Grinding Ball Mill for Cement

Henan Zhengzhou Mining Machinery Co., Ltd.- Application:Construction

- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Training:on Site

- Certificate:ISO9001,ISO14000,Ce

Base Info

- Model NO.:1.2x4.5-4.2x13

- Condition:New

- Model Selected:We Offer

- After Sale Service:for The Whole Using Life

- Spare Parts:Supply for The Whole Year Freely

- Firm Established:1956

- Testing:Supply

- Warranty:One Year

- Design:We Offer

- Transport Package:Packing in Standard Containers or Meet Your Demand

- Specification:ISO9001, ISO14000, CE

- Trademark:zhengkuang

- Origin:Henan, China (Mainland)

- HS Code:8417

- Production Capacity:1.4-87 T,H

Description

Basic Info.

Model NO. 1.2x4.5-4.2x13 Condition New Model Selected We Offer After Sale Service for The Whole Using Life Spare Parts Supply for The Whole Year Freely Firm Established 1956 Testing Supply Warranty One Year Design We Offer Transport Package Packing in Standard Containers or Meet Your Demand Specification ISO9001, ISO14000, CE Trademark zhengkuang Origin Henan, China (Mainland) HS Code 8417 Production Capacity 1.4-87 T/HProduct Description

Grinding Ball Mill for CementProduction introduction of cement ball mill

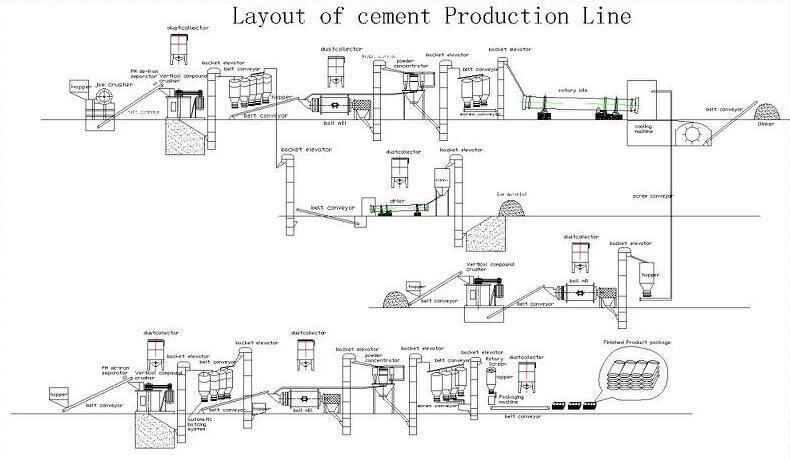

The cement production line includes vibrating feeder, jaw crusher, impact crusher, vertical mill, preheating system, cement rotary kiln, cement ball mill, packing machine and so on.

All the necessary equipment in this line can be provided by our factory. We have cement production line experts to design specific solutions for your reference.

Material needed for making cement:

Limestone crushing: limestone is the main raw material for cement making, but since natural limestone is usually big, we use cement limestone crusher to crush them into small particles.

Bauxite crushing: bauxite is the addictive. For making cement raw materials, bauxite is crushed by cement equipment into powder. Then bauxite particles and limestone particles together are ground into raw powder by raw mill.

Coal crushing: coal powder is used to be processed into cement clinker. Raw coal is crushed by cement plant then ground by cement coal mill.

Gypsum crushing:gypsum powder made by gypsum crusher and gypsum mill is put into cement clinker together with coal powder, and then the cement raw material enters into the cement mill for fine grinding.

Our service:

Training & Service

Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacturer equipment,

according to your special demand.

Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators

and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory?level of spare parts, which means the replacements can be shipped to you right away.

Welcome to visit our company and workshop, we sincerely look forward to cooperating with

you. We will provide you with the most suitable products with the reasonable price.