Automatic Tile Cutter for Brick and Tile Making Industry.

Xi'an Brictec Engineering Co., Ltd.- After-sales Service:on Site Installation & Commissioning

- Warranty:3 Years

- Certification:ISO9001: 2000

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydroforming

Base Info

- Model NO.:Brictec

- Automation:Automatic

- Brick Raw Material:Clay

- Processing:Brick Production Line

- Method:Hydraulic Pressure

- Product:Brick & Tile

- Tolerance:0.5mm

- Condition:New

- Maximum Stretching Force(Kn):22

- Maximum Single Stroke(mm):2800

- Stretching Speed(M/Min):6

- Transport Package:Sea Worth Container

- Specification:ISO9001,ISO2000

- Trademark:BRICTEC

- Origin:China(Mainland)

- HS Code:84749000

- Production Capacity:10000PCS,H

Description

Basic Info.

Model NO. Brictec Automation Automatic Brick Raw Material Clay Processing Brick Production Line Method Hydraulic Pressure Product Brick & Tile Tolerance 0.5mm Condition New Maximum Stretching Force(Kn) 22 Maximum Single Stroke(mm) 2800 Stretching Speed(M/Min) 6 Transport Package Sea Worth Container Specification ISO9001/ISO2000 Trademark BRICTEC Origin China(Mainland) HS Code 84749000 Production Capacity 10000PCS/HProduct Description

High effienicy clay bricks cutter machine

Product Introlduction:

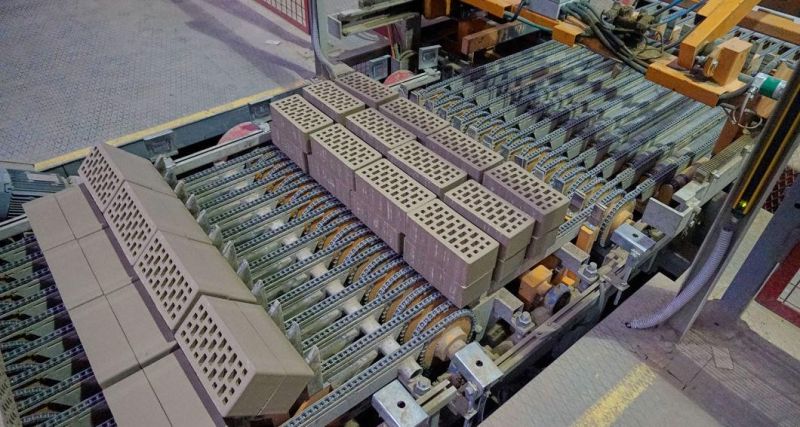

The brick cutter machine is mainly used for cutting adobe bricks into designed specifications with equal length clay column delivered by the column cutter. The double cutting frame is adopted to position accurately, the steel wire is easy to replace, time and labor are saved, the double cutting frame system is adopted to ensure the safety of operators in steel wire replacement, it can adapt to a variety of brick type, the green brick pushing motor USES pneumatic clutch, it does not need to be started frequently, therefore the service life is improved.

.

Brick Cutter Specifications:

| Model | Brick dimensions (single or double column) | Capacity(cut/min.) | Pressure (MPa) | Power (kW) | Dimensions (mm) | Weight(ton) |

| QPJ-I | 240×115×53 | 10-15 | 0.6~0.8 | 11.2 | 6500×2560×1860 | 2.9 |

Brick Cutter Production on site:

Related bricks production line machinery :

