Popular Roll Forming Machine Shutter Door Tile Roll Forming Machine Door Frame Machine

HEBEI XINNUO ROLL FORMING MACHINE CO., LTD.- Condition:New

- Certification:ISO, CE, SGS, as You Like

- Color:as You Like

- Trade or Factory:Factory

- Guarantee:1 Year

- Life Time:10 Years

Base Info

- Service:Provide Engineer to Install The Machines

- Brand Name of PLC:as Customer Request

- Drawing:Designed as Customer Request

- Power:38V, 50Hz, 3 Phrase or as Your Like

- Decoiler Type:Manul, Electric, Hydraulic

- Control System:PLC

- Tile Type:Colored Steel

- Customized:Customized

- Usage:Roof, Wall, Roller Shutter Door

- Transmission Method:Electric

- Transport Package:Main Machine Nude Packing with Plastic Film

- Specification:5800*1500*1500

- Trademark:KXD

- Origin:China

- HS Code:8455221000

- Production Capacity:30 Sets Per Month

Description

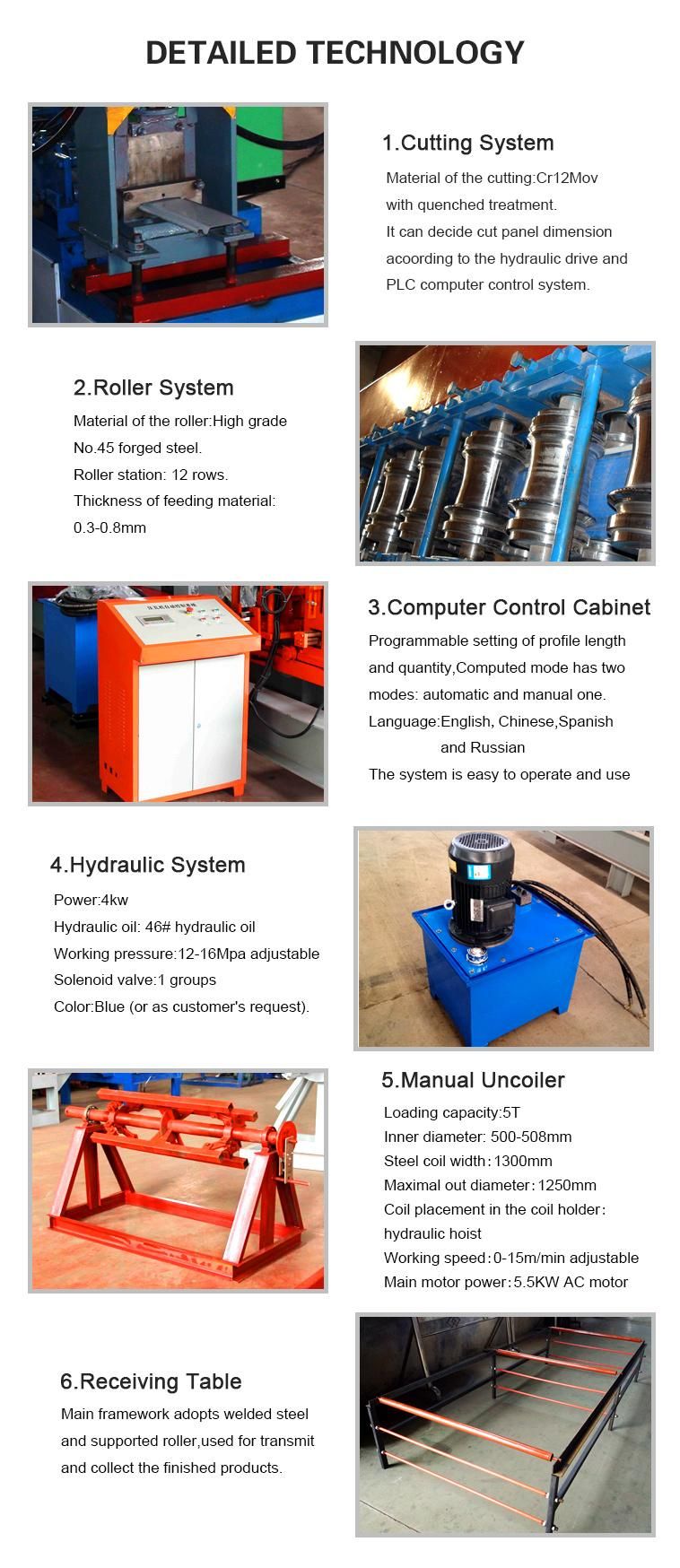

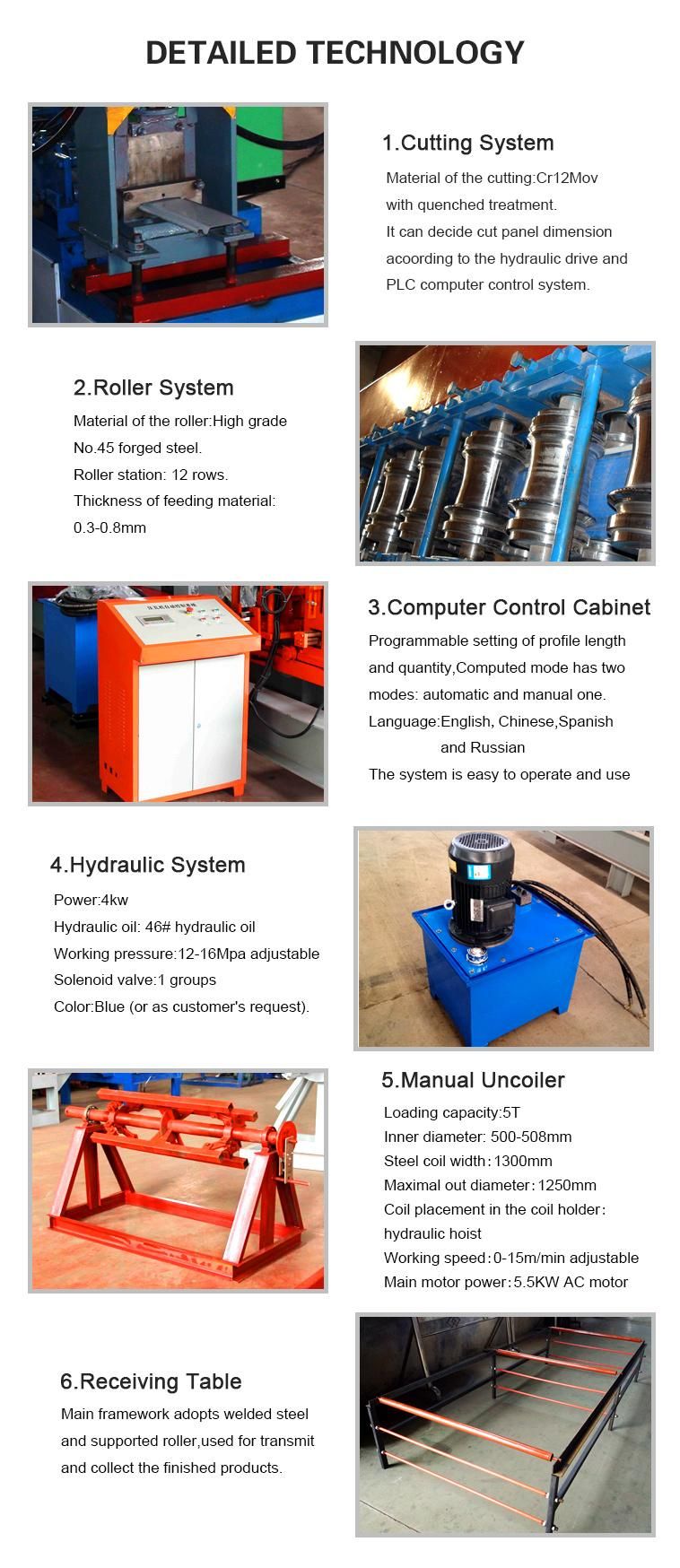

Technical parameters:1 Name of commodity & specification roller shutter door roll forming machine 2 Main motor power 3kw, 3 phase 3 Hydraulic motor power 3kw 4 Hydraulic Pressure 10-12MPa 5 Voltage 380V /3phase/ 50 HZ (or as your requirement) 6 Control System PLC Delta Inverter 7 Main Frame 300mm H-Beam 8 Backboard Thickness 14mm 9 Chain Size 20mm 10 Feeding Material color steel coils 11 Feeding Thickness 0.3-0.8mm 12 Productivity 8-12m/min 13 Roll Station 11 14 Roller Diameter 52mm 15 Roller material 45# steel 16 Cutter material Cr12 , quenched 17 Cr-Plating Size 0.05mm 18 Overall Size 3000×800×1000mm 19 Total Weight 2T 20 Components Manual Uncoiler-------------------1 set

Guiding Platform------------------1 set

Coil Strip Leveler------------------1 set

Main Machine of Roll Forming------1 set

Electric-Motor---------------------1 set

Cutting Device--------------------1 set

Hydraulic Station------------------1 set

PLC Control-----------------------1 set

Supporter Table-------------------1 set

Equipment components: Manual uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting, run out table

