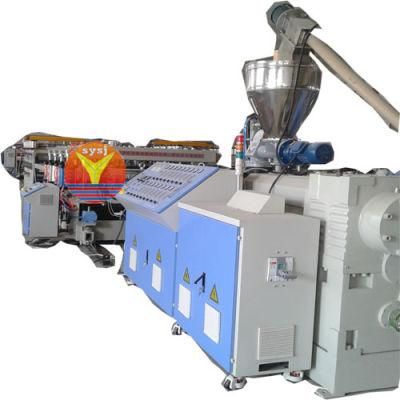

Plastic Construction Board Production Line for Building Boards

Qingdao Sanyi Plastic Machinery Co., Ltd.- Product Type:Extrusion Molding Machine

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Type:Sheet Extruder

- Screw:Twin-Screw

- Automation:Automatic

Base Info

- Model NO.:SJSZ80,156, sjsz80173

- Computerized:Computerized

- Plastic Processed:PVC

- Feeding Mode:One Feed

- Assembly Structure:Separate Type Extruder

- Exhaust:Exhaust

- Transport Package:on Demand

- Specification:1220x2440mm

- Trademark:SANYI

- Origin:China

- HS Code:847780000

- Production Capacity:350-400kg,H

Description

1

SJSZ 80/156 Conicaltwin Screw Extruder

ABB frequency converter,

SIEMENS

Auxiliary machine

(controlled by Inverter)

with automatic dust collector

C.Process :

Material: PVC+additives or PVC+wood powder+additives

Material-mixer-extruder-Hanger-style head mould-Cooling calibrating mould-Cooling carrying roller and edge-cutting device-Haul-off machine-cutting machine-Delivery device

F.Our SERVICE

1. Pre-sale service:

· To provide information and market research,to provide consultation,to provide many kinds of conveniences and market service,etc. Products: PVC Foam Board Machine...

· The main purpose of pre-sales service is to help customers make the project planning and system requirements analysis. Make our products maximum to meet clients' requirements. Also play the greatest overall economic benefits of customers' investment.

2. After-sale service:

· To install products and test products freely for customers.

· To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

· To direct technology aspect of relevant use according to customers' requirements

· To provide technical training for clients' employees.

· To be responsible for maintenance service, door-to-door service under the necessary circumstance.

3.Technology support:

· To provide installation and test for the machine.

· To provide formulas and technology of relevant products.

· To provide information of chemical material manufactories.

· To provide technical training for clients' employees.