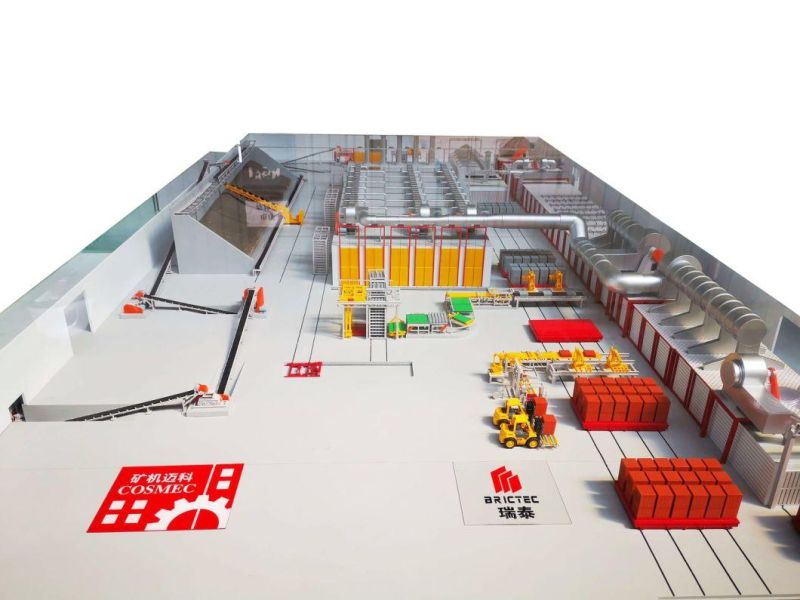

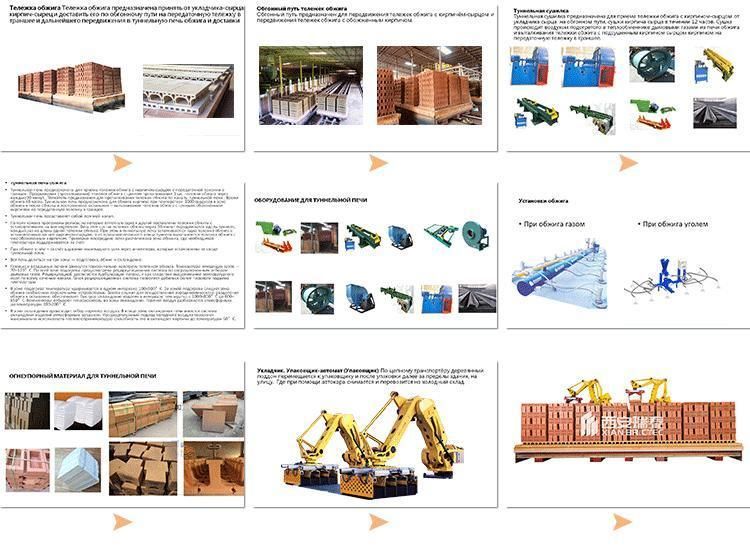

Brick making progress introduction

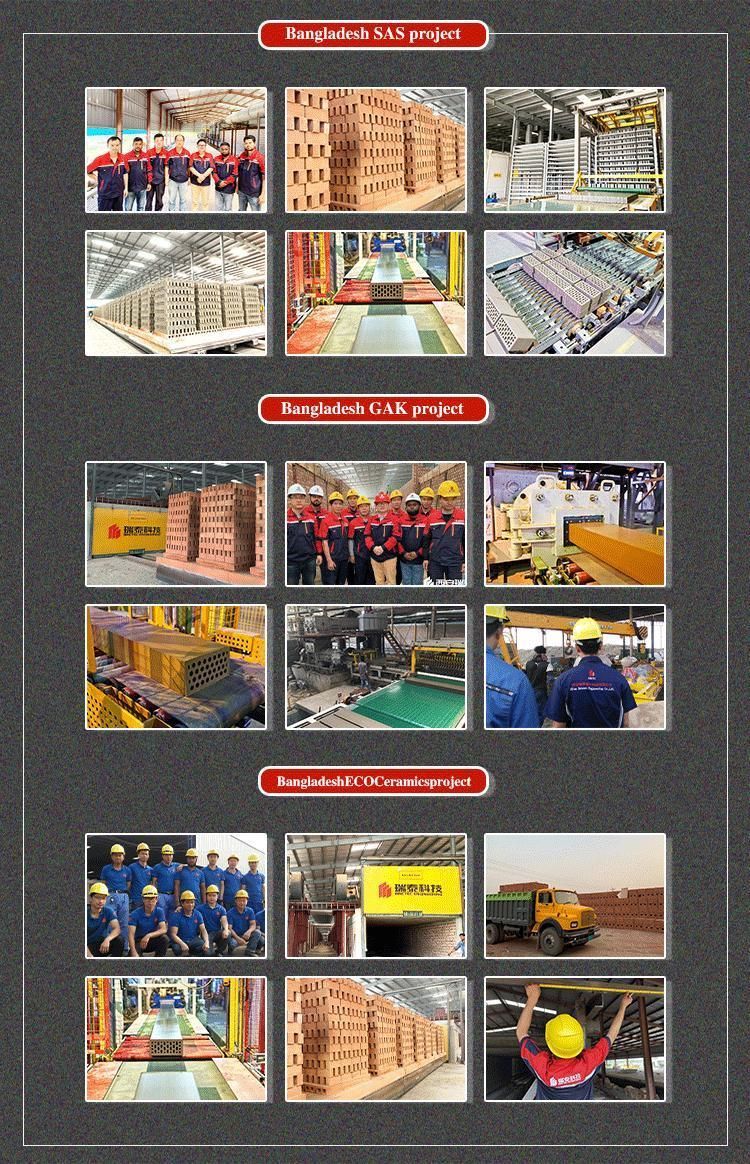

Our projects in Bangladesh

Handover Projects:

- Comprehensive Limited, Tangail [Hoffman Kiln-100,000/day]

- New Generation Clay Bricks, Narayongonj [Hoffman Kiln-50,000/day]

- S.B. Auto Bricks Ltd., Chittagong [Hoffman Kiln-50,000/day]

- G.S.A. Auto Bricks Ltd., Rangpur [Hoffman Kiln-50,000/day]

- Conforce Limited, Savar, Dhaka [Tunnel Kiln-50,000/day]

- Banolata Refractory Ltd., Natore [Hoffman Kiln-50,000/day]

- Kanaipur Auto Bricks Ltd., Faridpur [Hoffman Kiln-50,000/day]

- Pachgaon Auto Bricks Ltd. Tangail, [Hoffman Kiln-50,000/day]

- Paiker Auto Bricks Ltd., Bogra [Tunnel Kiln-100,000/day] (Partial Involvement)

- Alif & Co., Sahapur, Boda, Panchagor [Concrete Block & Pavers-12,800 pcs/hour]

On Going Projects:

- SAS Building Materials Ltd., Comilla [Fully Automatic Computerized Tunnel Kiln-160,000/day]

- G.A.K Auto Bricks [Fully Automatic Computerized Tunnel Kiln-100,000/day]

- Mamun Green Bricks Limited, Shalikha, Magura [Hoffman Kiln-100,000/day]

- Sarker Auto Bricks Limited, Raigonj, Sirajgonj [Hoffman Kiln-100,000/day]

- Jehaan Auto Bricks Ltd., Modhupur , Tangail [Hoffman Kiln-100,000/day]

- A&A Auto Bricks Ind. Ltd., Sahapur, Boda, Panchagor [Hoffman Kiln-100,000/day]

- Alpha Auto Bricks Limited, Jamalpur Sadar, Jamalpur [Hoffman Kiln-50,000/day]

- SD Ceramics LLP, Assam, India [Tunnel Kiln-100,000/day]

- SD Ceramics LLP, Assam, India [Hoffman Kiln-50,000/day]

Company & Service Introduction

