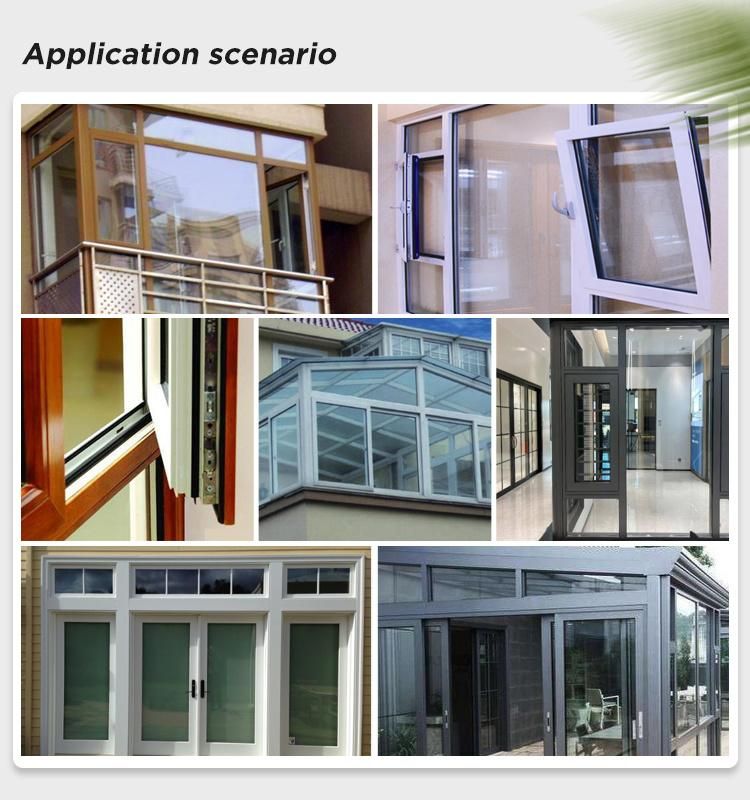

Window and Door Making Machine Digital Display Aluminum Corner Connector Cutting Saw

