Cy2-10 Automatic Hydraulic Clay Interlocking Brick Hydraform Block Making Machine Price

Linyi Chuangyun Import & Export Co., Ltd.- Certification:CE, ISO, SGS,Co,Coc,Pvoc,Soncap

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydroforming

- Model:Cy2-10 Clay Brick Making Machine

- Machine Capacity:4000-6000 Bricks Per Day

Base Info

- Model NO.:CY2-10

- Motor Brand:Siemens , Chinese Top Brand

- Products:Soil Interlocking Bricks, Hydraform Products

- Power Supply:Electricity , Diesel

- Power:7.5kw

- Shaping Cycle:10-15s

- Customize:Available

- Voltage:220V,380V,440V Three Phase

- Mixer Model:Jq350

- Applicable Industries:Building Material Shops, Manufacturing Plant

- Deal Method:Wholesale, Distributor, Retail

- Minimum Order Quantity:1 Set

- Cooling Method:Water Cooling

- Color:as You Need

- Transport Package:Nude Pack Well Fixed in Full Container

- Specification:235# steel for machine frame

- Origin:China

- HS Code:8474802000

- Production Capacity:3000 Bricks , Day

Description

Basic Info.

Model NO. CY2-10 Motor Brand Siemens / Chinese Top Brand Products Soil Interlocking Bricks, Hydraform Products Power Supply Electricity / Diesel Power 7.5kw Shaping Cycle 10-15s Customize Available Voltage 220V/380V/440V Three Phase Mixer Model Jq350 Applicable Industries Building Material Shops, Manufacturing Plant Deal Method Wholesale, Distributor, Retail Minimum Order Quantity 1 Set Cooling Method Water Cooling Color as You Need Transport Package Nude Pack Well Fixed in Full Container Specification 235# steel for machine frame Origin China HS Code 8474802000 Production Capacity 3000 Bricks / DayProduct Description

CY2-10 automatic hydraulic clay interlocking brick hydraform block making machine priceMachine description:

This is a fully automatic brick production machine with PLC control system. It can produce different types of bricks by changing the mold. The cycle time of the bricks is about 10 seconds and the efficiency is high.

Main technical parameters

Machine details

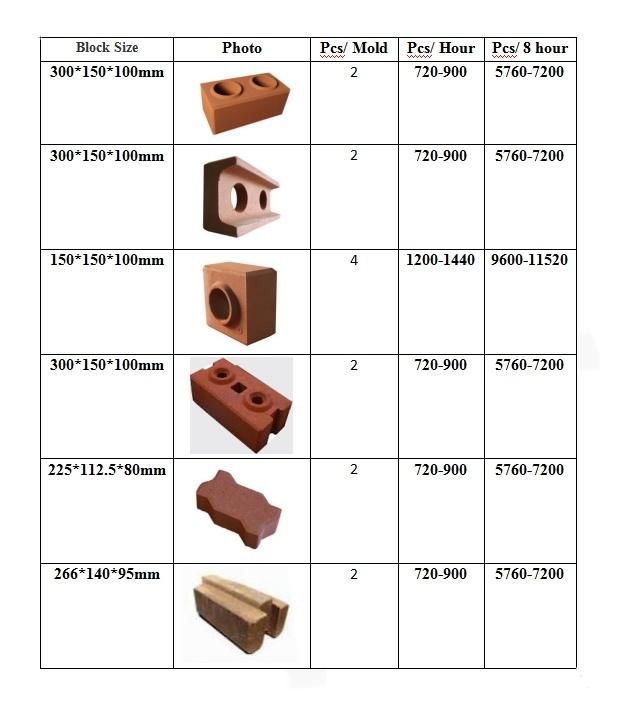

Production Capacity

Brick Making Process(A→F)

| Item | Name | Power | Function |

| A | Soil Crusher | 5.5KW | Crush soil into fine soil |

| B | Soil Screen | 1.1kw | Select fine soil |

| C | 3M Belt Conveyor | 0.75KW | Carry fine soil from Soil Screen to Mixer |

| D | JQ350 Mixer | 5.5KW | Mix raw material, such as soil, cement and water |

| E | 5M Belt Conveyor | 0.75KW | Carry mixed material from Mixer to Brick Machine |

| F | CY2-10 Brick Machine | 7.5KW | Produce designs of interlocking bricks and pavers |

Machine loading and delivery

About us

Our Company

Chuangyun Machinery is a professional manufacturer with 20 years history in concrete block machine and clay interlocking brick machine. Chuangyun Machinery factory is located in Linyi city, Shandong Province, China.

Chuangyun Machinery has been export to more than 100 countries, and are popular brick machine in Africa, South America, Asia because of the quality and good service.

Chuangyun Machinery will keep moving in improving quality of machine, perfecting after-sale service and developing new machines to meet various needs of customers.

Chuangyun Machinery will support customers with more and more success !

Our Service

Pre-Sale

- Introduce the company's basic information, product catalog and basic machine production process.

- Welcome to visit our company and products any time.If you need , we can make invitation letters for you.

- 24 hours online service.

After-Sale

- Set up, fix, and operate if buyer need.

- Provide machine-operated videos and pictures

- Send the accessories you need at any time.

- Guarantee Period: One year after installation finished at buyer's factory.

- Within one year, if the customer encounters unsolvable problems, The engineers will selectively fly to customers for local help

FAQ:

Q1: How can i trust your machine's quality?

A: Our products have been checked and got certification ISO9001, and we have exported to many countries and regions in the world, with good reputation and quality of customer feedback. In addition, every machine is carefully tested before shipment to ensure that the machine is operating perfectly when it comes to your hand.

Q2: What about payment terms?

A: 30% Deposit before production,70% before delivery when machine is ready for shipments.

Q3: How to Cure Blocks?

A: Fresh Blocks are stacked and covered with black plastic to avoid moisture loss. The blocks are then watered daily to create a greenhouse effect, allowing the cement to harden and the blocks to strengthen. Cure your blocks for a minimum of 7 days and allow the blocks to dry to another 7 days before building. This will ensure strong good quality blocks.

Q4: Can I visit your factory?

A:Yes. Many domestic and international customers visit our factory every year.

Q5: How long is the delivery time?

A:20-30 days after receipt of deposit and molds confirmation from Buyer.