Thermal Break Assembly Machine (three steps) at Best Price

Shandong Truetec Machinery Co., Ltd.- Condition:New

- Certification:ISO, CE

- CNC or Not:not CNC

- Voltage:380V

- Product Name:Thermal Break Assembly Machine (Three Steps) at Be

- Input Power:4kw

Base Info

- Model NO.:GYJ-01

- Feeding Speed:0-90m,Min (Stepless Adjusting)

- Rolling Disc Diameter:210mm

- Coaxial Rolling Discs Distance:0-80mm

- Front and Back Rolling Discs Distance:0-100mm

- Max. Profile Processing Section:250*250mm (W*H)

- Profile Support Dimension:5000*450*1100mm (L*W*H)

- Color:as Requirement

- Keyword:Thermal Break Rolling Machines

- Transport Package:Simple Stretch Film or Professional Export Plywood

- Trademark:TRUETEC

- Origin:Shandong China

- Production Capacity:15 Sets Per Month

Description

Basic Info.

Model NO. GYJ-01 Feeding Speed 0-90m/Min (Stepless Adjusting) Rolling Disc Diameter 210mm Coaxial Rolling Discs Distance 0-80mm Front and Back Rolling Discs Distance 0-100mm Max. Profile Processing Section 250*250mm (W*H) Profile Support Dimension 5000*450*1100mm (L*W*H) Color as Requirement Keyword Thermal Break Rolling Machines Transport Package Simple Stretch Film or Professional Export Plywood Trademark TRUETEC Origin Shandong China Production Capacity 15 Sets Per MonthProduct Description

Thermal break assembly machine (three steps) at best price Product Application

Product ApplicationThis aluminum profile rolling machine is to combine thermal barrier strip or plastic profile with aluminum profiles to make the end product, which is called bridge-cut-off aluminum alloy profile or thermal break aluminum profile. Hardened rollers are used to press the knurled profile and thermal barrier strip or plastic profile together, to make a composite profile that has great insulation effect.

Main Features

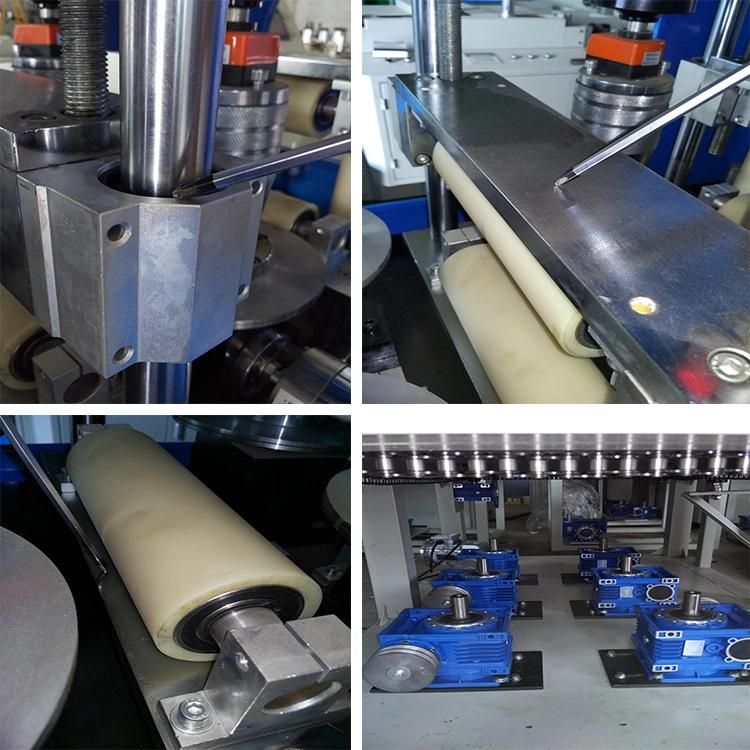

1. Equipped with three groups of hardened rollers electrically controlled, available in changing profiles quickly with the Nylon rollers. Two-axis direction adjustments.

2. Six rollers controlled by separate driving force guarantee stable rolling, higher speed, and higher efficiency

3. Space between roller wheelings adjustable. Suitable for various sizes of thermal barrier strips.

4. Frequency converter with stepless speed regulation.

5. High-precision screw are used for driving.

Technical Data

| Input power | 4Kw |

| Power supply | 380V 50Hz |

| Air pressure | 0.5~0.8MPa |

| Feeding speed | 0-90m/min (stepless adjusting) |

| Rolling disc diameter | 210mm |

| Coaxial rolling discs distance | 0-80mm |

| Front and back rolling discs distance | 0-100mm |

| Max. profile processing section | 250*250mm (W*H) |

| Profile support dimension (L*W*H) | 5000*450*1100mm |

| Overall Dimension | 1300*1100*1700mm (L*W*H) |

| Weight | 2000kg |

Machines Details

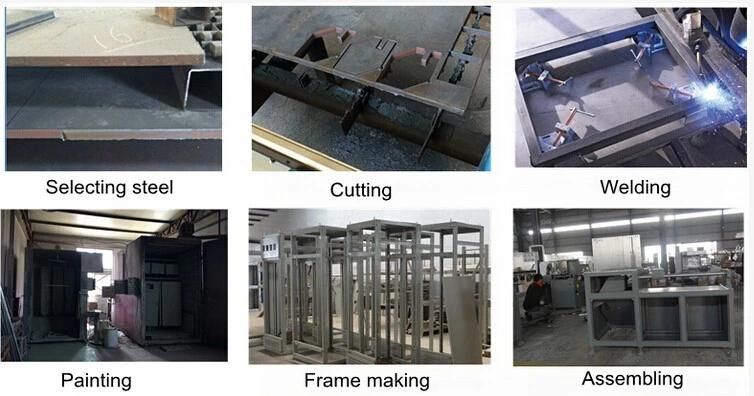

Machine processing

We work with everything from raw material to final machine, could guarantee machine quality from each step. select each part carefully, we are strive to quality first when machine production and test each machine before delivery.

We will provide the best machine for you.

Packaging&Shipping

Our Company

Welcome To Visit

Our company is a manufacturer of window machine, insulating glass processing machine and curtain wall machine with well-equipped testing equipment and strong technical force.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in building trade and other industries. Hope we can cooperate with you.

Our Exhibition

Our Services

Before payment

Free contact for the most suitable machine

Free professional design for each customer especially.

After sale service

24 hours technical support by phone, email or skype (email or skype) .

1years warranty period

Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

By offering this support, we make sure the cutomer start the business smoothly, to realise win-win cooperation.

Payment

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union or Paypal.

FAQ

1. When can we arrange shippment?

We usually arrange shippment within 25 days after getting deopsit,

but customized machines should be more than 25 days.

2.What you can do if my machines have problems?

1) We can send you free components to you if your machines are in guarantee time.

2) We can send our engineers to repair your machines

3.Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.