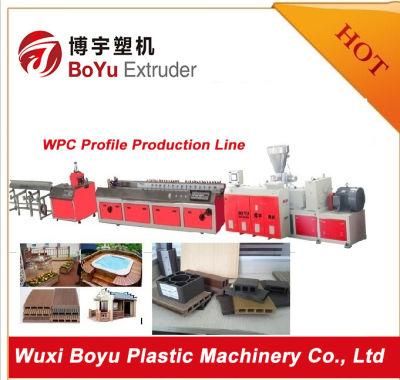

Wood Plastic Composite Door Board Production Line

Wuxi Boyu Plastic Machinery Co., Ltd.- Type:Sheet Extruder

- Plastic Processed:PVC

- Feeding Mode:One Feed

- Assembly Structure:Separate Type Extruder

- Screw:Twin-Screw

- Engagement System:Intermeshing

Base Info

- Model NO.:BYSJ

- Screw Channel Structure:Deep Screw

- Exhaust:Exhaust

- Automation:Automatic

- Computerized:Computerized

- Transport Package:PVC Film

- Specification:CE SGS

- Trademark:BOYU

- Origin:Wuxi

- HS Code:8477209000

- Production Capacity:30 Lines ,Month

Description

Item

Characteristic:

1.The extruder and the extractor adopt the imported AC frequency control device ,the unique screw design ensures the high efficiency extrusion of PVC material, flexible plasticizing, and high output

2. Advanced control system ensures the smooth running

3.Die: innovative spiral flowing structure avoids fuse mark appearance on the bigger pipe , profile of ideal dwell time is full of the whole flow cross-section. Homogeneous melt distribution with selective temperature control guarantees outstanding product characteristics for PVC materials

If you are interested ,please contact with me for more details.

Main Technical Parameter:

Description

Parameter

Feed material

PVC+ wood powder+assistant materials

Product size

600mm×35mm×1900mm(the length adjustable)

Production line speed

0.8-1m/min

Max. output

500kg/h

Outline size

23×2.5×3 L×W×H(m),unsaturated

Weight

16T

Total power

255kw

Actual energy consumption power

210kw

Consumed air

0.4m3/min

Atmospheric pressure

0.6mpa

Water cycle

0.3m3/min

Power

AC380V±10%,50HZ

Water

Industrial water, no impurity, with filtration treatment, pressure: 0.4Mpa temperature: 14-25°C

Work environment temperature

0-40°C

To provide information and market research,to provide consultation,to provide many kinds of conveniences and market service,etc. Products: PVC Foam Board Machine...

The main purpose of pre-sales service is to help customers make the project planning and system requirements analysis. Make our products maximum to meet clients' requirements. Also play the greatest overall economic benefits of customers' investment.

After-sale service:

To install products and test products freely for customers.

To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

To direct technology aspect of relevant use according to customers' requirements

To provide technical training for clients' employees.

To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Technology support:

To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information of chemical material manufactories.

To provide technical training for clients' employees.