Steel Ridge Cap Roll Forming Machine Galvanized Roof Top Ridges Equipment

Cangzhou Nexus Machinery Co., Ltd.- Warranty:12 Months

- Tile Type:Colored Steel

Base Info

- Model NO.:NM1418

- Certification:CE, ISO

- Condition:New

- Customized:Customized

- Usage:Roof, Wall

- Transmission Method:Electric

- Name:Steel Ridge Cap Roll Forming Machine

- Raw Material:PPGI Sheet

- Thickness Range:0.3-0.8mm

- Machine Power:4kw+3kw

- Work Speed:8-10m,Min

- Shaft Material:45# High Grade Forge Steel ,Chrome Coated 0.05mm

- Machine Weight:About 3 Tons

- Operation Type:Touchig Screen

- Afer-Sales Service:Engineer Is Availble to Overseas

- Transport Package:Plastic Film & Steel Wire Fixed

- Specification:3500mm*500mm*700mm(L*W*H)

- Trademark:NEXUS MACHINERY

- Origin:Cangzhou, China

- HS Code:8455221000

- Production Capacity:30 Sets , Months

- Package size per unit product:650.00cm * 80.00cm * 160.00cm

- Gross weight per unit product:3000.000kg

Description

Basic Info.

Model NO. NM1418 Certification CE, ISO Condition New Customized Customized Usage Roof, Wall Transmission Method Electric Name Steel Ridge Cap Roll Forming Machine Raw Material PPGI Sheet Thickness Range 0.3-0.8mm Machine Power 4kw+3kw Work Speed 8-10m/Min Shaft Material 45# High Grade Forge Steel ,Chrome Coated 0.05mm Machine Weight About 3 Tons Operation Type Touchig Screen Afer-Sales Service Engineer Is Availble to Overseas Transport Package Plastic Film & Steel Wire Fixed Specification 3500mm*500mm*700mm(L*W*H) Trademark NEXUS MACHINERY Origin Cangzhou, China HS Code 8455221000 Production Capacity 30 Sets / MonthsPackaging & Delivery

Package size per unit product 650.00cm * 80.00cm * 160.00cm Gross weight per unit product 3000.000kgProduct Description

Steel Ridge Cap Roll Forming Machine Galvanized Roof Top Ridges EquipmentSteel Ridge Cap Roll Forming Machine Galvanized Roof Top Ridges Equipment is one most popular type of roll forming machines. It makes different shape of color steel ridge cap sheet, which is used for buildings, factory, supermarket ect. For this machine, it suit coil width is 400mm, thickness range is from 0.3mm to 0.8mm. We adopt guide pin type to make machine frame strong. Usually it can run with the max speed to 15m/min, PLC with touch screen operation make the machine simple and easy for usage.

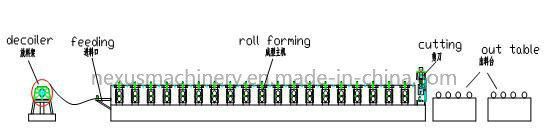

1. Processing flow diagram of machine:

Decoiler→ Feeding →Roll forming →Measure length →Hydraulic cutting →Output table

2. Profile Drawings for Reference:

3. Technical parameters:

NO. | Item | Specification |

1 | Processing material | PPGI, GI Steel |

2 | Processing thickness | 0.2-0.8mm |

3. | Coil width | 500mm |

4. | cover width | 312mm |

5. | Material of main frame | 300H steel |

| 6. | Diameter of Soild shaft | 70mm, high grade 45# steel |

| 7. | Roller | Quenched and tempered treatment,hard chrome coated 0.05-0.07mm |

| 8. | Thickness of middle plate | 16mm |

| 9. | Forming station | 16 station |

10. | Transmission | By chain(1.0 inch) link bearing model 6210 |

11 | Power of main motor | 5.5kw with Cycloidal reducer |

12 | Power of pump station | 4kw |

13 | Forming speed | about 8-10m/min |

| 14 | Hydraulic cutting | Controlled by PLC |

| 15 | PLC | DELTA(TAIWAN)/Mitsubishi |

| 16 | Material of razor blades | Cr 12, quenching 58-62ºC |

| 17 | Frequency converter | It has the advantage of slowing down before cutting, to ensure the length accuracy(±1mm, far better than industrial standard ±3mm). |

| 18 | Switch | CHNT |

| 19 | Transducer | SAJ |

4. Equipment list :

| No. | Product Name | QTY |

| 1 | 5T Manual decoiler | 1 |

| 2 | Steel Ridge Cap Roll Forming Machine Galvanized Roof Top Ridges Equipment (Includes Hydraulic cutting, PLC computer, Electrical cabinet, Hydraulic system) | 1 |

| 3 | Passive Output table | 2 |

| Sum | 4 |

5. Guarantee:

1) Engineer will give free training lessons to labors in buyer's factory.

2) The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for engineer.

3) During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, we will provide the buyer spare parts at cost price.

4). We will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

6. Photos of Steel Ridge Cap Roll Forming Machine Galvanized Roof Top Ridges Equipment for Reference:

ABOUT US:

Cangzhou Nexus Machinery Co.,Ltd is experienced manufacturer & exporter of cold roll forming machine with ISO quality system.

Our R&D department is staffed with senior engineers who has more than 20 years experience in metal forming machine industry, so we are able to assist customers with professional designing and solution.

Our range of products: roof tile roll forming machine, cladding roll forming machine, metal decking roll forming machines, C/U/Z/W/L steel purlin roll forming machine etc. We also can supply steel coils, roof panels to suit diverse requirements of our global customers.

Today, we have exported our machines to America, Chile, Mexico, Bolivia, Brazil, Colombia, Argentina, Ecuador, Honduras, Fiji, Papua New Guinea, Kuwait, Syria, Oman, Saudi Arabia, U.A.E, Nigeria, Tanzania,Ethiopia, Gana, Guinea,South Sudan, Algeria, Niger, Philippines,Indonesia,India, Azerbaijan and Kazakhstan.

We have rich experience for cold roll forming machine solution,competitive price and excellent service. We will continue to do our best to supply perfect products and service for customers. Invite you to contact us for further information.

Hot-Sale Products you Might Be Interesting:

Packing:

1. One 20feet container for loading one set machine with mechanical decoiler.

2. Main machine body and decoiler is load naked (tighten to container with steel wire rope).

3. Spare parts and operating tools are loading in tooling box.