5% Fully Automatic Qt8-15 High Hydraulic Pressure Concrete Block Making Machine Cement Brick Whole Production Machine in Tanzania Bangladesh Philippines R. D

SHANDONG HENRY INTELLIGENT MACHINERY MANUFACTURING CO., LTD.- Warranty:3 Years

- Certification:CE, ISO

Base Info

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydraulic Shock

- Pallet Size:1300*900*30mm

- Dimension:3500*2300*2930mm

- Molding Area:1196*880mm

- Moldels of Mixer:Js750

- Viberation Force:100kn

- Transport Package:Nude Package for Full Container

- Specification:9.8T

- Trademark:HENRY

- Origin:Shangdong China

- HS Code:8474802000

- Production Capacity:2100PCS,Hour

- Package size per unit product:5300.00cm * 1700.00cm * 2700.00cm

- Gross weight per unit product:9000.000kg

Description

Basic Info.

Customized Customized Automatic Grade Automatic Type Hydraulic Shock Pallet Size 1300*900*30mm Dimension 3500*2300*2930mm Molding Area 1196*880mm Moldels of Mixer Js750 Viberation Force 100kn Transport Package Nude Package for Full Container Specification 9.8T Trademark HENRY Origin Shangdong China HS Code 8474802000 Production Capacity 2100PCS/HourPackaging & Delivery

Package size per unit product 5300.00cm * 1700.00cm * 2700.00cm Gross weight per unit product 9000.000kgProduct Description

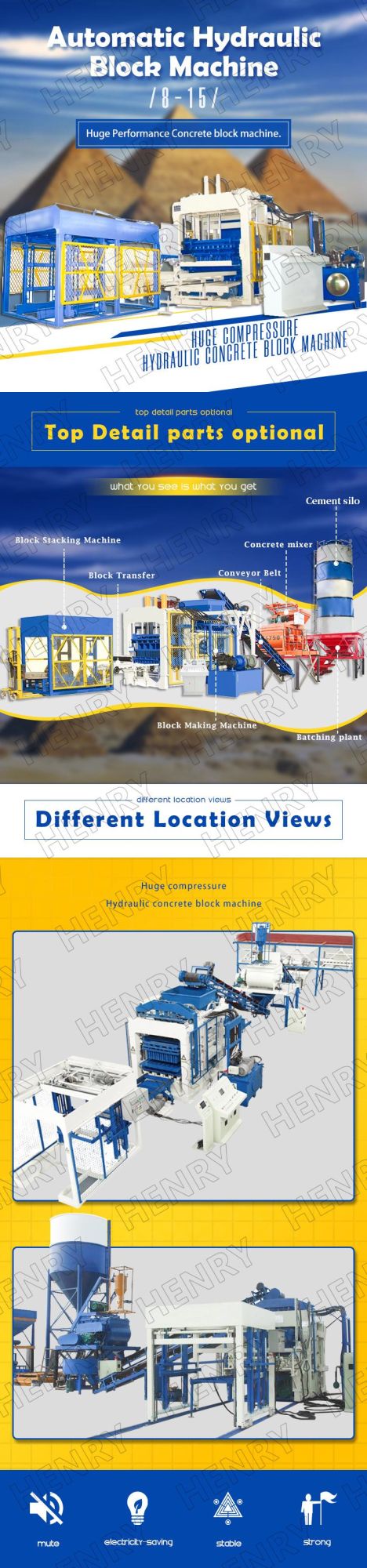

Fully automatic QT8-15 Hydraulic Concrete Widely Used /Block Making Machine Cement Brick Machine Whole Production Line. There is high hydraulic pressure for very perfect performance .

