Automatic Ajusted Z Section Stud Roll Forming Machine for Steel Construction

Cangzhou Nexus Machinery Co., Ltd.- After-sales Service:Provide Overseas Service

- Warranty:1 Year

- Certification:CE, ISO9001

- Customized:Customized

- Condition:New

- Control Type:Electric

Base Info

- Model NO.:NX80-300

- Automatic Grade:Automatic

- Product Name:Ajusted Z Section Stud Roll Forming Machine

- Coil Material Thickness:1--3mm

- Processing Material:Galvanized Steel

- Roller Material:Cr12MOV

- Main Frame:400mm H-Beam

- Total Power:22 Kw

- Forming Speed:12-24m,Min

- Roll Station:18 Stands

- Roller Diameter:80mm

- Effective Width:80-300mm

- Transport Package:Plastic Film

- Specification:80-300

- Trademark:Nexus Machinery

- Origin:Cangzhou

- Production Capacity:10

Description

Basic Info.

Model NO. NX80-300 Automatic Grade Automatic Product Name Ajusted Z Section Stud Roll Forming Machine Coil Material Thickness 1--3mm Processing Material Galvanized Steel Roller Material Cr12MOV Main Frame 400mm H-Beam Total Power 22 Kw Forming Speed 12-24m/Min Roll Station 18 Stands Roller Diameter 80mm Effective Width 80-300mm Transport Package Plastic Film Specification 80-300 Trademark Nexus Machinery Origin Cangzhou Production Capacity 10Product Description

C Z Purlin Cold Roll Forming MachineAutomatic Ajusted Z Section Stud Roll Forming Machine For Steel Construction

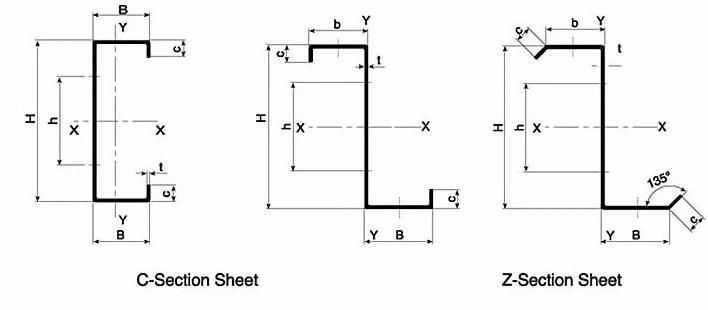

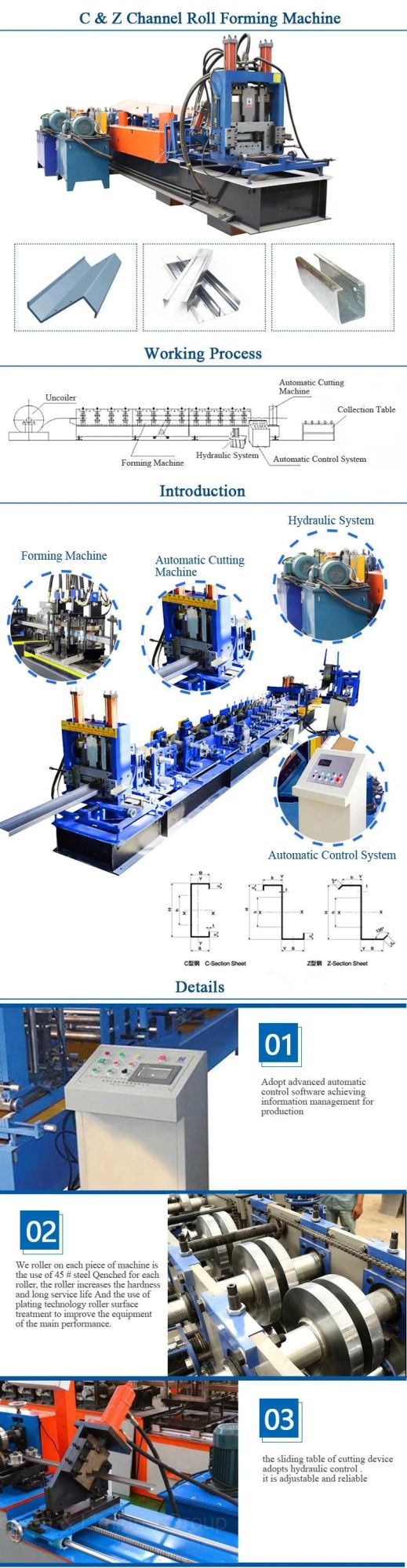

The Automatic Ajusted Z Section Stud Roll Forming Machine For Steel Construction can produce C and Z profiles. Produce the C and Z purlin by exchange one side of the roller up and down. Greatly improved the production efficiency and save the working space. The driving way is chain drive. Our C / Z channel purlin roll forming machine can be profile custom, and are lower cost, high efficiency, reliable working ,low energy consumption. We can do any type of equipment according to customer requirements.

Echnical parameters for Automatic Ajusted Z Section Stud Roll Forming Machine For Steel Construction :

| Configurations | Manual Uncoiler, Guiding Platform, 9 Shaft Strip Leveler, Main Machine Of Roll Forming, Hydraulic Motor, Pre-Punching Device,Pre-Cutting Device, Hydraulic Station, PLC Control, Supporter Table. |

| Control System | PLC Inverter Encoder Touch Screen |

| Main Frame | 400mm H-Beam |

| Total Power | 22 kw |

| Power Supply | 380V, 3-Phase,50Hz |

| Forming Speed | 12-24m/min |

| Roll Station | 18 stands |

| Decoiler capacity | 3.5 tons |

| Roller Diameter | 80mm |

| Effective Width | 80-300mm |

| Feeding Thickness | 1-3.0mm |

| Backboard Thickness | 20mm |

| Cutter Standard | GCr12 |

| Roller Standard | Gcr15# |

| Overall Size | About 8500×1000×1400mm |

| Total Weight | About 10T |

| Custom | According to customer's requirements |

ABOUT US:

Cangzhou Nexus Machinery Co.,Ltd is experienced manufacturer & exporter of cold roll forming machine with ISO quality system.

Our R&D department is staffed with senior engineers who has more than 20 years experience in metal forming machine industry, so we are able to assist customers with professional designing and solution.

Our range of products: roof tile roll forming machine, cladding roll forming machine, metal decking roll forming machines, C/U/Z/W/L steel purlin roll forming machine etc. We also can supply steel coils, roof panels to suit diverse requirements of our global customers.

Today, we have exported our machines to America, Chile, Mexico, Bolivia, Brazil, Colombia, Argentina, Ecuador, Honduras, Fiji, Papua New Guinea, Kuwait, Syria, Oman, Saudi Arabia, U.A.E, Nigeria, Tanzania,Ethiopia, Gana, Guinea,South Sudan, Algeria, Niger, Philippines,Indonesia,India, Azerbaijan and Kazakhstan.

We have rich experience for cold roll forming machine solution,competitive price and excellent service. We will continue to do our best to supply perfect products and service for customers. Invite you to contact us for further information.