Qt10-15 Automatic Block Making Machine, Concrete Hollow Block Machine, Cement Brick Forming Machine

Linyi Duyue Import and Export Co., Ltd.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydraulic Shock

- Service Provided:Engineers Available to Service Machine

- Forming Cycle:15s

Base Info

- Model NO.:Qt10-15

- Molding Area:1196*880mm

- Power of Host Machine:37kw

- Viberation Force:100kn

- Dimension of Host Machine:3500*2300*2930mm

- Weight of Host Machine:9.8t

- Mixer Model:Js750

- Water Consumpt:10-20t,Day

- Pallet Size:1300*900*30mm

- Product Name:Qt10-15 Automatic Brick Paving Machinery Price

- Transport Package:Container

- Specification:9600*1600*2700mm

- Trademark:Duyue

- Origin:Linyi City, China

- HS Code:8474802000

- Production Capacity:30 Sets Per Month

Description

Basic Info.

Model NO. Qt10-15 Molding Area 1196*880mm Power of Host Machine 37kw Viberation Force 100kn Dimension of Host Machine 3500*2300*2930mm Weight of Host Machine 9.8t Mixer Model Js750 Water Consumpt 10-20t/Day Pallet Size 1300*900*30mm Product Name Qt10-15 Automatic Brick Paving Machinery Price Transport Package Container Specification 9600*1600*2700mm Trademark Duyue Origin Linyi City, China HS Code 8474802000 Production Capacity 30 Sets Per MonthProduct Description

Production description What do you wish to manufacture today?

Production description What do you wish to manufacture today?The QT10-15 block production line is a fully automatic manufacturing unit, with a production capacity of pieces from 60 to 230mm height, allowing the manufacturing of a wide range of products for building walls, roads, garden, pavement, etc.In this unit is used a series of bamboo pallets with dimensions of 1300 x 900 x 30 therefore allowing the manufacturing of a large number of heavy weight pieces by cycle.To attain such performances the vibration becomes one of the essential points of the equipment.To guarantee a homogeneous vibration in all the worktable with the guarantee of a strong compaction of the concrete, duyue has the vibration system specially conceived to compete with the highest quality standards worldwide, this vibration system is not only an innovation but a standard for all our high performance vibropresses.Its strong structure and certified materials allow the use of very high compaction forces of approximately 100KN, the hydraulic unit that comes standard with speed control modules allows extremely fast movements with very soft transitions therefore ensuring a longer durability and low maintenance of the equipment.

Main technical parameters

Main technical parameters

Product details

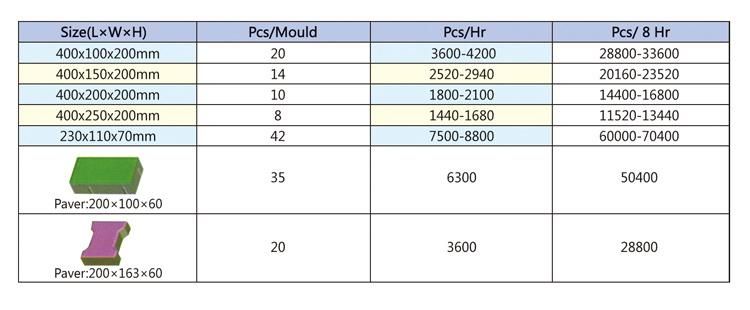

Theoretical production efficiency

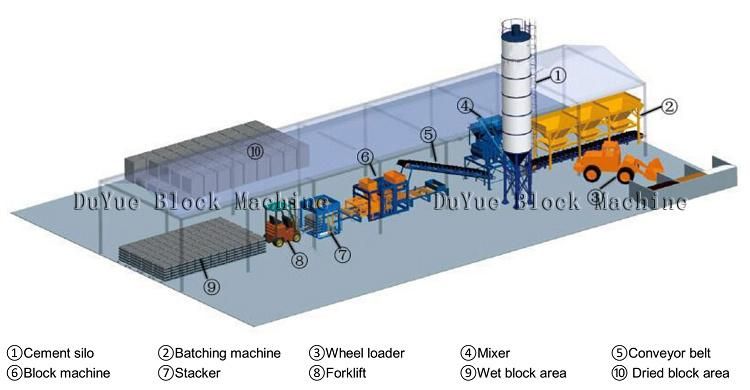

Installation site

Our service

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan.

The condition of building factory, feasibility analysis for brick machine production line).

(2) Device model choice (recommend the best machine according to the raw material, capacity

And the size of brick).

(3) 24 hours on-line service.

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation

Letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time.

(2) Quality supervision.

(3) Product acceptance.

(4) Shipping on time.

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate.

(3) offer training to the operator until they are satisfied at clients side.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other.

Duyue Industry Co.,LTD