSSC, MCC, TECHNIP, TYCO, KEPPEL, DYNA-MAC, SOCOMENIN, C. C. C, CNEG, CHIYODA, EIL, PEC, CASC, ONSHORE etc.

6. Welcome to visiting our factory or project site at any time in Shanghai City, P. R. China; For more detail information please contact us. Thank you!

| Technical Description | Standard Type : | Custom-Made : |

Suit for Pipe Diameter: | 2" -16" /24" /32" | 2" -40" /48" or above |

Pipe Wall Thickness: | 3-80 (mm) | 3-80 (mm) |

Conveying Speed: | 2-20 m/min | 2-20 m/min |

Welding type: | Automatic root pass, fill in & final pass | Automatic root pass, fill in & final pass |

Welding Process: | TIG/MIG/MAG/SAW | TIG/MIG/MAG/SAW |

| Automatic Pipe Welding Rate: | ≥ 60% | ≥ 60% |

| Pipe Cutting & Beveling Speed: | ≤ 5min/ two bevels(8" Sch40) | ≤ 5min/ two bevels(8" Sch40) |

| Pipe Spool Prefabrication Ratio: | ≥ 60%-80% | ≥ 60%-80% |

| Piping Design Software: | PDSOFT 3D Piping | PDSOFT 3D Piping |

| Process Management Software: | PDSOFT SPFMS | PDSOFT SPFMS |