1.We majors in the abroad & home fired-brick designing, kiln designing, factory building designing and turn-key project.

2.We have many professional specialists, among which 6 are professor-level engineer and 10 are of high title.

3.We have accomplished over 50 brick projects of engineering, trading, technical support in Asia, Africa and South American countries.

4.We have also successfully constructed over 20 production lines in China.

Before-sale services:

(1) Tell customer how to build a brick plant, the complete plant including three parts, brick shaping machinery, drying and firing.(Confirm clay,power electricity,water,land area, fund)

(2) Guide customers to choose the best and economic plant, recover the investment within short time.

(3) site inspection

(4) We are responsible for the offer, flow chart, and detail specification of each machinery.

In-Sale services:

(1)Quality control must be inspected strictly

(2)In accordance with the agreements stipulated in the contract

After-sale services:

(1) We will send the technicians to guide with device installation, debugging and training operators until customers are fully satisfied.

(2) Guarantee for machinery, materials and equipment supplied under this quotation are valid for a period of 12 months after commissioning or 16 months after delivery whichever is earlier. Warranty shall cover manufacturing defect in material and workmanship but exclude:

1. Daily wear and tear 2.mishandling or improper operation3. Incoming power supply fluctuation

4. Consumable and spare parts.

(3) Regular visit customer, consult with the customer feedback, come true with the customer's two-way communication.