Steel Stud and Track C Purlin Cold Roll Forming Machine Manufacturer From China Supplier

Cangzhou Nexus Machinery Co., Ltd.- Warranty:1 Year

- Certification:CE, ISO9001

- Customized:Customized

- Condition:New

- Control Type:Electric

- Automatic Grade:Automatic

Base Info

- Product Name:Steel Stud and Track C Purlin Machine

- Coil Material Thickness:0.3-0.8mm

- Processing Material:Galvanized Steel

- Roller Material:Cr12MOV

- Formingspeed:About 8-25m,Min

- Main Motor Power:5.5kw

- Hydraulic Station Power:2.2kw

- Machines Size:About 3.8m*1.5m*1.4m

- Number of Work Stations:12stations

- Max Roll Shaft of Diameter:76mm

- Transport Package:1.Control Box and Easy Damaged Parts:Protective PA

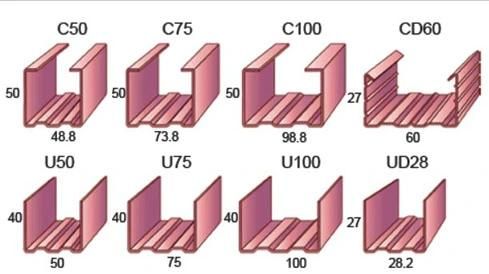

- Specification:50-150

- Trademark:Nexus Machinery

- Origin:Cangzhou

- HS Code:8455221000

- Production Capacity:10

Description

Basic Info.

Product Name Steel Stud and Track C Purlin Machine Coil Material Thickness 0.3-0.8mm Processing Material Galvanized Steel Roller Material Cr12MOV Formingspeed About 8-25m/Min Main Motor Power 5.5kw Hydraulic Station Power 2.2kw Machines Size About 3.8m*1.5m*1.4m Number of Work Stations 12stations Max Roll Shaft of Diameter 76mm Transport Package 1.Control Box and Easy Damaged Parts:Protective PA Specification 50-150 Trademark Nexus Machinery Origin Cangzhou HS Code 8455221000 Production Capacity 10Product Description

Steel Stud And Track C Purlin Cold Roll Forming Machine Manufacturer From China Supplier

l Parameters:

♥Suitable material: color steel sheet or galvanized steel sheet

♥Thickness of raw material: 0.3-0.8mm

♥Yield strength of material: 235Mpa-345Mpa

♥Forming speed: about 8-25m/min

♥Power Requirement :

Main motor power: 5.5Kw (Depend on final design)

Hydraulic station power: 2.2Kw (Depend on final design)

♥Uncoilers loading capacity Max. Capacity: 3000kgs (can be increased to be 10T)

♥Controlling system: Mitsubishi PLC & Converter

♥Machines weight: about 3-4T for different profile machine.

♥Machines size: about 3.8m×1.5m× 1.4m (Depend on final design)

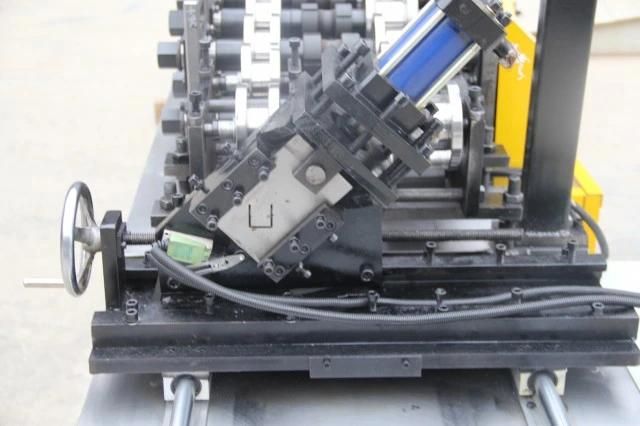

2.Material of Main Equipment:

♥Roller Material:High grade No.45 forged steel, with digital-controlled procession,

Plated with hard chrome.

♥Active Shaft Material: High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaft. Shaft diameter is 50mm.

♥Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements from famous suppliers in China

♥Cutter blade and punch dies: Cr12 mould steel with quenched treatment

- Number of Work Stations..........................12stations

- Max. Roll shaft of Diameter..........................76mm

- Overall L x W x H (Approx.)...............3.8M*1.2M*1.6M

- Roller material: GCR15 quenched 58°-62°,chromed

- Outside is cast iron, surface needed polish and paint. Inside is 60# forge and press metal)

- Transducer: Panasonic

- Cages.......................... use the strong steel nets

- Levelling screws on base ............with Thick metal paltes

ABOUT US:

FAQ:

1. How long the machine could be made?- Normally speaking, light gauge steel frame machine could

be made without 45 working days. If you need machines in a hurry, we can make it for you

less than a month.

2. How to visit your company?

-a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),

then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5

hours), then we can

pick up you.

3. Do you have after sales support?

-Yes, we are happy to give advice and we also have skilled technicians available across the

world.We need your machines running in order to keep your business running.