Economial Hot Friction Saw for Carbon Steel Pipes High Frequency Straight Welded

JIANGSU NEW VICTOR INDUSTRIAL CO., LTD.- After-sales Service:for All Machine Life

- Warranty:1 Year Warranty

- Pipe Material:Carbon Steel

- Condition:New

- Customized:Customized

- Theory:Inverter

Base Info

- Application:Industry

- Type:Auto Stacking and Bundling

- Driving System:Yaskawa Servo Motors and Inverters

- Control System:PLC (Imported Brand)

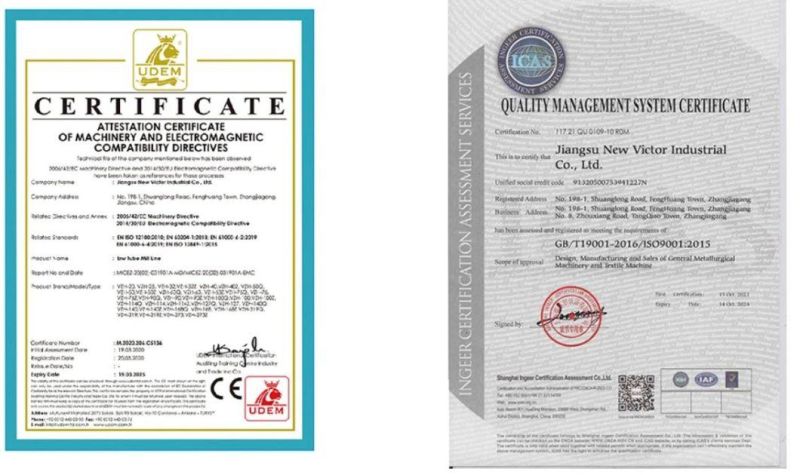

- Certification:CE, ISO, SGS

- After Warranty Service:Video Technical Support, Online Support etc

- Round Pipe Diameter:12 mm to 273 mm

- Round Pipe Thickness:0.2mm~12mm

- Square /Rectangular Size:8*8 mm to 200*200 mm

- Square /Rectangular Thickness:0.25 mm to 11 mm

- Advantage Option:Automatic Production

- Usage Life:Over 30 Years

- Trade Mark:New Victor

- Transport Package:Sea Worthy Packing

- Specification:whole production line

- Trademark:NEW VICTOR

- Origin:China

- HS Code:82021000

- Production Capacity:200,Year

Description

90×90 ~ 200×200

120×60 ~ 260×130

ROLLER QUICK CHANGE SYSTEM

ROLLER QUICK CHANGE SYSTEMchange roller in 10 minutes, resume production in 30 minutes

when changing different sizes, the middle stands with universal coupling system move backwards and release automatically from the upper and lower horizontal shafts, which is driven by motor or hydraulic system.

For small and middle size machines, lift the whole platform with horizontal & vertical stands and rollers away from the machine base, then lift another same platform with the required pipe roller installed off-line to the machine base, the middle stands with universal coupling system move forward and automatically combine the upper and lower horizontal shafts, driven by motor or hydraulic system.

For big size machines, the upper covers of horizontal stands are designed openable from side, to lift out the shafts with rollers and then lift in those shafts with required rollers installed off-line. Then the opened cover is closed and the middle stands with universal coupling system move forward and automatically combine the upper and lower horizontal shafts, driven by motor or hydraulic system.