Plastic PVC PP PE Prifles Making Extrusion Line Making Machine

Qingdao Suke Machinery Co., Ltd.- After-sales Service:24hours

- Warranty:12 Monthes

- Product Type:Extrusion Molding Machine

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Double-Screw

Base Info

- Model NO.:SJ65

- Certification:CE, ISO

- Condition:New

- Customized:Customized

- Engagement System:Full Intermeshing

- Screw Channel Structure:Deep Screw

- Type:Sheet Extruder

- Screw:Twin-Screw

- Automation:Automatic

- Computerized:Computerized

- Plastic Processed:PVC

- Feeding Mode:One Feed

- Assembly Structure:Integral Type Extruder

- Exhaust:Exhaust

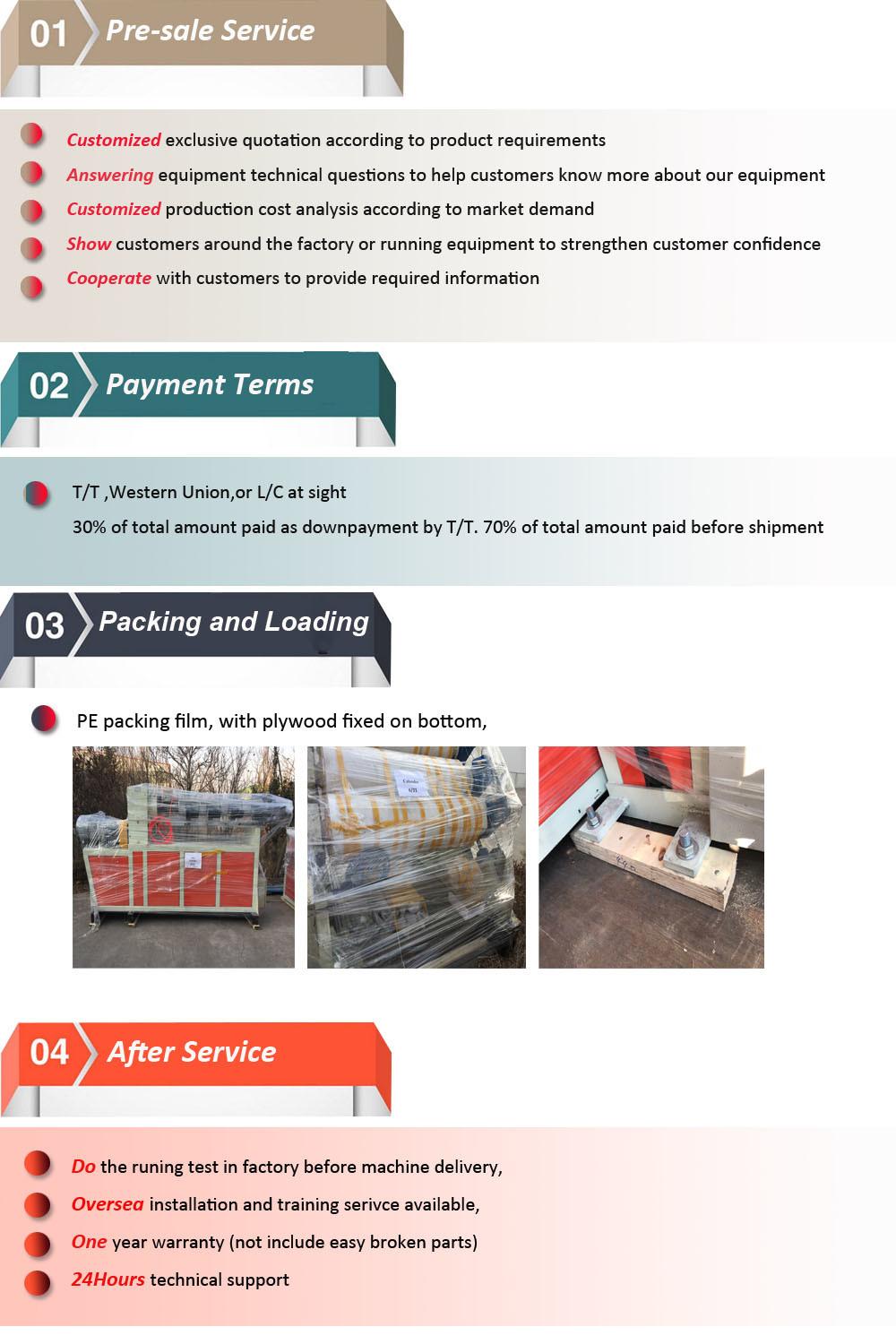

- Transport Package:According to Your Requirement

- Specification:ISO9000 CE

- Trademark:SUKE

- Origin:Qingdao, China

- HS Code:84775900

- Production Capacity:40pics,Year

Description

Basic Info.

Model NO. SJ65 Certification CE, ISO Condition New Customized Customized Engagement System Full Intermeshing Screw Channel Structure Deep Screw Type Sheet Extruder Screw Twin-Screw Automation Automatic Computerized Computerized Plastic Processed PVC Feeding Mode One Feed Assembly Structure Integral Type Extruder Exhaust Exhaust Transport Package According to Your Requirement Specification ISO9000 CE Trademark SUKE Origin Qingdao, China HS Code 84775900 Production Capacity 40pics/YearProduct Description

WPC/PE/PVC Wood Plastic Decking Board Plank Production Extrusion Line

Description:

Many wood plastic (WPC) profile/Board widely Used for city construction and outdoor Layout, Such as WPC decking board, WPC floor, WPC plank etc.

Excellent feature of WPC Decking board and plank

A) Having natural wood look and with less timber flaws

B) Moisture / water resistant

C) Resistant to acid or alkali

D) High capacity of UV-resistance and fading-resistance

E) Rotproof and moldy-proof

F) Resistant to termites and insects

G) Durable, anti-impact, wearproof, no cracking, no warping

H) Weather resistant, remaining intact under temperature range from -40

To 60

I) 100% recycled, environmental friendly, saving forest resource

J) Requiring no painting, no glue, and low maintenance

K) More flexible, easy to install and clean

L) Broad range of finishes and appearancem) Suitable for any wood Processing tools, and hot working

Equipment List:

1. Double Screw Extruder

2. Mould

3. Calibration Platform

4. Haul-off Machine

5. Cutting Machine

6. Stacker