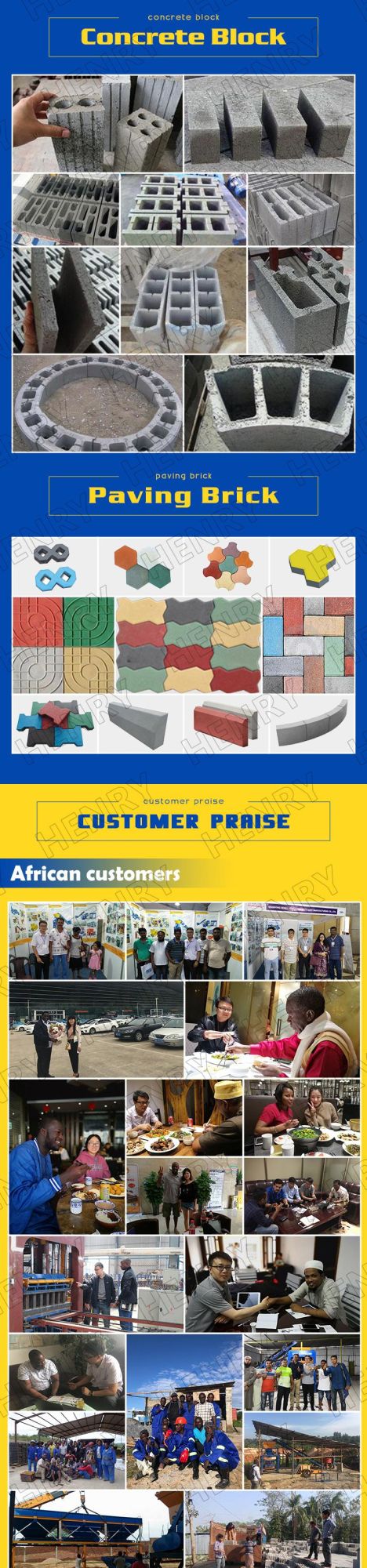

Qt8-15 Hydraulic Cement Brick Making Machine Curbstone Widely Used Block Making MachineIt can produce hollow blocks/bricks , pavers and curbstones by changing moulds and there will be very good pressure performance for big curbstones . There will be working video for you to well know our machine once you need .

1. Henry QT8-15 automatic concrete interlocking block brick making machine can produce various solid blocks , hollow blocks, pavers and curbstones by changing moulds.

