Fireproof High Automatic Magnesium Oxide Board Machine

OYADE (Shandong) Machinery Equipment Co., Ltd.- Warranty:1year

- Product Type:MGO Board

- Automatic Grade:Automatic

- Power Source:Electric

- Screw Design:Double-Screw

- Certification:CE, ISO

Base Info

- Model NO.:MGO-C-20190902

- Condition:New

- Customized:Customized

- Capacity:Max 4000pieces,Shift, Adjustable

- Site Area:≥5000sqm, High≥7m

- Board Type:Sanding MGO Board, Sulfate MGO Board

- The Mixer:Double Shaft

- Production Formula:Available

- Product Length:2440mm-3050mm

- Product Thicknes:40mm-200mm

- Product Width:610mm

- Transport Package:Bulk Packing

- Trademark:OYADE

- Origin:China

- Production Capacity:10set,Year

Description

Width:1220/1200

Thickness: 3-20mm normally, can be adjusted accordingly

Raw Material

High :not less than 7meter

3. Equipment Features

Automatic material feeding -metering system

The raw material of mgo powder, mgo sulfate are feeding-metering-mixing automatically .scientific ratio and accurate weight measurement promise the stable formula;

Beside the silo ,there are dust collector, which can keep the factory very clear

As sawdust perlite, this material is light and easy block, normally will be added by workers into the mixers

Raw material mixing system

1. Double Shaft mixer adopting of most advanced, the most mature colter mixer mixing mechanism and its core technology,and high speed rotating cutter discrete type mixer, fast mixing speed,shows high mixing efficiency of the mixer host.

2.High mixing precision, good workability and evenness of various kinds of materials

3.Pneumatic discharge device. When discharging, there is no dead zone, no residue, no leakage, and discharge time is short.

4.To adjust the mixing time of mixing console according to the testing of the product, and with the highest productivity to meet the requirements of production.

5.Mixing barrel and mixing blade are made of imported alloy wear-resistant plate, high-speed flying cutter is made of wear-resistant alloy castings and has high wear resistance, can improve the service life of the mixing console.

Multifunctional forming system

This part inclues all configuration of automatic feeding slurry, automatic laying cloth, automatic flatting, 5groups of roller, second -pressing.

The production line is high automation, stable operation, specifications can be adjusted as you like. Product surface is smooth and flat, high compactness, truly realized the industrialization of the new decoration panel production line.

Automatic cutting machine

The production speed is determined by the linear cutting speed. With the new equipment, we have updated the cutting technology, and the production capacity of the same thickness has been increased.

Equipment function and characteristics: Exactly cutting the board into designated specification during production flow , no damage to the products and moulds, reducing labor cost and lower working strength.

Mold releasing system of formed sheets

Automatic release the board from PVC mold,and automatic stack the PVC molds,

Regards the board, when we stack the boards, we need to stack with face to face. because if the face to backside, it is easy to scratch the face side. The automatic flip machine makes this part automatic, no need workers do it.

1.A radian between the conveyor belt and output machine can help to make the mgo board and PVC mould to separate more easily . Or else , the Sucker will easy suck the PVC mould and mgo board together .

2.The blowers on the convey line ,can blow the dust on the board and PVC mould .

3.The use of the flip machine and the suction cup machine saves labor

Automatic flip machine.

When we stack the boards, we need to stack with face to face. because if the face to backside, it is easy to scratch the face side. The automatic flip machine makes this part automatic, no need workers do it.

Four-edge cutting machine

cutting the formed board edges, making edge smooth and tidy, reducing error, so as to make the board beautiful.

Precise cutting machine, could cut any special size board, esp for the laminated boards could guarantee the four sides very smooth after cutting

4.Our Advantages1.The structure of the machine is simple and easy to maintain. Extremely low maintenance rate of the consumable parts, and the consumable parts are universal and easy to replace, no specific purchase required.

2.The machine runs stably and the production efficiency is very high. The whole machine uses stainless steel beam bridge to improve the synchronous running stability of the mold, protect the mold, and is very easy to clean.

3.The whole machine use both the shaft and chain hybrid transmission to prevent the stripping and dragging, and improve the product quality and finished product rate.

4.The whole line is made of 304 stainless steel drum the diameter is 240mm, which is suitable for chloride magnesium products, sulfate magnesium products, cement products, non-corrosive and durable, easy to clean.

5.The whole machine line uses well-known brand general-purpose motor, which is easy to maintain and easy to purchase. The power control system use the international brand Siemens and well-known brand inverter mixed control to reduce the failure rate, maintenance rate so that improve production efficiency.

6.According to our 23 years' experience in mgo board field. The automation is the No1 in china, compared to others could help save 30% labor cost.

7.Compare to the old technology, our new solution has higher production capacity. Could produce upto 4000 pieces in 10 hours, higher than the industry standard in this filed.

8.The machine line could be equipped up to three filling materials mixer, could meet the big capacity and the efficiency producing the thick board

9.Equipped automatic flip machine, could stack the board face to face to protect surface. Also could save the labor cost.

10.A set of solutions can produce a variety of plates, whether it is the MgO board or the cement board, to meet the needs of different customers and occupy more market shares

5.Packing & Delivery

1.First use plastic film to wrap and cover the machine 2.Pack small parts in plywood box 3.marked with required label or shipping mark .

4.Use steel wire rope to fix the container ,so as to avoid to damage because of moving

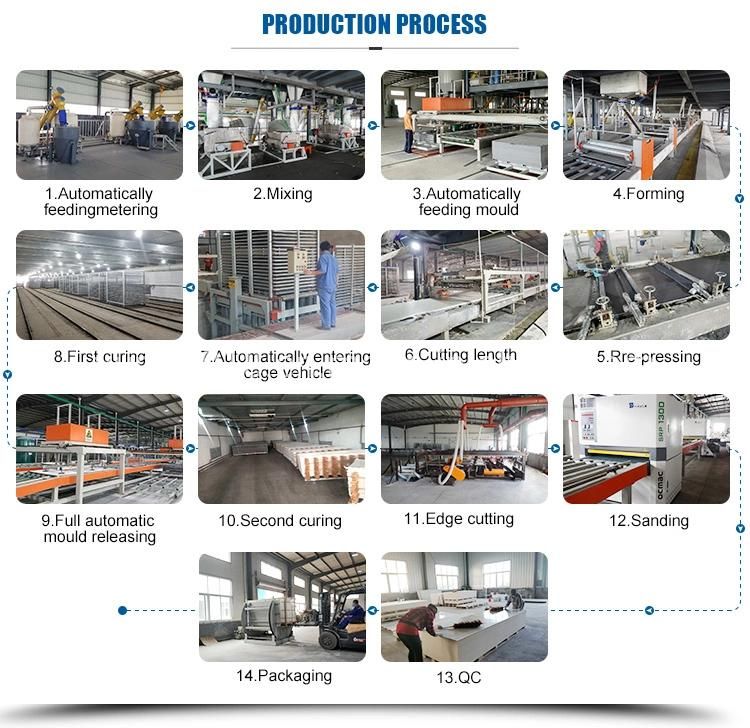

6.Production process

7.Our Factory