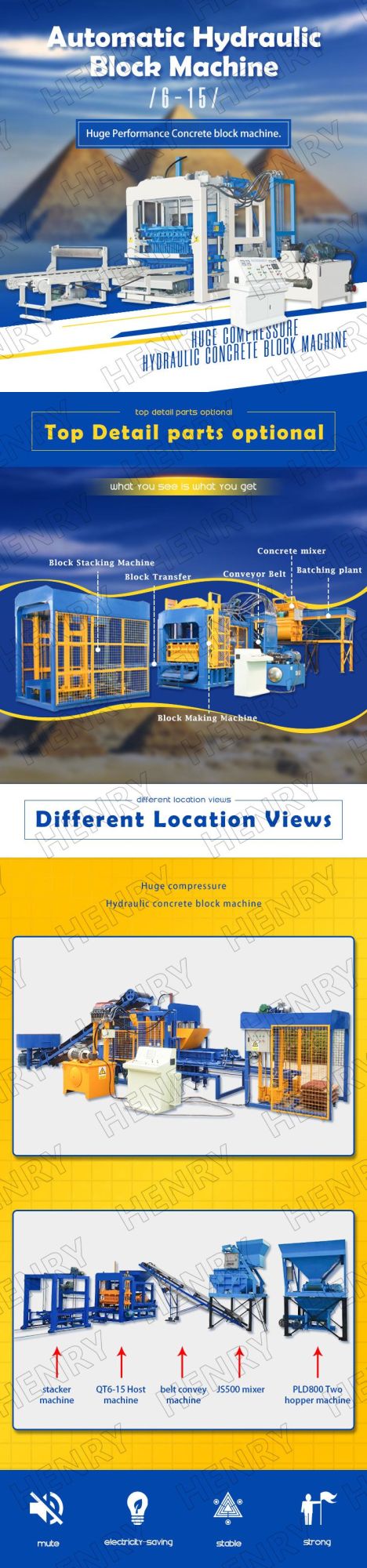

Qt6-15 Fully Automatic Hydraulic Cement Hollow Block Machine Concrete Block Making Machine Paver Machine Curbstone Making Machine Line Booming Business

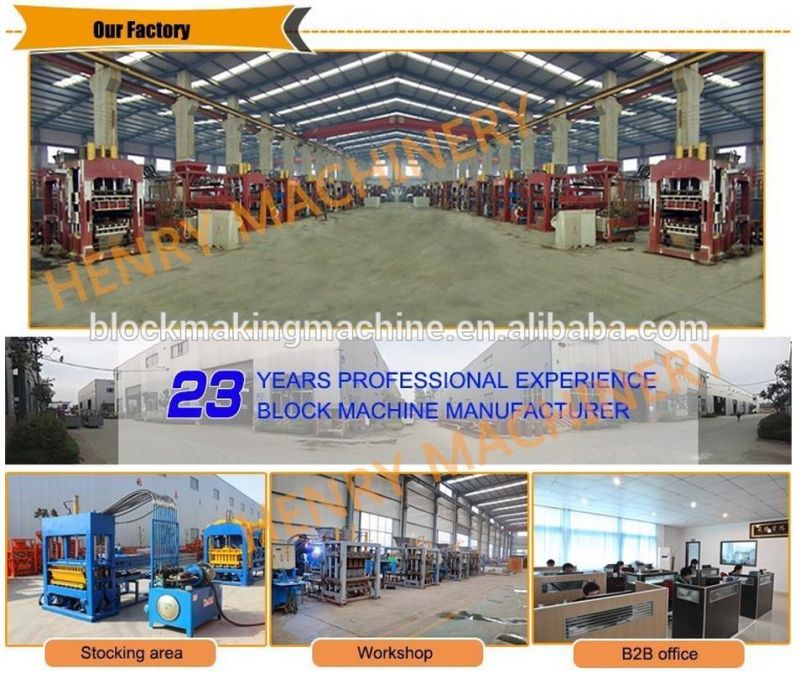

SHANDONG HENRY INTELLIGENT MACHINERY MANUFACTURING CO., LTD.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydraulic Shock

- Pallet Size:1300*900*30mm

- Dimension:3500*2300*2930mm

Base Info

- Model NO.:QT6-15

- Molding Area:1196*880mm

- Moldels of Mixer:Js750

- Viberation Force:100kn

- Transport Package:Nude Package for Full Container

- Specification:9.8T

- Trademark:HENRY

- Origin:Shangdong China

- HS Code:8474802000

- Production Capacity:2100PCS,Hour

Description

Basic Info.