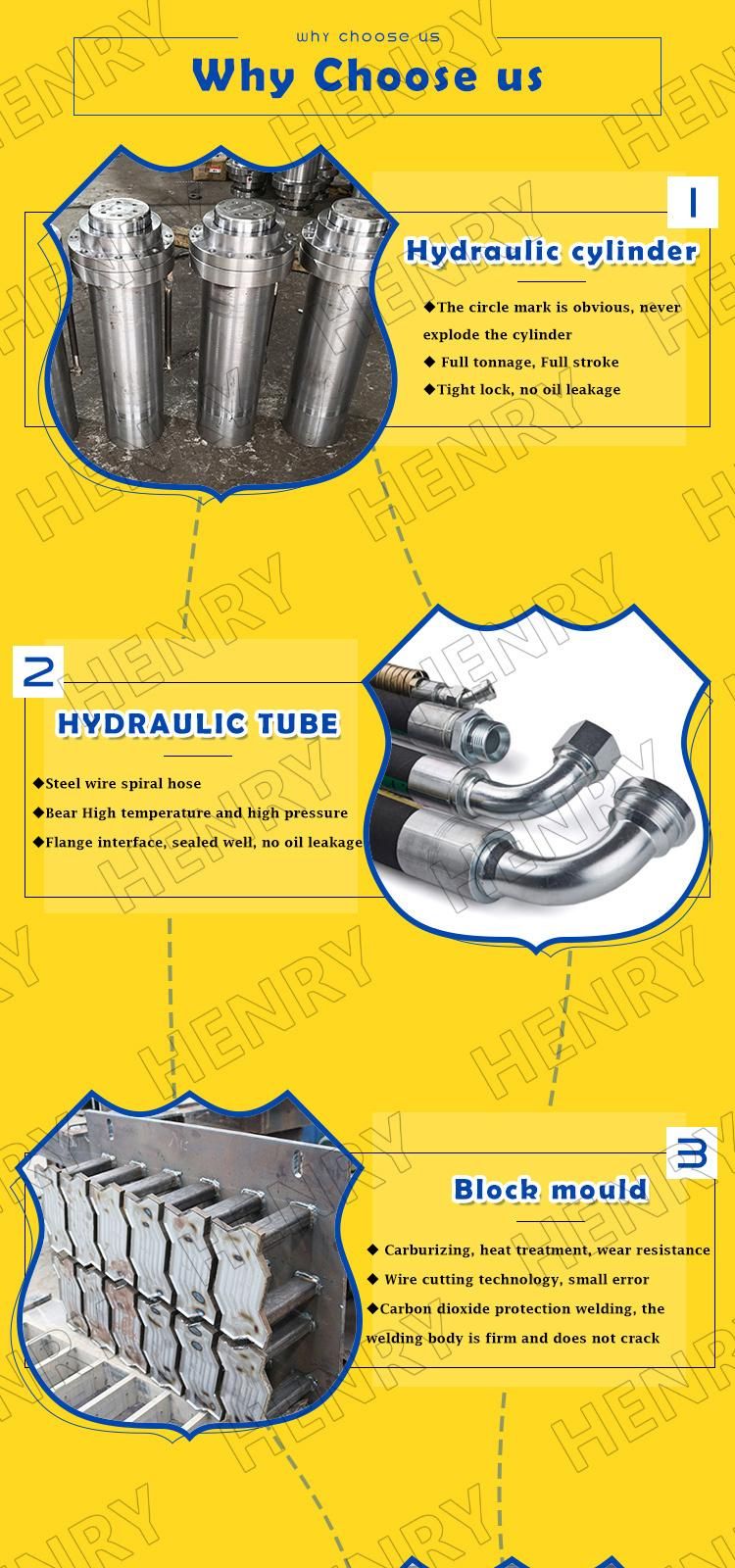

2. Henry QT8-15 automatic concrete interlocking block brick making machine adopt to hydraulic pressure moulding system , so the brick machine has more stable and higher-efficiency working status and the bricks produced are of better quality, larger density and higher strength.3. Precise line cutting technology and carburizing treatment technology to prolong mould life and increase precision of the block.

4. Switches will use Japan Omron or France Schnider band, motor will use Siemens or ABB brand as different request of clients

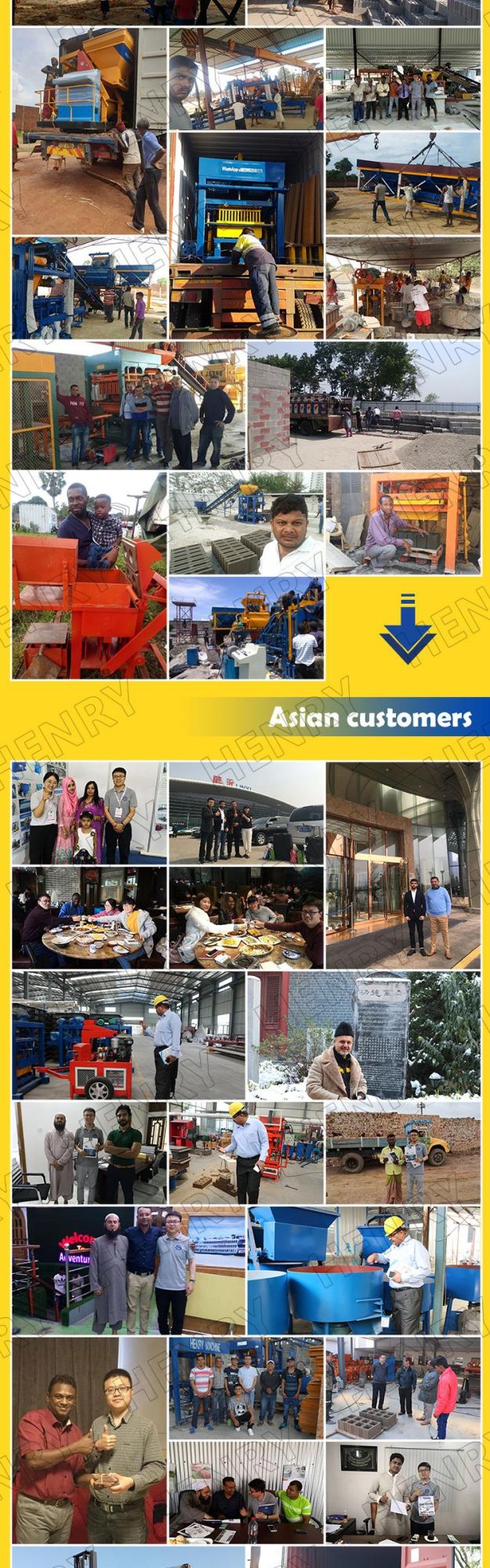

CONTACT INFORMATION

CONTACT INFORMATIONMary Tang