2.the picture of the roller shutter door roll forming machine

3.The production process

Decoiler→Flating→Feeding →Forming→Cut to length→Colletion---(finish goods)

4.Production Flow

5.Packaging & Shipping

Main machine is nude, the computer control box is packed with wooden frame

6.company overview

7.FAQ

1:How to play order: Inquiry---confirm the profile drawings and price----confirm the PI---arrange the deposit or L/C---then OK

2:How to visit our company:

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3:When we exported the machines:

We have beening making and exporting the machines since from the year of 1998.

4:If you want to get more pictures or videos of the machines,I can send them to you by Email or SKype.

8.Contact information

CONTACT PERSON:helen wang

Guiding Platform------------------1 set

Coil Strip Leveler------------------1 set

Main Machine of Roll Forming------1 set

Electric-Motor---------------------1 set

Cutting Device--------------------1 set

Hydraulic Station------------------1 set

PLC Control-----------------------1 set

Supporter Table-------------------1 set

Equipment components: Manual uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting, run out table

2.the picture of the roller shutter door roll forming machine

3.The production process

Decoiler→Flating→Feeding →Forming→Cut to length→Colletion---(finish goods)

4.Production Flow

5.Packaging & Shipping

Main machine is nude, the computer control box is packed with wooden frame

6.company overview

7.FAQ

1:How to play order: Inquiry---confirm the profile drawings and price----confirm the PI---arrange the deposit or L/C---then OK

2:How to visit our company:

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

3:When we exported the machines:

We have beening making and exporting the machines since from the year of 1998.

4:If you want to get more pictures or videos of the machines,I can send them to you by Email or SKype.

8.Contact information

CONTACT PERSON:helen wang