Model NO. QT6-15 Molding Area 1196*880mm Moldels of Mixer Js750 Viberation Force 100kn Transport Package Nude Package for Full Container Specification 9.8T Trademark HENRY Origin Shangdong China HS Code 8474802000 Production Capacity 2100PCS/HourProduct Description

High Production Qt6-15 Fully Automatic Hydraulic Concrete Hollow Block Machine Cement Paver Machine Curbstone Making machine Line

Machine description

Advangtage of QT6-15 High Production Fully Automatic Hydraulic Concrete Hollow Block Machine Cement Paver Machine Curbstone Making Mahcine Line

1. Use Germany Siemens PLC control system and Siemens Touch Screen, use Schneider and Omron relays and contactors:

A. Siemens PLC, with great adaptability, guarantees the stability and reliability of the machine.

B. Visualization touch screen, with easy operation;

C. High-quality electrical components from Schneider and Omron;

2. Use Frequency Conversional Control Technology, which controls the block making:

A. Frequency Conversion Control: guarantees the precise and parallel movement between tamper head and mould, protects the products from transfiguration; increases the production rate by improving the vibrating efficiency;

B. Controls the instantaneous start and stop of the motors, to protect the motor from over-heating caused by constant working;

C. Power saving: 30%;

3. Use Double high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure

A. Buffer the hydraulic cylinder, to protect the cylinder from damage caused by inertia;

B. Guarantee production stability;

4. 360° Multi-Shaft Rotating and Compulsory Feeding:

A. Speedy and rotating feeding, with uniform mixing, to make sure that the density and intensity of the products are guaranteed

B. This uniform feeding is applicable for different kinds of raw materials and moulds;

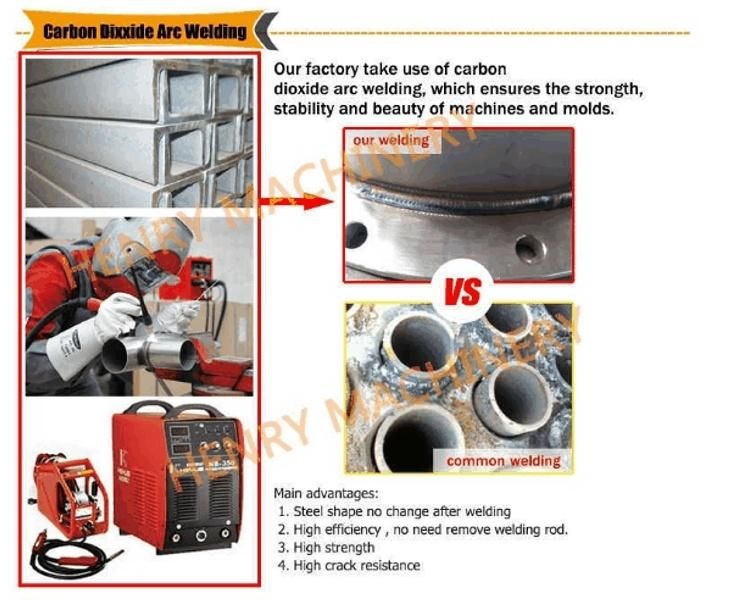

5. Use heat treatment on moulds and main parts of the machines:

A. Heavy duty machine structure and wear resistant moulds;

B. The hardness reaches up to HRC 52-58;

C. Greatly improves the using lifetime of the machine by 50%.

What Features of our QT6-15 automatic concrete block making machine?

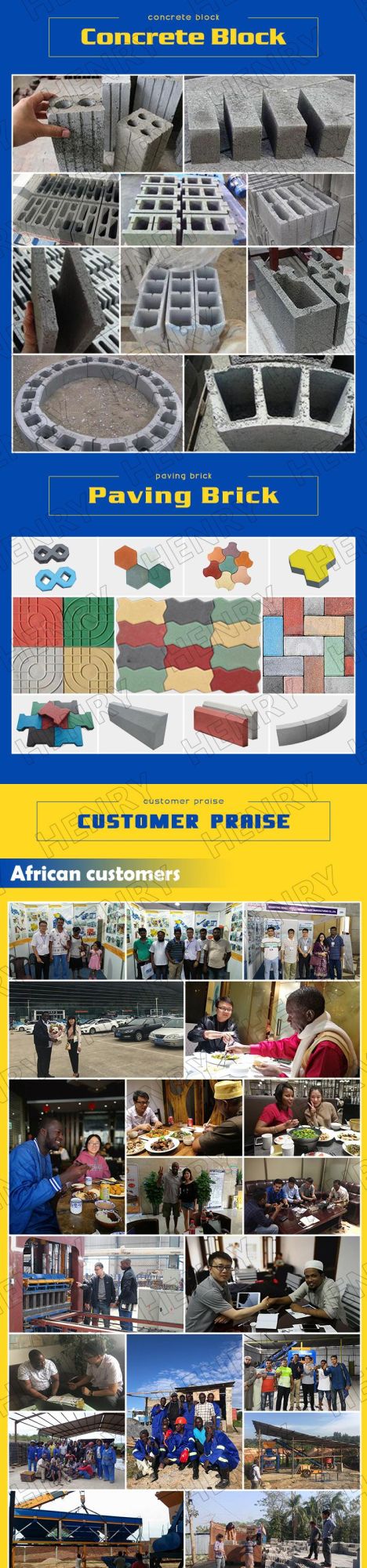

Can produce all kinds of blocks via changing moulds.

- German Siemens motors

- Japan Mitsubishi PLC

- Omron travel switch

- The moulds: We adopt the heat treatment technique to increase the lifespan of the moulds

- Certificates: SGS/CE/ISO9001 2008

- Strong High-Strength Steel Structure

Company View

How to Contact Us?

Jenny Wong

Add;Linyi city, Shandong Province ,China