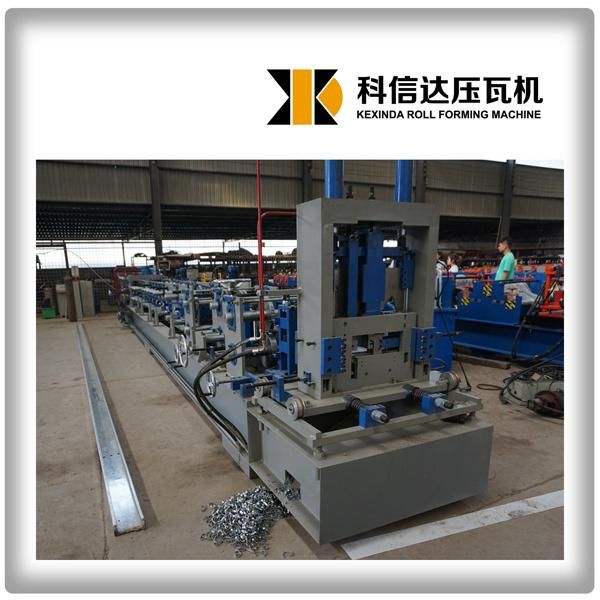

C and Z Interchangeable Purlin Roll Forming Machine

HEBEI XINNUO ROLL FORMING MACHINE CO., LTD.- Warranty:1 Year

- Certification:CE, ISO9001

- Customized:Customized

- Condition:New

- Control Type:Computer Control

- Automatic Grade:Automatic

Base Info

- Model NO.:80-300

- Transport Package:Main Machine Is with Film Package and by Shipping.

- Specification:size: about 9.8*1.65*1.45m

- Trademark:KXD

- Origin:China

- HS Code:8455221000

- Production Capacity:300 Sets,Year

Description

Basic Info.

Model NO. 80-300 Transport Package Main Machine Is with Film Package and by Shipping. Specification size: about 9.8*1.65*1.45m Trademark KXD Origin China HS Code 8455221000 Production Capacity 300 Sets/YearProduct Description

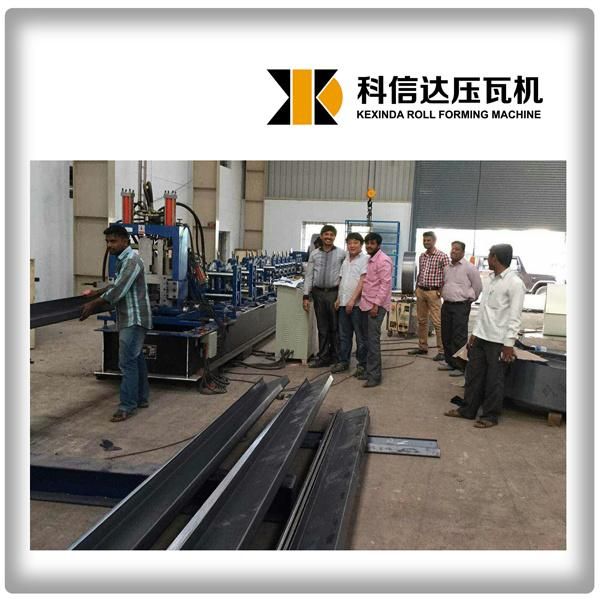

C and Z interchangeable purlin roll forming machineBotou Kexinda Roll Forming Machine Co., Ltd. located in Botou, enjoying convenient and effective transportation for being close to No.104, 106 national road and having Jinghu, Shihuang high speed way through all the area, is the professional manufacturer of metal sheet cold roll forming machines for about 20 years. We not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purlin machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc. Our machines feature beautiful appearance, long service life, good performance, simple operation, reasonable price, good quality.

With the principle of credibility first, mutual benefit and honoring commitment, we can achieve win-win situation.

This machine is full automatic fast-changeable machine. It can produce C and Z two profile. It can change the size and profile fast. The CZ interchangeable machine is more economic and practical than the separate machines. Also it can save more space.

Machine Components and Specification:

(1) Manual Decoiler:

Un-powered; single head;

Max. capacity: 5000kg;

Coil inner-diameter: 508mm

(2) Feeding and Leveling Device:

It used for making the material flat before feeding into the roll forming machine.

(3) Rolling Forming Device:

| 1 | Suitable material | Cold-rolled steel strip and heat-treated galvanized steel strip |

| 2 | Main motor type | Three-phase asynchronous motor |

| 3 | Motor power | 18.5kw |

| 4 | Thickness of raw material | 1.0-3.0mm |

| 5 | Speed of forming | 15-20m/min (according to punching) |

| 6 | Processing precision within | 1.0mm |

| 7 | Material of roller | GCr15 |

| 8 | Roller stations | 18 groups |

| 9 | Material of main shaft | 40Cr (The main shaft have the high frequency grinding &heat Treatment and the surface of shaft is chroming) |

| 10 | Diameter of main shaft | ø70mm |

(4) Hydraulic Punching and Cutting:

| 1 | Material of cutting die | Cr12 |

| 2 | Material of punching die | Cr12 |

| 3 | Hydraulic power | 5.5kw |

| 4 | Hydraulic Pressure | 16Mpa |

(5) Control System:

| 1 | Control system | PLC |

| 2 | Voltage | 380V / 3 Phase / 60Hz |

| 3 | Size of PLC | 700mm(L)x1000mm(H)x300mm(W) |

| 4 | PLC Brand | Japan Panasonic |

| 5 | Component | Solenoid valve, Oil hydraulic cylinder, Bearing, Oil pipeline, Touch Screen, Encoder |

(6) Product support frame:

The length of product support frame: 6m