PP Flooring Single Screw Extruding / Extrusion / Making Machinery / Machine

Wuxi Boyu Plastic Machinery Co., Ltd.- After-sales Service:Boyu

- Warranty:1 Year

- Product Type:Flooring Machine

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Single-Screw

Base Info

- Model NO.:BOYU-A

- Certification:CE, ISO, UL

- Condition:New

- Customized:Customized

- High Tech:PLC Control System

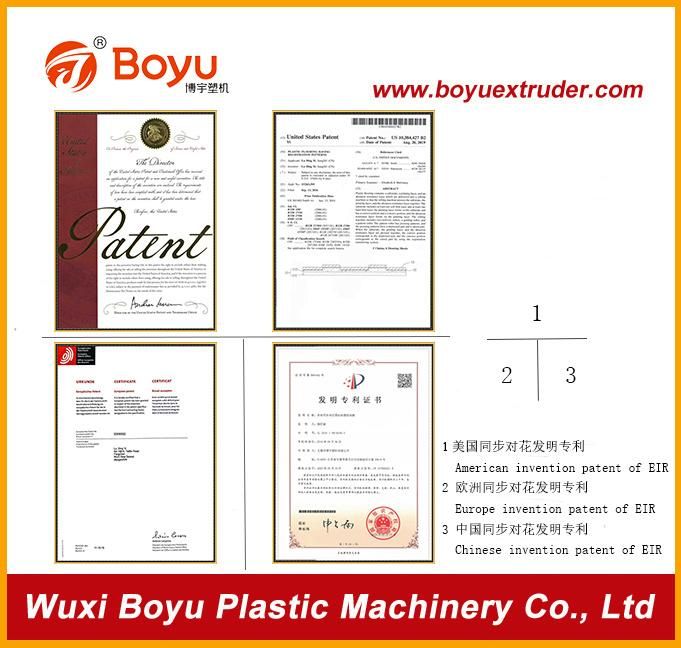

- Online Eir Embossing:USA, European, Chinese Eir Patent

- Main Motor:Siemens,Weg Ie3

- Transport Package:PVC Film, Fixed Suitable for Transporatation

- Specification:50 m

- Trademark:BOYU

- Origin:China

- HS Code:8477209000

- Production Capacity:20 Lines,Month

Description

Basic Info.

Model NO. BOYU-A Certification CE, ISO, UL Condition New Customized Customized High Tech PLC Control System Online Eir Embossing USA, European, Chinese Eir Patent Main Motor Siemens/Weg Ie3 Transport Package PVC Film, Fixed Suitable for Transporatation Specification 50 m Trademark BOYU Origin China HS Code 8477209000 Production Capacity 20 Lines/MonthProduct Description

The launch of a Innovation

Proven technology with a new product concept and an attractive price-performance ratio

As SPC flooring equipment inventor, we Boyu Extruder are always keeping moving on new research and development. we now are in great confidence to launch a new extrusion production line to all of our customers and help them enjoy more BENEFITS proactively.