Jinan Seth Intelligent Equipment Co., Ltd.- Warranty:24 Month

- Condition:New

Base Info

- Model NO.:LJJA-CNC-500

- Certification:ISO, CE

- Automatic Grade:Automatic

- CNC or Not:CNC

- Voltage:380V

- Power Supply:380V,50Hz

- Motor Power:3.0kw

- Motor Speed:2800r,Min

- Working Pressure:0.6~0.8MPa

- Auto Feeding Length:2~580mm

- Cutting Width:Max. 140mm

- Cutting Height:Max. 240mm

- Cutting Length:No Limit If Seleting Manual

- Cutting Angle:90 Degrees

- Feeding Speed:Infinitely Adjustable-Speed0-3m,Min

- Saw Blade Specification:Φ500×3.8XΦ30 Z=120

- Overall Dimension:5950X1770X1840mm

- Weight:500kg

- Transport Package:Wood

- Specification:500cm

- Trademark:Seth

- Origin:Jinan

- Package size per unit product:5950.00cm * 1770.00cm * 1840.00cm

- Gross weight per unit product:500.000kg

Description

Overview

Product Description

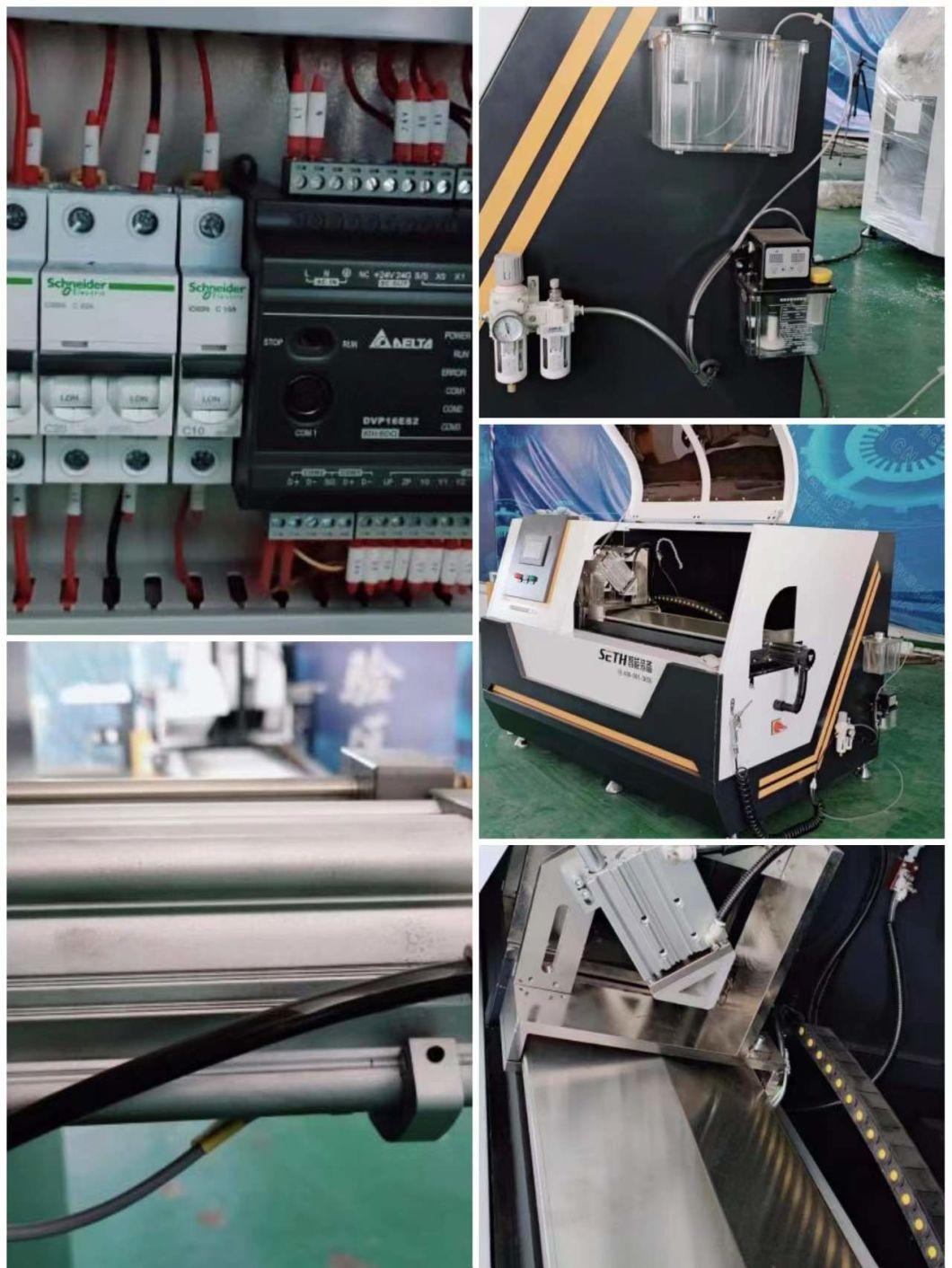

2,This machine is the latest R&D and design model of our company, which is the first in the industry with stable performance and high efficiency.

