Hr2-25 Small Investment Diesel Soil Brick Machine

SHANDONG HENRY INTELLIGENT MACHINERY MANUFACTURING CO., LTD.- After-sales Service:24-Hours

- Warranty:3 Years

- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydroforming

Base Info

- Model NO.:HR2-25

- Colour:According to Your Demand

- Motor:Semins

- Mold:Changeable

- Brick Raw Material:Coal Cangue, Clay, Cement, Soil

- After-Sales Service Provided:Engineers Available to Service Machinery Overseas

- Transport Package:Iron Box or Wood Box with Angle Iron Frame

- Specification:CE SGS ISO

- Trademark:HENRY

- Origin:China(Mainland) Shandong Linyi

- HS Code:8474802000

- Production Capacity:150 PCS 250X125X100mm , Per Hour

Description

Basic Info.

Model NO. HR2-25 Colour According to Your Demand Motor Semins Mold Changeable Brick Raw Material Coal Cangue, Clay, Cement, Soil After-Sales Service Provided Engineers Available to Service Machinery Overseas Transport Package Iron Box or Wood Box with Angle Iron Frame Specification CE SGS ISO Trademark HENRY Origin China(Mainland) Shandong Linyi HS Code 8474802000 Production Capacity 150 PCS 250X125X100mm / Per HourProduct Description

The detail of HR2-25 clay soil interlocking brick making machineHydraulic soil block machine is our newest clay and cement brick

making machine. It is automatic operation machine .its material feeding .mould pressing and mould lifting automatically .

You can chose diesel engine or motor.

Specifications:

*Block making machines manufactures

*Brick machinery

*Strong structure,work steady durable

*Easily operate

Advantages:

HR2-25 block machine:

1)Material hopper.It can reserve 8-10 shift material.Saving feeding time.

2)Diesel or electric engine power.We use the world famous brand,CHANGCHAI engine

3)Hydraulic oil meter.Easy to show pressure timely.

4)Molding cover.Simple operation,processing accurate,durable

5)Surrounding style protective screening.Avoid concrete pellets from hopper

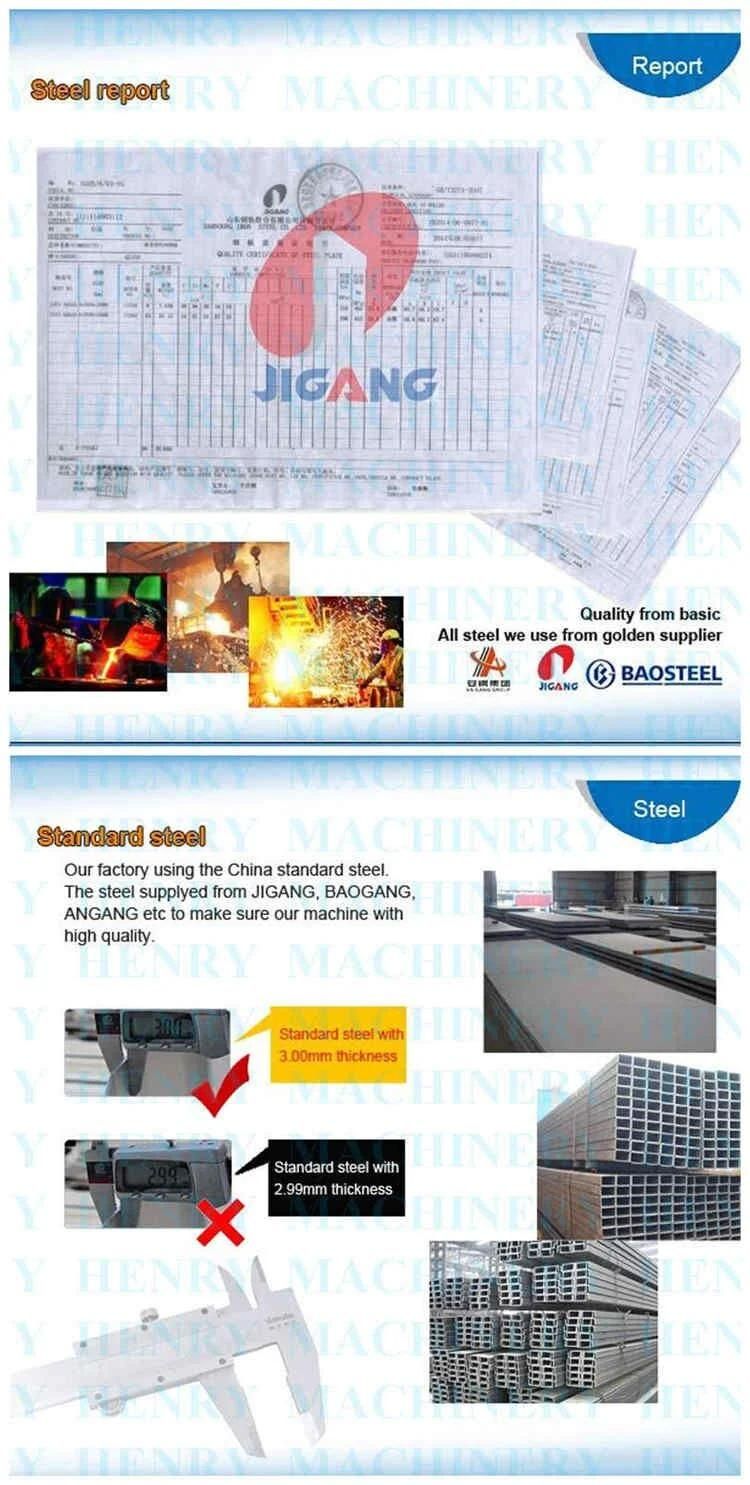

6)Steel raw material.Using 45# steel that is 3 times harder than our company

7)Molding.Molding with Carburizing technology,solid and more durable

The block sample of HR2-25 clay soil interlocking brick making machine

company file

Guarantee

(1)We can supply one year guarantee period for our brick making machines,if the client have the question ,they could call

our service department number any time , we will supply per day 24 hours service .

(2)Within one year ,if the client meet the unsolvable questions ,we could fly to client place to help.

Our service

we have go big after sale service team , they are all the experience technician,

over 20 workers have the passport ,they all have the oversea experience.

So we not only have good service in the pre service , we also think highly of the

after sale service.

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation

letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other

ASK HERE

What is the soil type for ecological brick fabrication?

The more appropriated soil is that which indicates of 50% to 70% sandy. However today, with the technologies, the soil that don't have this feature can be corrected, with other material, guaranteeing an great brick.

What are the cement types that can I use?

For the production of ecological bricks and floors haven't restriction for the cement type to be used, because all develop the same function of give resistance to the brick, so the choice is up to the customer.

Must be done a special foundation for the construction of ecological brick?

No. It is a foundation equal to the construction that use the conventional brick and in both cases, changes according to project and the soil of region.

How many paving can be done using ecological bricks?

The quantity of floors change according to every project study, this quantity must be indicated by calculating of project that will take into account facts like foundation type to be used, loads that this building will have, etc. We have in our project gallery, a housing conjunct in the city of Ourinhos-SP, that have more of 70 houses, being the blocks in 3 paving. Check the photos in our site.

The ecological brick can only be seated with glue?

No, the ecological brick can be seated in many ways, the glue PVA is one of the ways more practice and faster, we can use conventional bedding mortar or a mixing made of glue, water and de own soil too. By a modular system, depending of proposed project, we can dispense the glue between the bricks for to use only the system of fitting of them.

Allen

Cell phone:+86 18369325716