Aluminium Corrugated Iron Sheet Making Roofing Machine

Cangzhou Nexus Machinery Co., Ltd.- After-sales Service:Provide Overseas Service

- Warranty:1 Year

- Tile Type:Colored Steel

- Certification:CE, ISO

- Condition:New

- Customized:Customized

Base Info

- Model NO.:NM4261

- Usage:Roof, Wall

- Transmission Method:Electric

- Product Name:Aluminium Corrugated Iron Sheet Making Machine

- Raw Material:PPGI Sheet

- Thickness Range:0.3-0.8mm

- Machine Power:4kw+3kw

- Machine Weight:About 5 Tons

- Warrenty:12 Months

- Main Shaft Dia:70mm

- Material:45#Forge Steel and Quenched

- Roll Station:18 Groups

- Length Tolerance:1.5mm

- Transport Package:Plastic Film & Steel Wire Fixed

- Specification:6000mm*1500mm*1500mm(L*W*H)

- Trademark:NEXUS MACHINERY

- Origin:China

- HS Code:8455221000

- Production Capacity:30 Sets , Months

Description

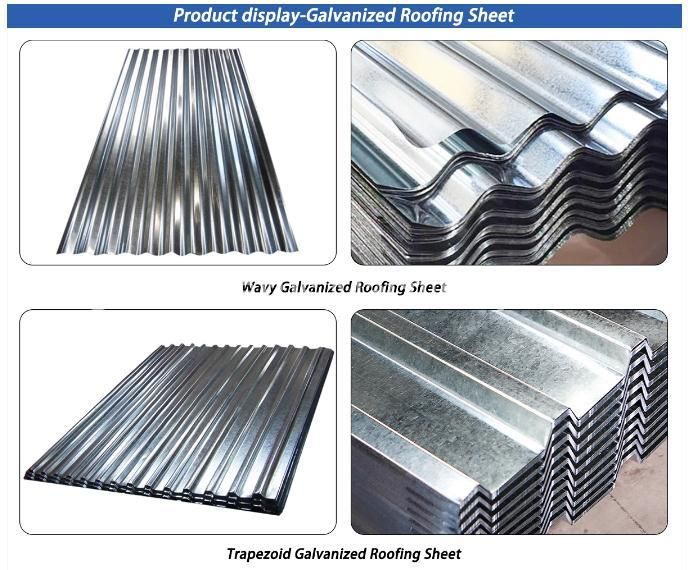

Suitable Material

Material

GI, PPGI, PPGL

Width

914 mm

Thickness

0.3-0.8 mm

Material of rollers

High grade 45# forged steel, surface hard chromium plating

Rows of rollers

18 stations

Material of shafts

High grade 45# forged steel

Diameter of shafts

70mm

Material of blade

Cr12 Heat Treatment

Cutting Mode

Hydraulic Guide Column

Speed

20-25m/min

Side plate thickness

16 mm

Chain size

1 inch

Total power

4 kw

Voltage

380V 50HZ 3Phase

Appearance size (About)

8600mm*1300mm*1500mm

Weight(About)

4.5 tons

Electronic control system

PLC (Delta) Touch Screen

| No. | Product Name | QTY |

| 1 | 5T Manual decoiler | 1 |

| 2 | Aluminium Corrugated Iron Sheet Making Roofing Machine (Includes Hydraulic cutting, PLC computer, Electrical cabinet, Hydraulic system) | 1 |

| 3 | Passive Output table | 2 |

| Sum | 4 |

5. Character of main structure:

- The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connectors are screw which make the machine flexible and stronger.

- All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

- We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

- It is very easy to install the equipment and suitable for producing in the factory.

- Low noise with high efficiency.

7. Why Choose US?

1. More than 10 years experiences in manufacturing roll forming machines.

2. We use Automatic control software to manage productive information makes the whole automatic control system has an improvement in automaticity.

3. High performance in operation, maintenance, and debugging. Easy to load and unload.

4. Good machine quality, Competitive price and Fast delivery time and superior service.