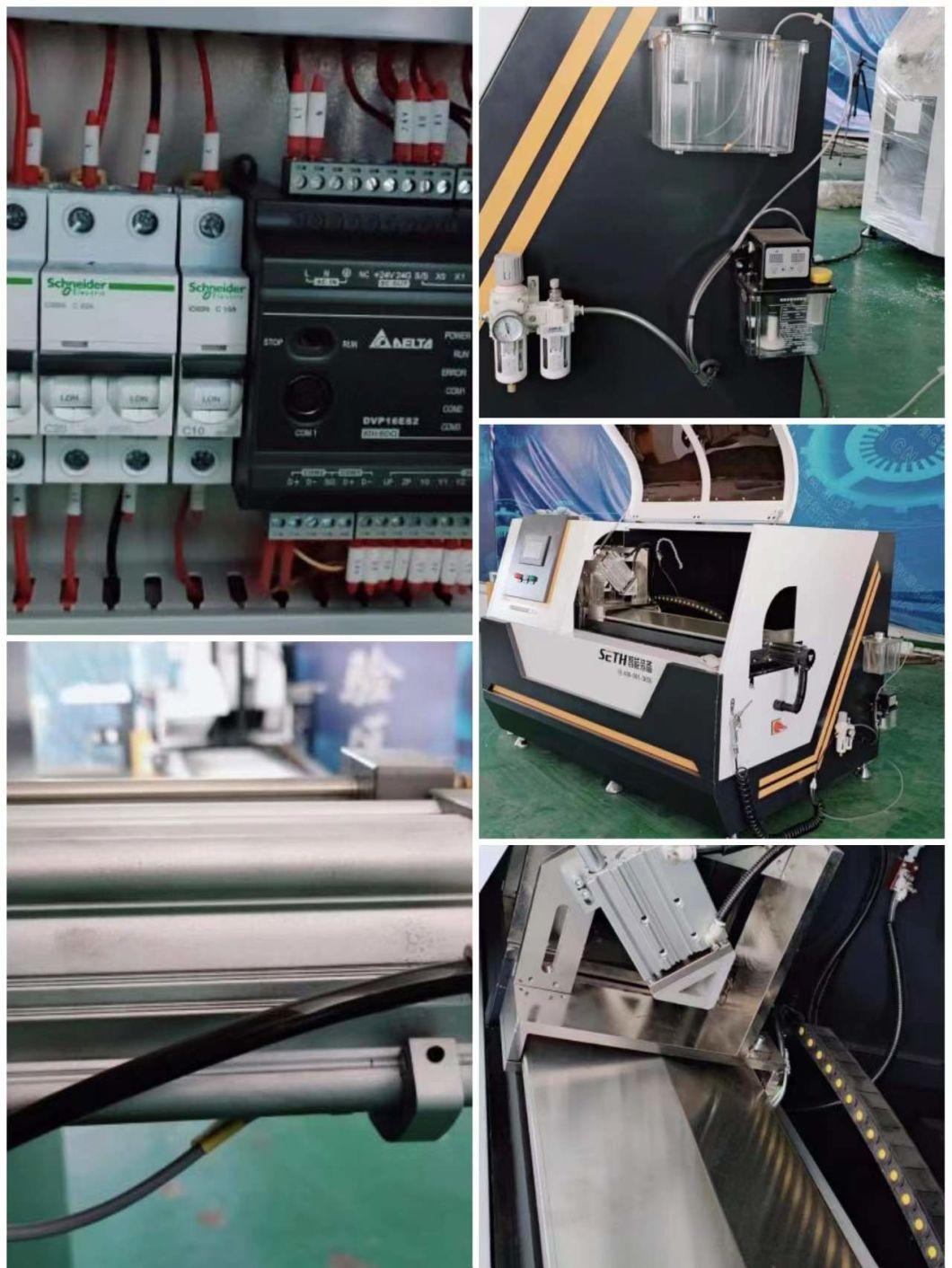

Taiwan Province Delta CNC control system is used, and the control system adopts man-machine interface, which is simple and easy to operate.

3,The cutting tool adopts cemented carbide saw blade, which has high cutting speed, high productivity and high machining precision.

4,The feed motion pair adopts linear motion bearing, which has small motion resistance and high precision.

5,The feeding mechanism adopts automatic feeding system, which is stable and reliable with high efficiency.

6,With high automation, the advance and retreat of clamping and sawing are controlled by pneumatic system, which is safe and reliable.

7,It has automatic counting function and no cutting function of tailings.

Continuous cutting of 6-meter angle profile can be realized only by clamping once.

8,Automatically save the number of cut segments in case of power failure.

Adopt micro spray cooling device to save the processing cost of doors and windows (alternative).

2,This machine is the latest R&D and design model of our company, which is the first in the industry with stable performance and high efficiency.

Taiwan Province Delta CNC control system is used, and the control system adopts man-machine interface, which is simple and easy to operate.

3,The cutting tool adopts cemented carbide saw blade, which has high cutting speed, high productivity and high machining precision.

4,The feed motion pair adopts linear motion bearing, which has small motion resistance and high precision.

5,The feeding mechanism adopts automatic feeding system, which is stable and reliable with high efficiency.

6,With high automation, the advance and retreat of clamping and sawing are controlled by pneumatic system, which is safe and reliable.

7,It has automatic counting function and no cutting function of tailings.

Continuous cutting of 6-meter angle profile can be realized only by clamping once.

8,Automatically save the number of cut segments in case of power failure.

Adopt micro spray cooling device to save the processing cost of doors and windows (alternative).