Hr1-10 Full Automatic Brick Machine Clay Building Material Brick Making Machine

SHANDONG HENRY INTELLIGENT MACHINERY MANUFACTURING CO., LTD.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydraulic Shock

- Model:Hr1-10

- Electricity Source:380V,50Hz(Adjustable )

Base Info

- Model NO.:HR1-10

- Rated Pressure:16-25MPa

- Overal Size:1000*100*1800mm

- Rated Power:5.5kw or 15 Hpdiesel Engine

- Molding Cycle:6-10s

- Cooling Way:Water Cooling

- Weight of Machine:1000kg

- Capacity:4000-4800pieces (8 Hours )

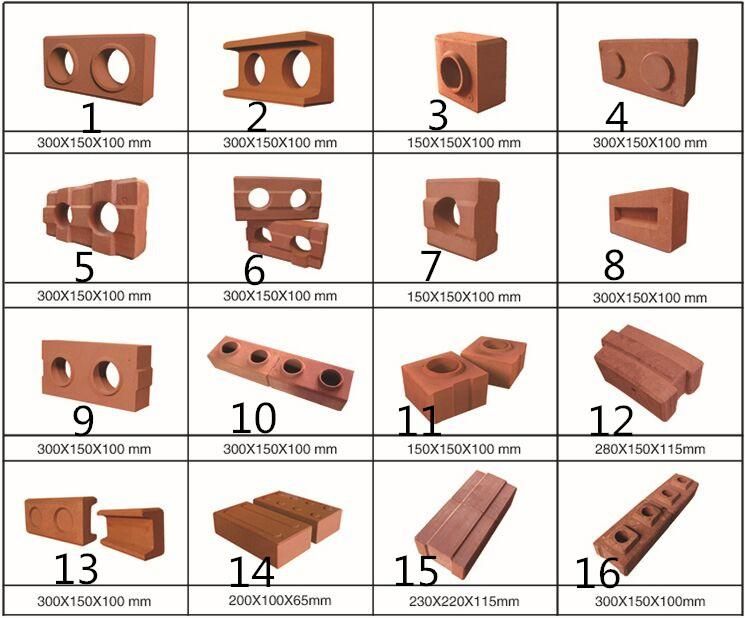

- Moulds:Changeable

- Transport Package:Wooden or Container

- Specification:1000*1000*1800mm

- Trademark:Henry

- Origin:China

- HS Code:8474802000

- Production Capacity:50 Pieces ,Month

Description

The advantages of our soil building materail brick making machine HR1-10

1.With 15cm diameter hydraulic cylinder,Processing shift short,high efficiency and higher pressure.

2.Surrounding style protective screening,Avoid concrete pellets from hopper hurt workers.

3.Hydraulic oil meter.With this,it is easy to adjust rated pressure,for different brick pressure requirement.

4.Brick molding.With screw to be connected in order to change molding more easierly.

5.Discharging system with Intelligence sensor.Discharging is more Accurate and uniform.

Brick capacity

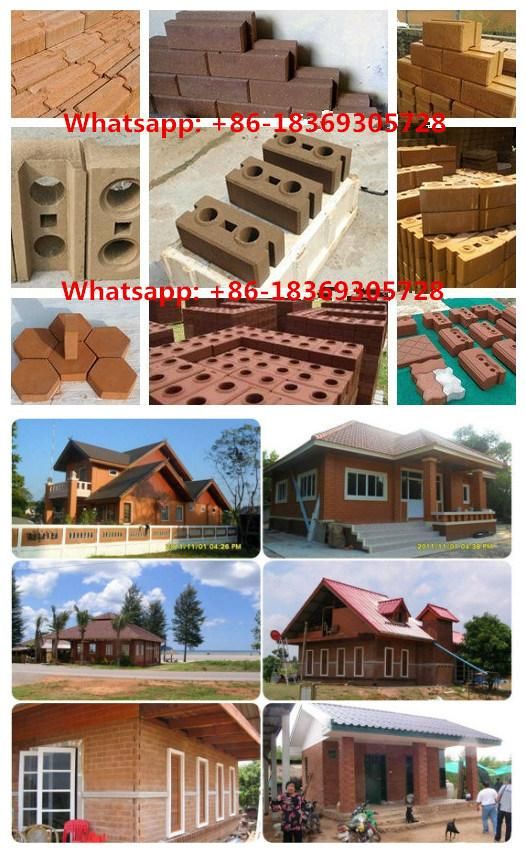

Bricks and building construction views

About us

Company profile

Henry Industrial Co., Ltd has been committed to designer, manufacturer, saler of construction machinery,has the domestic advanced equipments, super professional skills. With over 23 years of experience, we produce a wide range of products like hollow block machine, soil brick machine, interlocking brick machine, paving machine, crusher, mixer, block mould and paving mould.

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation

letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at clients side.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other

If you have any need about our soil building material brick making machine,please contact us