Henry Qt10-15 Zenith Block Machine Full Automatic Block Paver Making Machine

SHANDONG HENRY INTELLIGENT MACHINERY MANUFACTURING CO., LTD.- Certification:CE, ISO

- Customized:Customized

- Automatic Grade:Automatic

- Type:Hydraulic Shock

- Rated Power:37kw

- Vibration Frequency:4500r,Min

Base Info

- Model NO.:Qt10-15

- Pallet Size:1100*550*25

- Worker:3-5

- Processing Method:Hydraulic Pressure

- Capacity:76800PCS,10hrs

- Shaping Cycle:15s

- Transport Package:Container

- Specification:3500*2300*2900mm

- Trademark:henry

- Origin:Shandong, China

- HS Code:8474802000

- Production Capacity:300sets,Month

Description

Advatages & Features of QT10-15 full automatic block paver making machine

1. Specific store material system: store unit can move fore-and-aft. It is very easy to clean up the adding material hopper. The integrative design can provide the accurate of material supply. It can supply material accurate and to make the product density.

2. The specific design of feeding material: It adopts the active forcing arch eccentric feeding material. Under the help of the drapery bar and it can setting the material equality. Adding material device has many mixer forks. When the materials are sent to the moulds box and the mixer fork can be forcing adding material to the mould box. And the material can be set equality instantaneous.

3. Integrated device oil: It adopts the model of the international standards, high life-span, weather-resistant , low energy consumption and also introduce the imported unit. All these are the pledge of the machine. The reasonable design of the oil drawing can make full use of the energy consumption to ninety percent.

4. Computer controller system: imported PLC controller system , person-machine interface, liquid crystal monitor, intellectualized control and self-diagnosis malfunction and distance controller. It is very simple to operate and safe to use.

5. The equipment adopts the durable design and applies the wield craftwork to make it consistence and durable.

6. Two time setting material device and combined double setting material device. It can assemble random to meet the requirement. It is applied to 6cm to 9cm single color and double color products

Machine photos

Production capacity of QT10-15 full automatic block paver making machine

Why choose us

1. Company strength

The company has been put the new technology, new products in the first place,has applied for 23 patents, the patent technology guarantee equipment to be rationality, stability ,reliability,customers have been widely praise and acclaim on it .Company productsare exported to Europe and the United States ,Africa , the Middle East and America more than 100 countries and regions, now has 3 offices in foreign countries, which provide good customer service after sale for foreign customers .

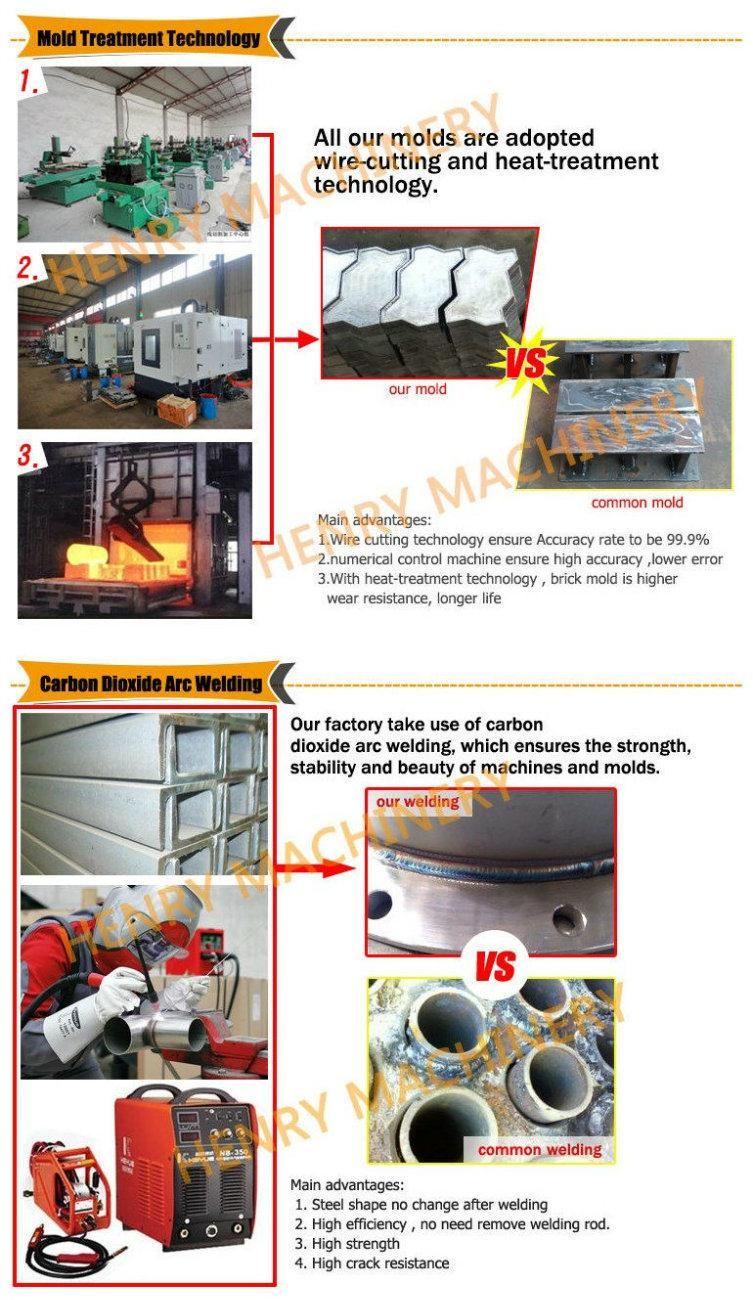

2. Superior technology

Our Service

we have go big after sale service team , they are all the experience technician , over 20 workers have the passport , they all have the oversea experience. So we not only have good service in the pre service , we also think highly of the after sale service.

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line any time, if you need, we can Make invitation

letter for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix, and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time ,keep well communication with each other

Guarantee

(1)We can supply one year guarantee period for our brick making machines,if the client have the question ,they could call our service department number any time , we will supply per day 24 hours service .

(2)Within one year ,if the client meet the unsolvable questions ,we could fly to client place to help.

Please contact with me

Betty

Tel phone:0086-539-8110897

Cell phone:+8618596236109