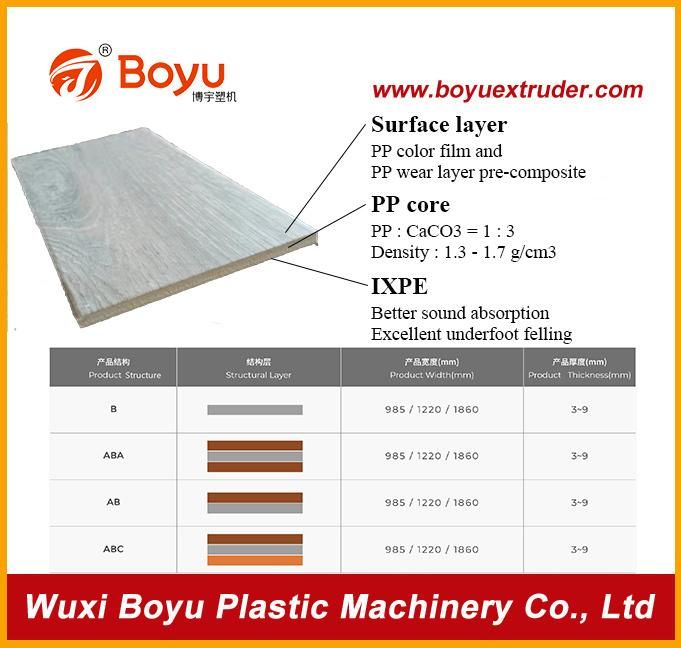

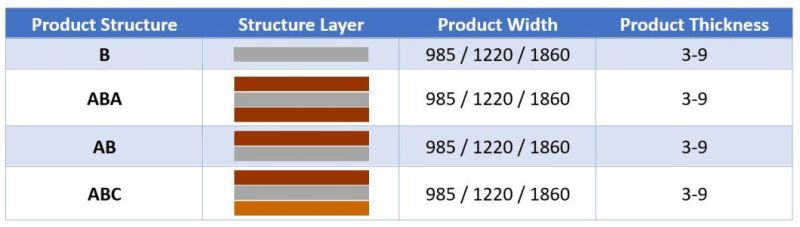

PP Flooring Production Line / PP extrusion Line/ Plastic Machine / Extruder

Advantages of PP floor

1.PP floor has low density and lighter weight than SPC floor

2.Responding to the EU's plastic ban

3.PP material is degradable

4.PP floor is halogen-free and smoke-free during the combustion process

5.The fire rating of PP flooring is v1-v0

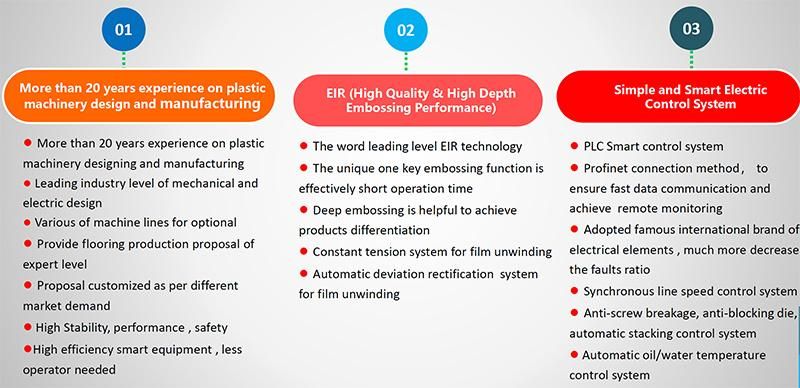

Advantages of BOYU's PP flooring production line

1.Power-saving

2.High productivity

3.Intelligent electronic control system

4.Stable performance and low failure rate

1. PP Flooring Production Line / PP extrusion Line/ Plastic Machine / Extruder Design parameters

| No. | Items | Data |

| 01 | Total Power | 520KW |

| 02 | Raw Material | PP powder, calcium carbonate, stabilizer, lubricant, small materials |

| 03 | Main material proportion | PP: CACO3= 1:3 |

| 04 | Product specifications | Width:985/1220/1860mm,Thickness:3-9mm |

| 05 | Machine Fabrication Certificate | CE |

| 06 | Electric components certificate | CE |

2. PP Flooring Production Line / PP extrusion Line/ Plastic Machine / Extruder Equipment List

Extruder → T-die → Four rollers Calender → Oil temperature controller →Two rollers embossing machine → Traction machine → Cutting machine → Automatic flipper & Stacker

3. PP Flooring Production Line / PP extrusion Line/ Plastic Machine / Extruder model

| Model No. | Screw specifications Φ(mm) | Capacity/h | Installed power | Operating power |

| BOYU-A | Φ90*2 | 1 Ton | 320 KW | 220 KW |

| BOYU-B | Φ135 | 1.5 Ton | 400 KW | 280 KW |

| BOYU-C | Φ160 | 2.5 Ton | 500 KW | 350 KW |

4.PP Flooring Production Line / PP extrusion Line/ Plastic Machine / Extruder Finished board

5.EIR Patent

6. Advantages of BOYU production line

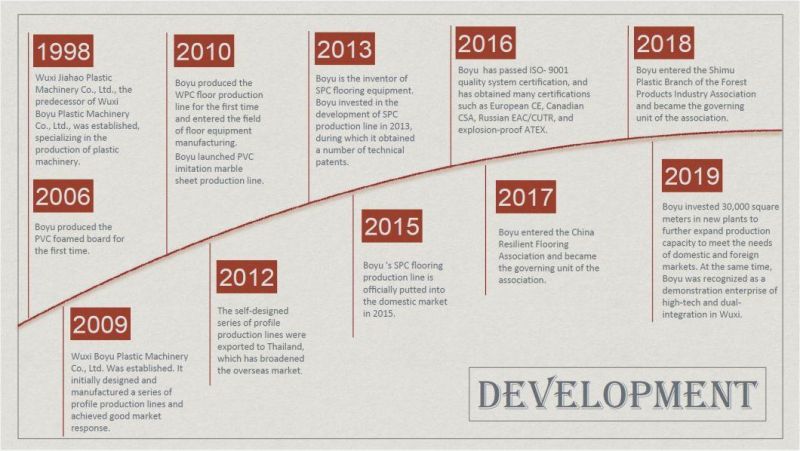

7. Boyu Development

8.Our Services

9.Shipping

10. Boyu projects

10. Boyu projects