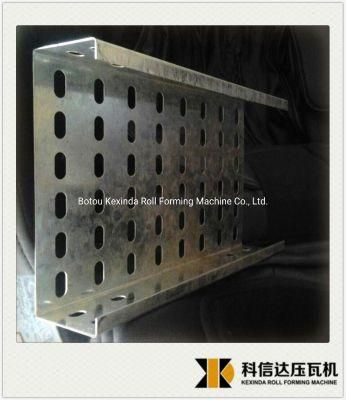

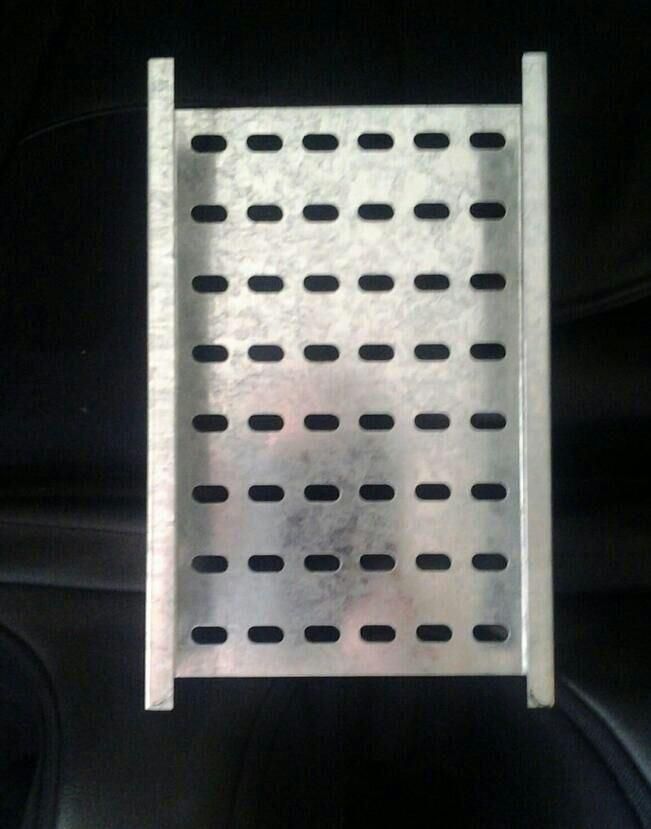

Kexinda Steel Cable Tray Roll Forming Machine

HEBEI XINNUO ROLL FORMING MACHINE CO., LTD.- Certification:CE, RoHS, ISO9001

- Customized:Customized

- Condition:New

- Control Type:CNC

- Automatic Grade:Automatic

- Drive:Electric

Base Info

- Model NO.:200-800

- Main Frame:400mm H

- Power:22kw

- Control System:PLC

- Color:by Your Choose

- Product Name:Cable Tray Rolling Machine

- Cetificate:Ce ISO

- Size:200-800

- Transport Package:Container

- Specification:11800*1500*1600mm

- Trademark:kexinda

- Origin:Hebei China

- HS Code:8455221000

- Production Capacity:10sets,Month

Description

Basic Info.

Model NO. 200-800 Main Frame 400mm H Power 22kw Control System PLC Color by Your Choose Product Name Cable Tray Rolling Machine Cetificate Ce ISO Size 200-800 Transport Package Container Specification 11800*1500*1600mm Trademark kexinda Origin Hebei China HS Code 8455221000 Production Capacity 10sets/MonthProduct Description

cable tray roll forming machine

Product DescriptionThe chart of process flow:

Decoilingactive feedingroll formingmeasuring lengthcutting to lengthproduct to stand

Main equipment:

Decoiler, main forming machine, hydraulic cutting, product stand, hydraulic systerm, electric systerm

Techenical parameters:

1Automatic inner tight decoiler

A coil inner diameter:450mm-700mm

B max width of coiling: 500mm

C max loading of cloading:4500kg

2 main forming machine:

A number of forming steps:12 or according to customers requirement

B material of shaft:45# adjustable treatment. Outer diameter 70mm

C material of roller:high grade 45# steel (plated chrome on surface)

D main motor power:22kw

E forming speed :8-12m/min or according to the customers requirement

F stand: 350#steel welding

G the plated chrome of roller surface:0.05mm

3 hydraulic cutter:

A material of blade:Cr12with quenched treatment

B cutting systerm: adopt advanced hydraulic drive, automatic cut after forming, no distortion, no waste, high safe factor(main motor stops and cut)

4 product warranty:

12 months and we will provide the technical support for the whole life of the equipment.

The chart of process flow:

A Technical specification

(1) Manual decoiler

(2) Roll-Forming M/C:

(3) Cutting Mechanism

(4) Hydraulic System

(5)Computer control cabinet :

One counter gauges length, pulses, and decides length

(7) Output table

table

Packaging & Shipping

Company Information

FAQ

1:How to play order:

Inquiry---confirm the profile drawings and price---confirm the PI---arrange the deposit or L/C---then OK

2:How to visit our company:

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi(1 hour),then we can pick up you.

Fly to Shanghai Airport:By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5hours),then we can pick up you.

If any questions,you can call me mobile phone at any times

3:When we exported the machines:

We have beening making and exporting the machines since from the year of 1998.

4:If you want to get more pictures or videos of the machines,I can send them to you by Email or Skype